Door hinge mechanism used for vehicles

A technology of door hinges and hinges, which is applied to hinges with pins, door/window accessories, building structures, etc. It can solve the problems of increased production costs and high mold costs, so as to prevent car doors from sagging, reduce mold costs, and improve load-bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

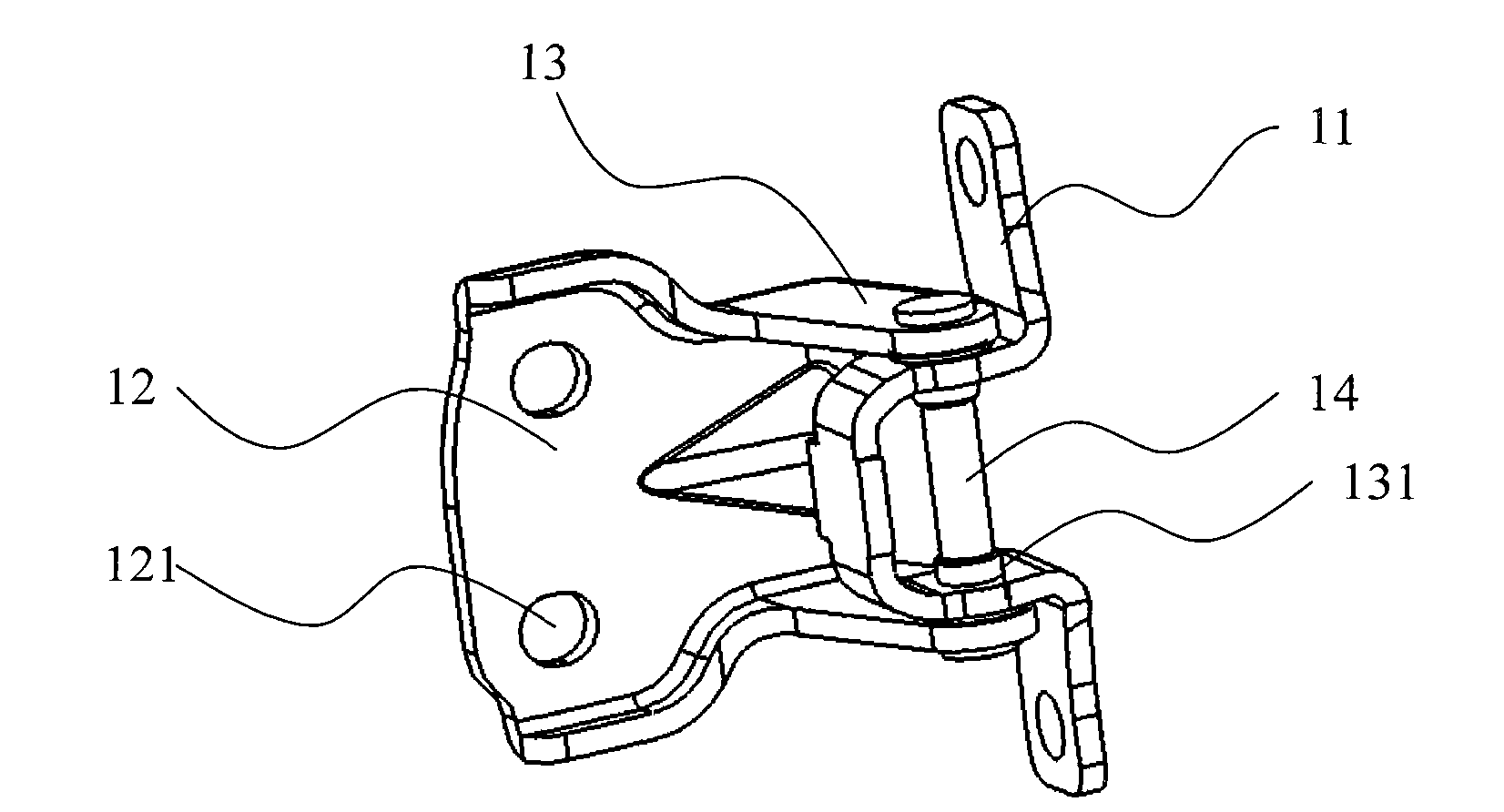

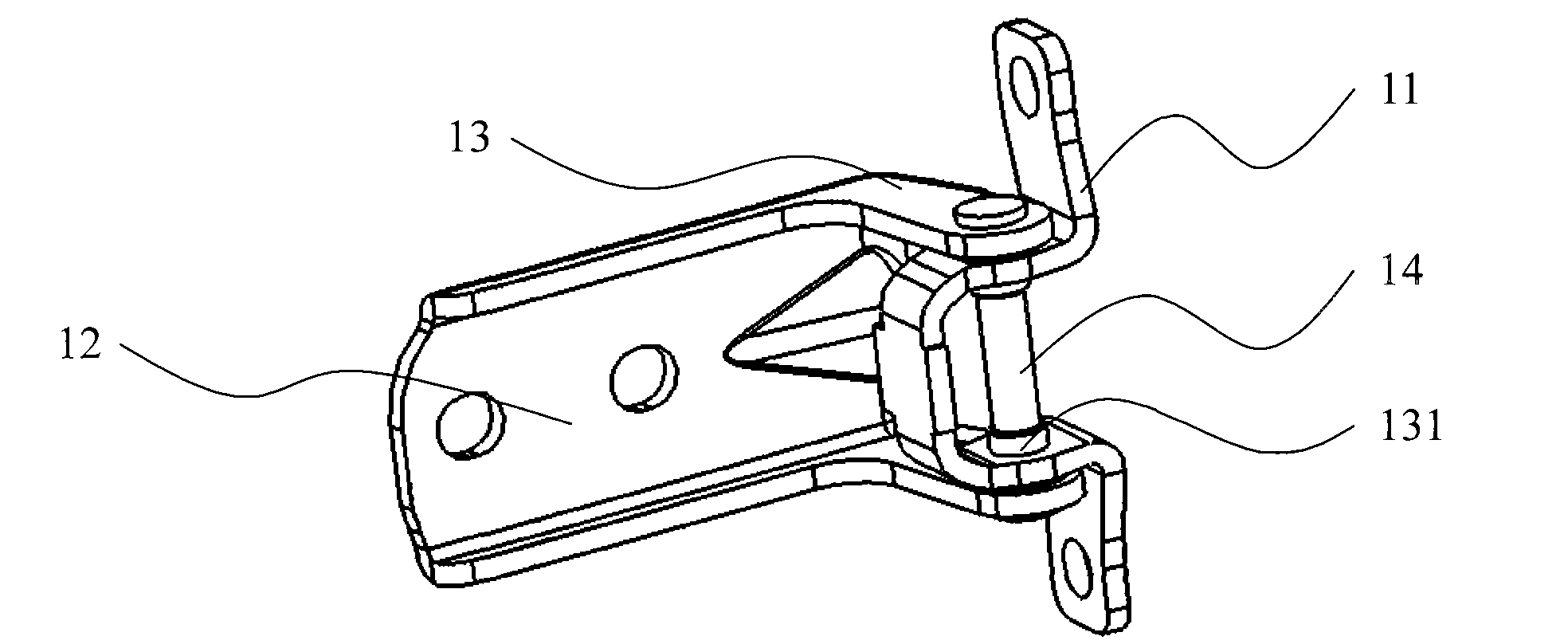

