Heating cooker

A heater and cooker technology, which is applied in microwave heating, electric heating fuel, lighting and heating equipment, etc., can solve the problems of easy rusting and peeling of coated steel plates, so as to reduce electromagnetic wave leakage, improve production efficiency and assembly accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

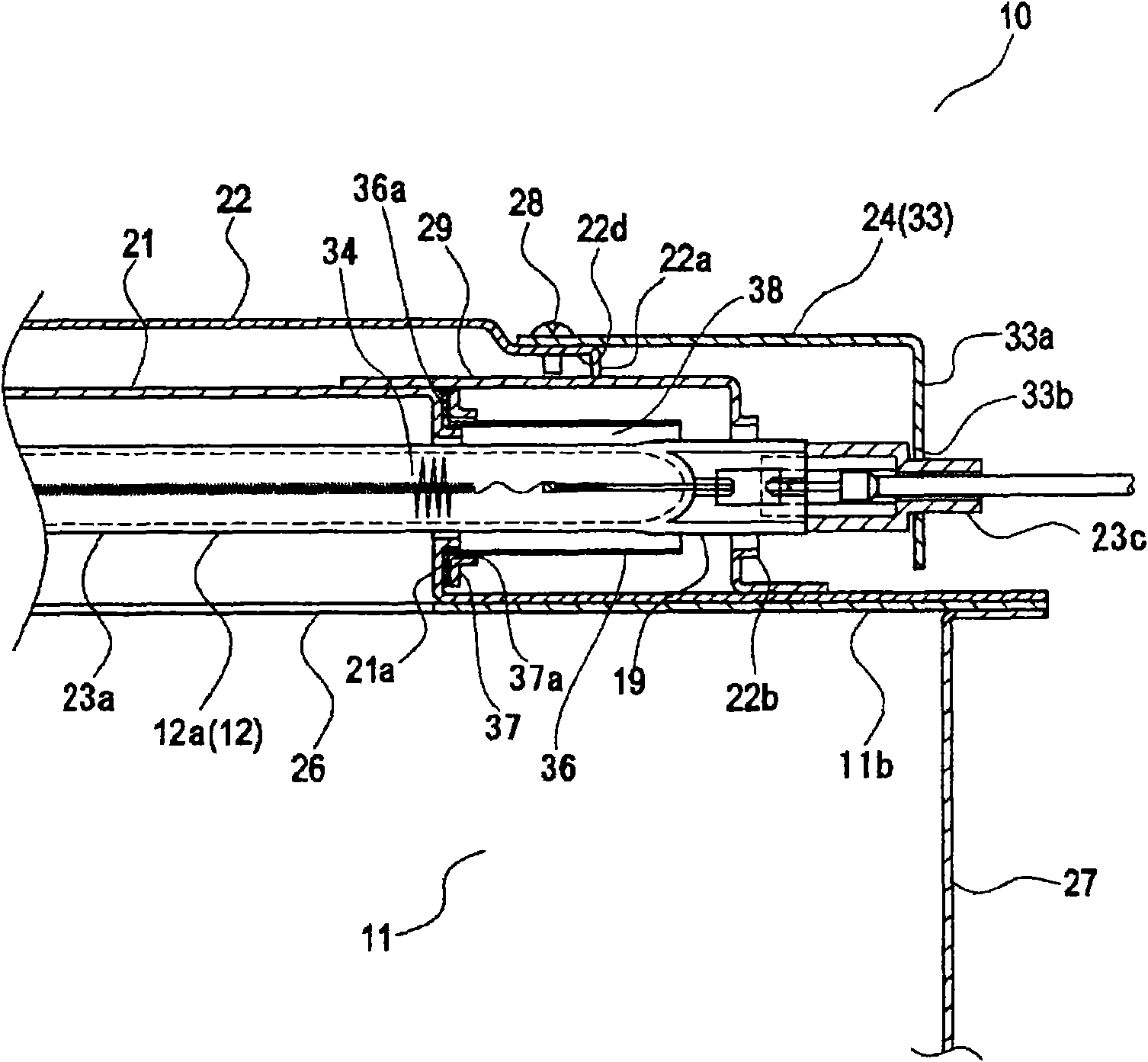

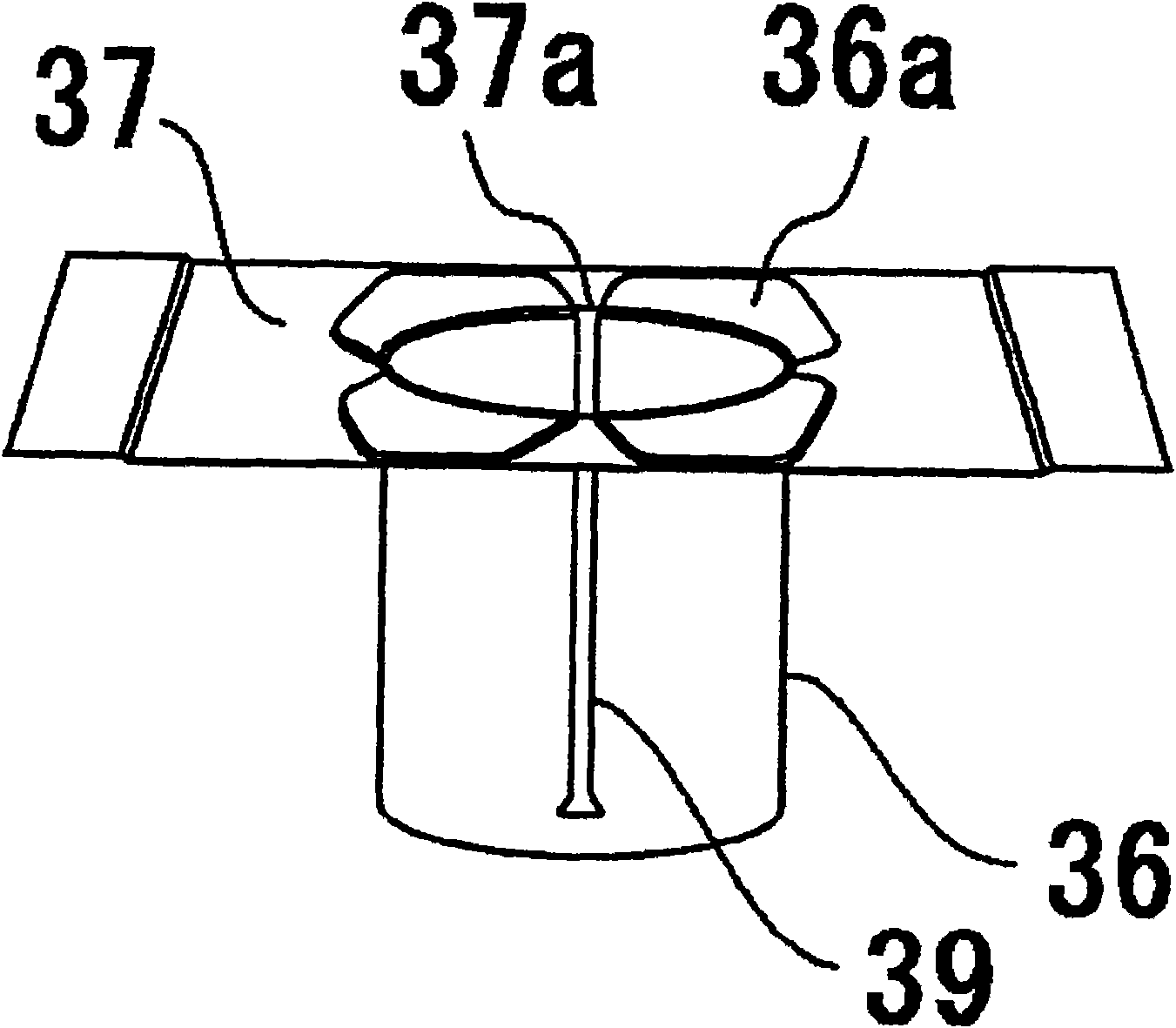

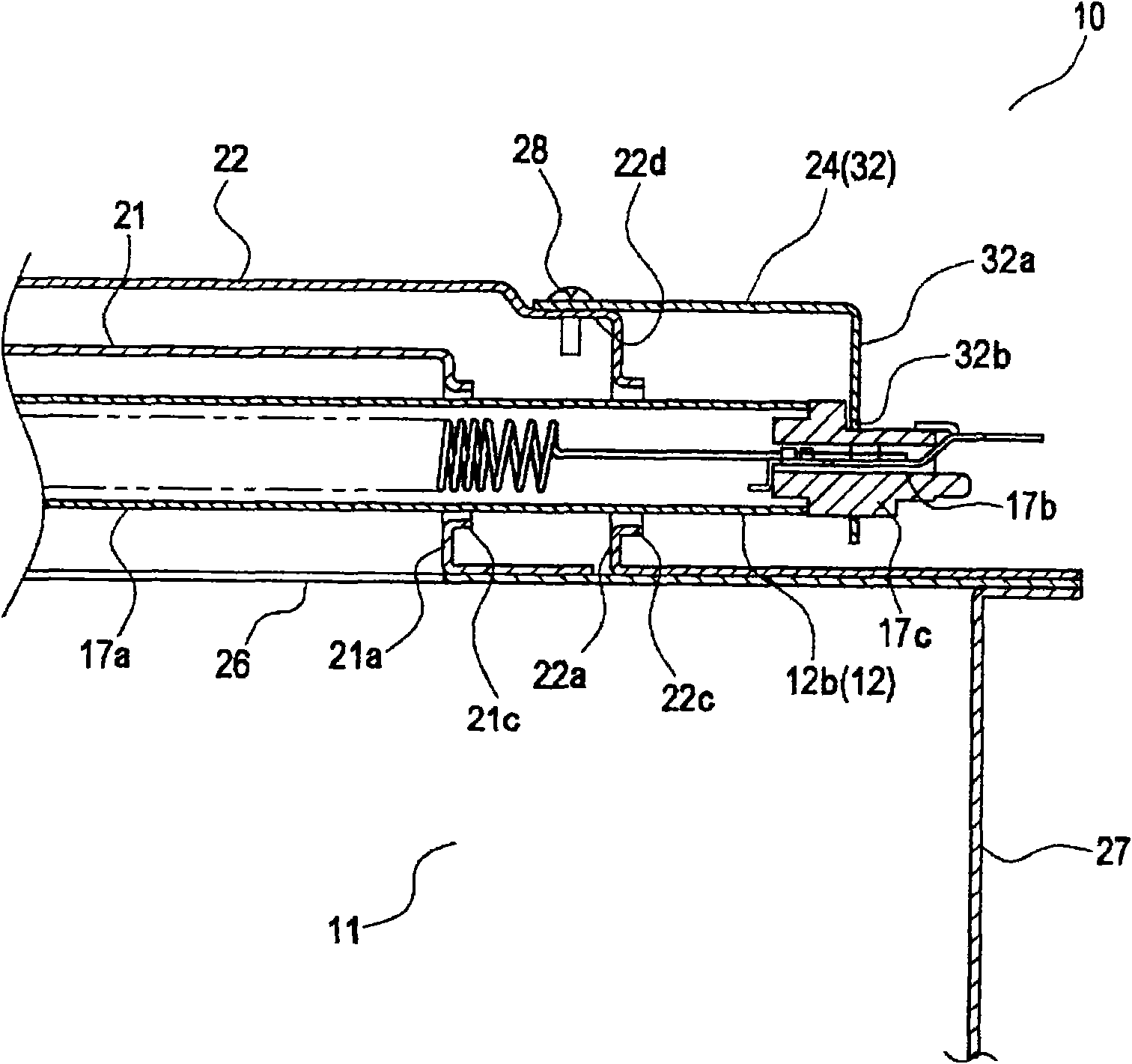

[0028] figure 1 It is a cross-sectional view of the installation part of the tubular heater (argon lamp heater) in this embodiment, showing the structure of the wave choke cavity. figure 2 It is an exploded oblique view showing the structure of the wave choke cavity in this embodiment, image 3 It is a cross-sectional view showing the structure of the installation part of the tubular heater (coil heater) in the heating cooker in this embodiment, Figure 4 It is a top view of the heating chamber in the heating cooker of this embodiment, Figure 5 It is a side sectional view of the heating cooker in this embodiment, Figure 6 It is the front sectional view of the heating cooker in this embodiment. in, figure 1 for along Figure 4 A cross-sectional view of line B-B is shown, image 3 for along Figure 4 A cross-sectional view of line A-A shown in .

[0029] As shown in the accompanying drawings, the heating cooker 10 is provided with: a heating chamber 11 for food to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com