Mechanical-hydraulic interactive continuously variable transmission

A continuously variable transmission, interactive technology, used in mechanical equipment, transmission devices, fluid transmission devices, etc., to achieve the effects of excellent high-speed transmission performance, control of heat generation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

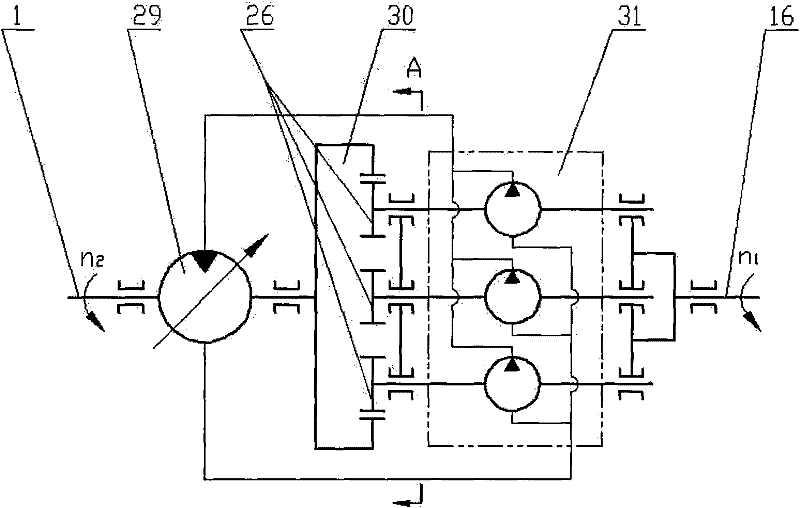

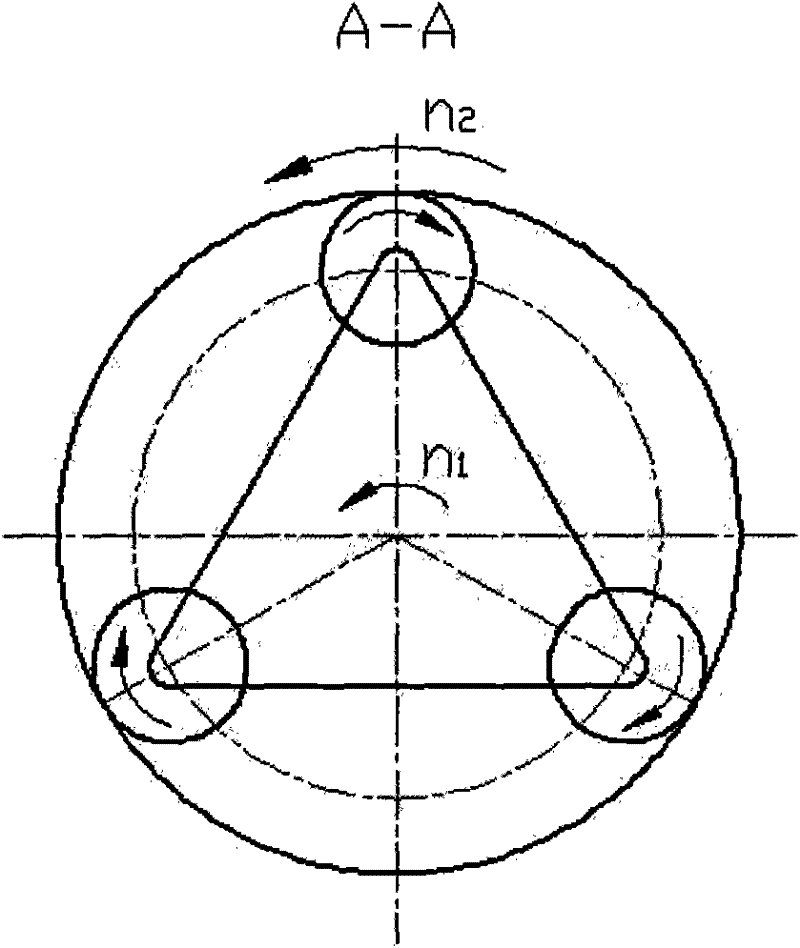

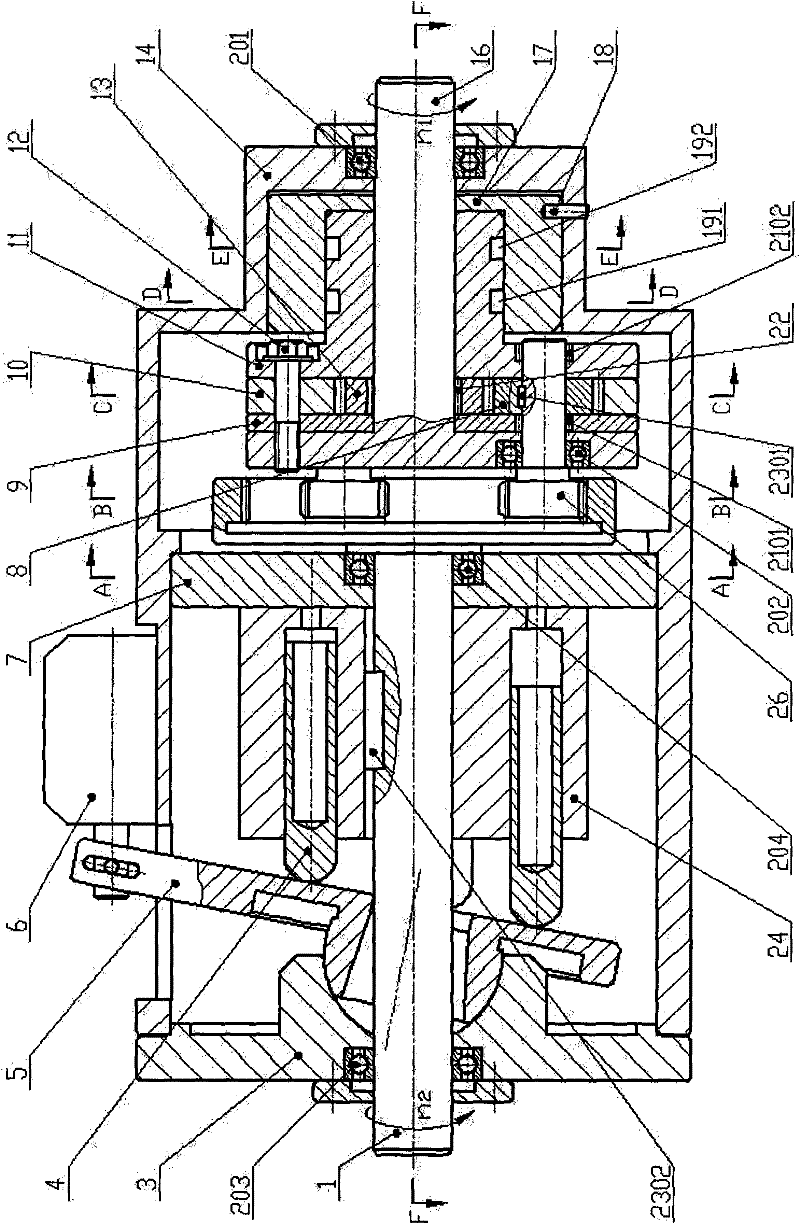

[0060] The present invention is characterized in that it contains: an input part 16, an output part 1, a planetary gear transmission part 30, a combined hydraulic pump 31 and a variable hydraulic motor. The basic working principle of the present invention is that after the input shaft 16 inputs power, the output shaft 1 does not necessarily rotate or slowly rotate due to the effect of the load. At the same time, it rotates at a higher speed. From the analysis of the motion relationship of the planetary shaft gear 26 relative to the ring gear, it can be seen that when the rotational speed of the input shaft 16 driving the planetary shaft gear 26 to revolve is constant, the slower the rotation speed of the planetary shaft gear 26, the faster the rotational speed of the output shaft 1, When the rotation speed of the planetary shaft gear 26 is zero, the rotational speed of the output shaft 1 is equal to the rotational speed of the input shaft 16 , and the transmission speed ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com