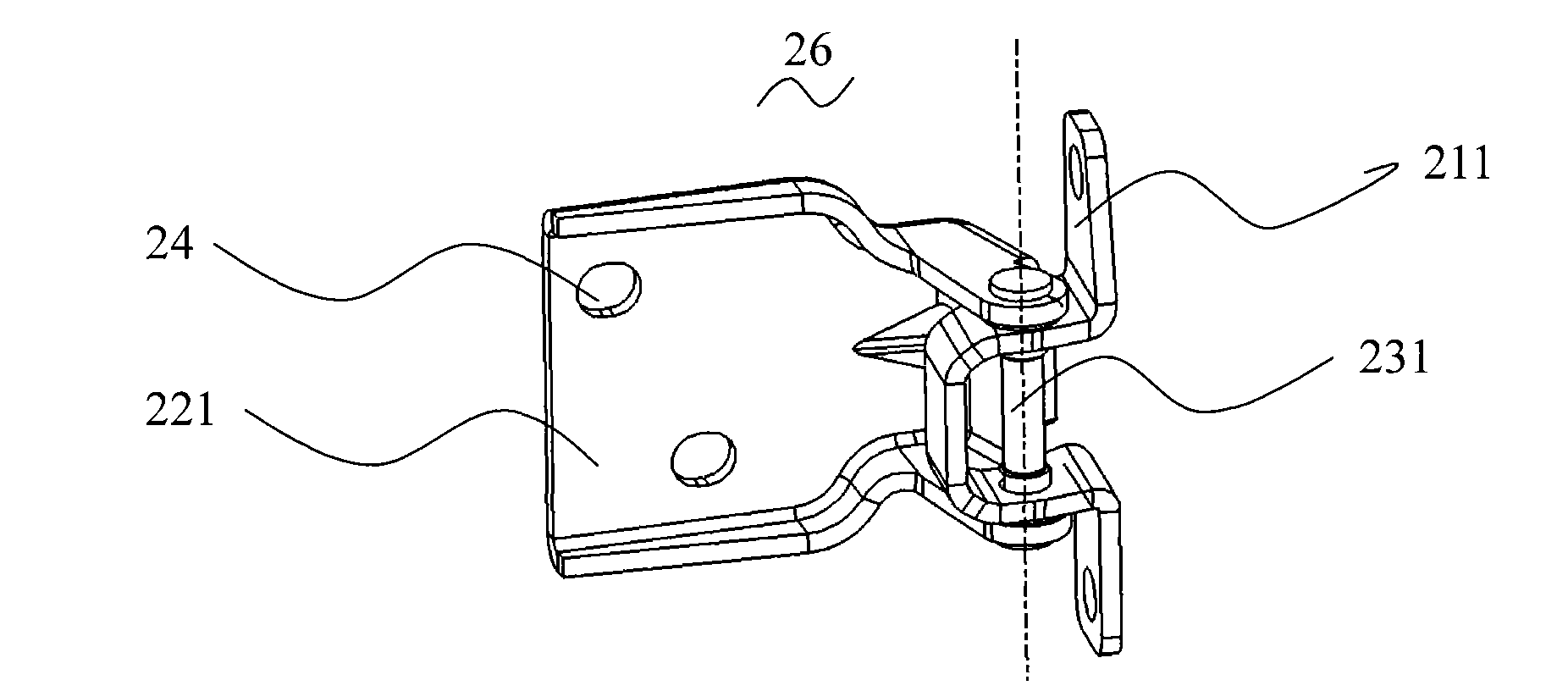

[0021] Such as Figure 3 to Figure 6 As shown, a door hinge mechanism for a vehicle includes a main hinge 21 for connecting the door, a secondary hinge 22 for connecting the vehicle body, and a pin shaft connecting the main hinge 21 and the secondary hinge 22 23. The main hinge 21 rotates around the pin shaft 23 relative to the secondary hinge 22; two mounting holes 24 are arranged on the secondary hinge 22, and the secondary hinge 22 is fixed on the vehicle body through the mounting holes 24; The main hinge 21 is a pair of first main hinge 211 and second main hinge 212 with the same structure; the secondary hinge 22 is a pair of first secondary hinge 221 and second secondary hinge 222 with the same structure. The first auxiliary hinge 221 and the second auxiliary hinge 222 manufacture the mounting holes; the pin shaft 23 is a pair of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com