K-shape slipping rail fastener

A rail and sliding technology, applied in the railway field, can solve the problems of not being able to ensure that the dynamic geometric dimensions meet the requirements, fail to meet the requirements of railway operation, and the requirements for the tolerance management value of the static geometric dimensions are getting higher and higher.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

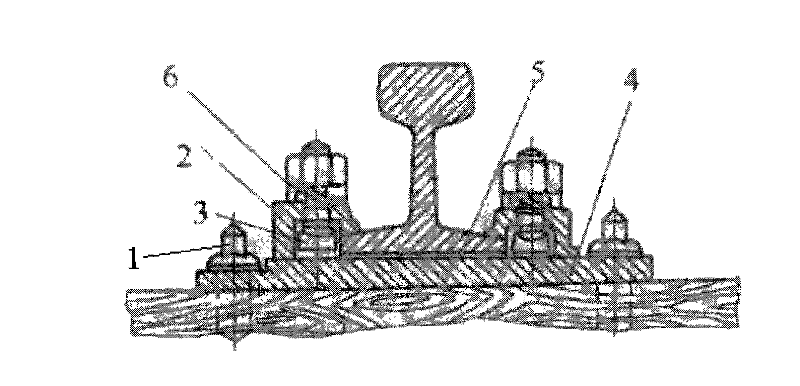

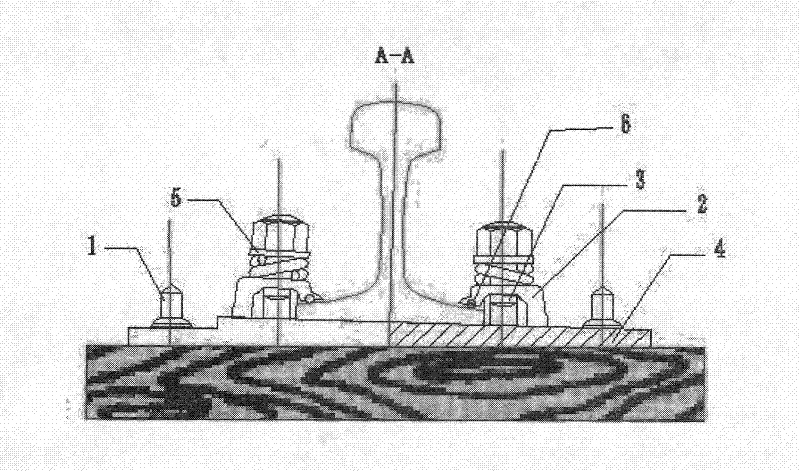

[0019] Embodiment 1: This embodiment is such as Figure 5 with Image 6 As shown, a round hole groove is excavated at the flange (shorter side) of the buckle rail splint. The cross-sectional diameter of the round hole groove is 1-2mm larger than the diameter of the ball. The cross section of the round hole groove is a round platform larger than a semicircle. Fill the hole with some balls (such as Figure 5 ), after filling in the balls, the balls will expose 3-5mm from the flange surface of the buckle rail splint, but the balls will not fall out of the slots. drop.

Embodiment 2

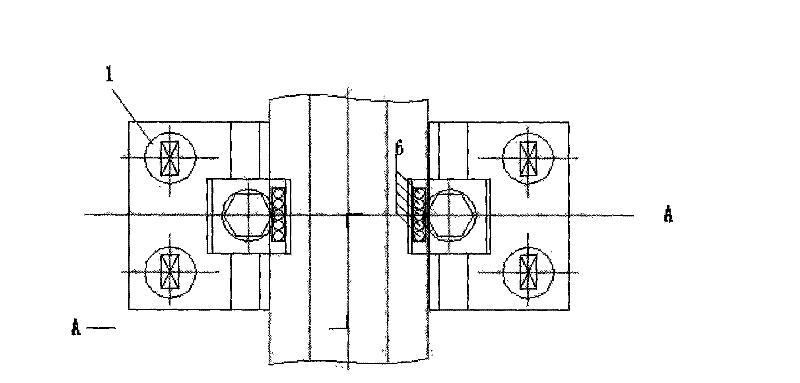

[0020] Embodiment 2: This embodiment is such as Figure 7 with Figure 8 As shown, a slot hole is excavated at the flange (shorter side) of the buckle rail splint, and then a row of ball chains are inserted (the purpose is to isolate the balls), the balls are exposed 3-5mm, and the entrance is plugged with a prefabricated plastic cover , not only to ensure that the ball will not fall out, but also to make it roll freely on the rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com