A cvt electronic control system and method

An electronic control system and motor control technology, applied in the direction of DC motor rotation control, transmission control, and components with teeth, etc., can solve the problems of low reliability, increased energy loss of hydraulic system, high cost, etc., to achieve Ease of maintenance by after-sales personnel, improve safety, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

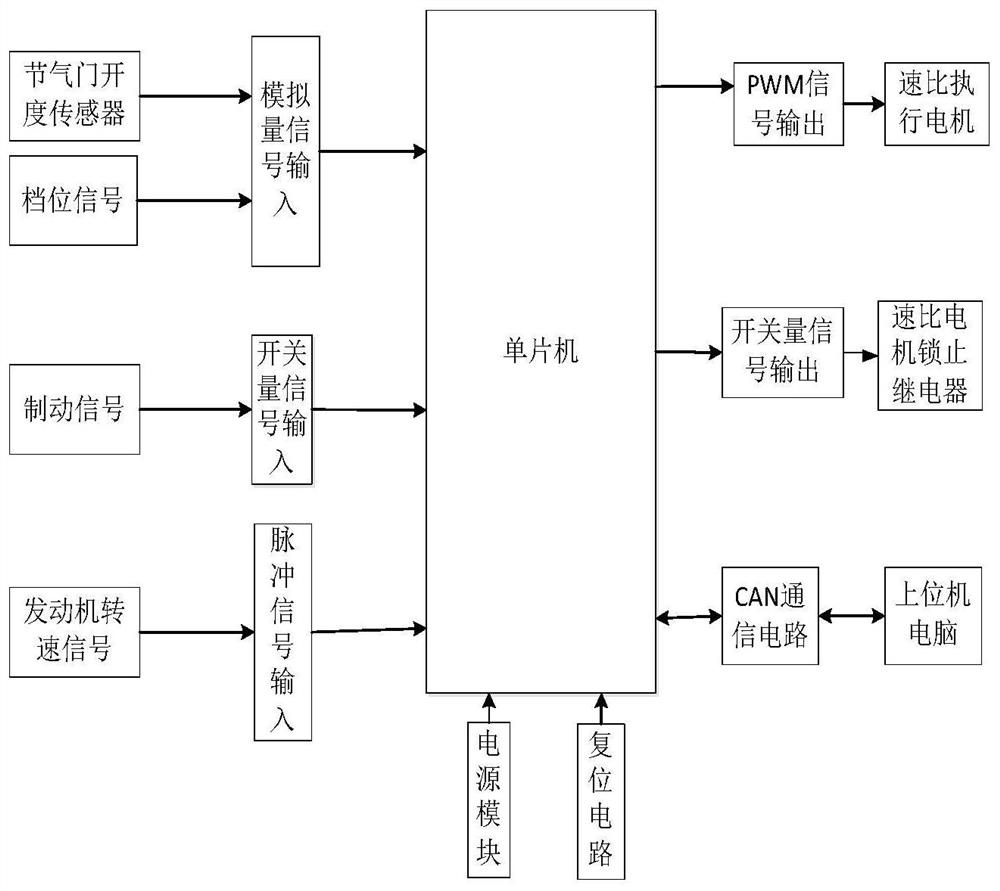

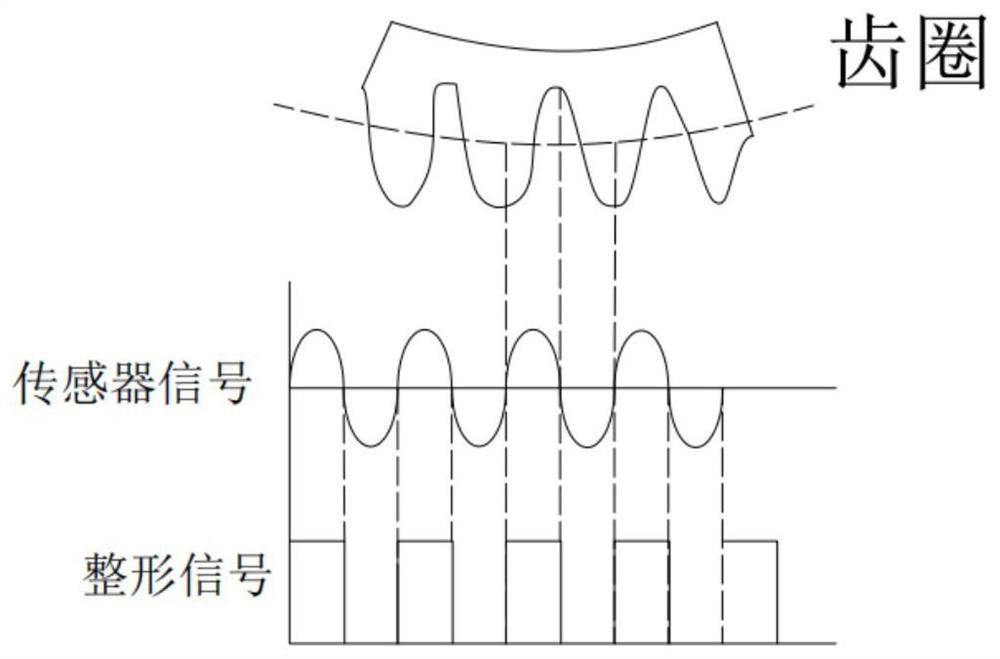

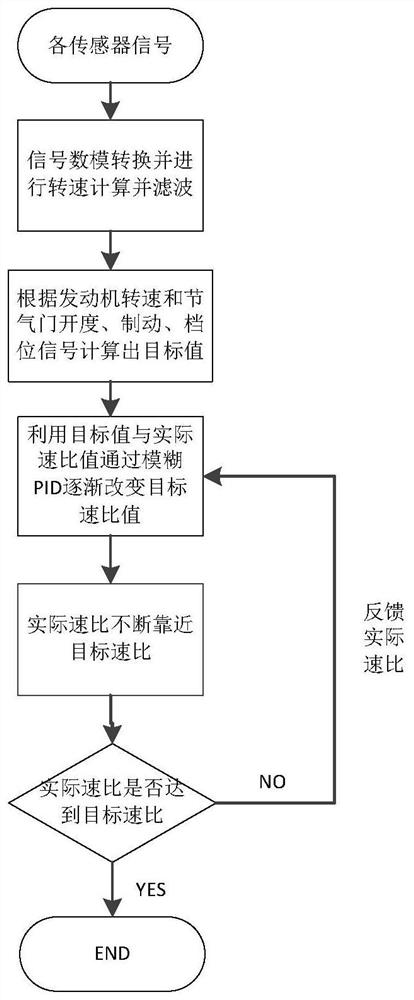

[0037] Such as figure 1 As shown, the present invention utilizes the input throttle switch signal and the analog signal of the gear position signal to carry out digital-to-analog conversion; the brake signal is a switch signal converted by a switch signal circuit; The measurement circuit is converted, and the period method is used at low speed and the frequency method is used at high speed for numerical conversion. After inputting into the microcontroller, the target speed ratio is calculated through an algorithm according to various conversion signals and switch signals. Then output the target speed ratio value to the speed ratio executive motor, so that the actual speed ratio value is constantly approaching the target speed ratio value, and then the actual speed ratio value is continuously fed back to the single chip microcomputer for closed-loop control. Realize the balance between engine output torque and driving resistance, so that the engine can always be maintained in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com