Kovar-based layered composite material for solar cell array interconnection sheet and preparation process of Kovar-based layered composite material

A solar cell array and composite material technology, which is applied in the field of silver/4J29/silver metal-based composite materials and preparation technology, can solve the problems of no protective effect of oxide film, poor molybdenum cold working shape, poor molybdenum weldability, etc. Achieve the effect of large difference in deformation resistance, large difference in recrystallization temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

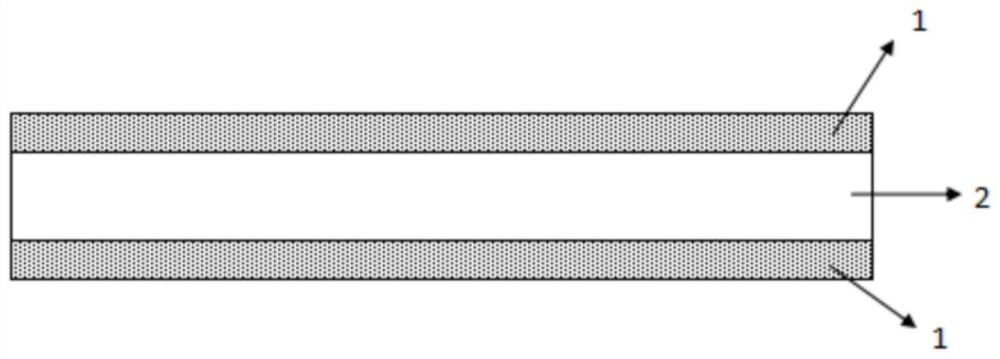

[0028] The invention proposes a metal-based composite material for a solar cell array interconnect sheet, such as figure 1 As shown, the composite material is a three-layer layered structure with a total width of 25 mm and a total thickness of 26 μm, in which the first and third layers are both silver layers 1 with a thickness of 7 μm, and the oxygen content is lower than 50 ppm. The layer is 4J29 alloy layer 2 with a thickness of 12 μm.

[0029] The present invention also proposes a preparation process of a metal-based composite material for a solar cell array interconnect sheet, comprising the following steps:

[0030] Step 1: Put the pure silver plate with a purity greater than 99.99% through two vacuum smelting methods to smelt the silver plate with an oxygen content lower than 50ppm. The vacuum degree of the smelting equipment during the vacuum smelting process is not less than 10 -2 Pa. The above-mentioned silver plates are processed into silver strips with a thickness...

Embodiment 2

[0036] The present invention provides a kovar-based composite material for interconnecting sheets of solar cell arrays, such as figure 1 As shown, the composite material is a three-layer layered structure with a total width of 25 mm and a total thickness of 44 μm, in which the first and third layers are both silver layers 1 with a thickness of 7 μm and an oxygen content of less than 50 ppm. The layer is 4J29 alloy layer 2 with a thickness of 30 μm.

[0037] The present invention also proposes a preparation process of the metal-based composite material for the solar cell array interconnection sheet, comprising the following steps:

[0038] In step 1, the pure silver plate with a purity greater than 99.99% is smelted through three vacuum smelting methods, and the silver plate with an oxygen content lower than 50 ppm is smelted. The vacuum degree of the smelting equipment in the vacuum smelting process is not less than 10. -2 Pa. The above-mentioned silver plate is processed in...

Embodiment 3

[0044] The present invention proposes a metal-based composite material for interconnecting sheets of solar cell arrays, such as figure 1 As shown, the composite material is a three-layer layered structure with a total width of 100mm and a total thickness of 26μm, in which the first and third layers are both silver layers 1 with a thickness of 7μm and an oxygen content of less than 50ppm. The layer is 4J29 alloy layer 2 with a thickness of 12 μm.

[0045] The present invention also proposes a preparation process of the metal-based composite material for the solar cell array interconnection sheet, comprising the following steps:

[0046] In step 1, the pure silver plate with a purity greater than 99.99% is smelted through three vacuum smelting methods, and the silver plate with an oxygen content lower than 50 ppm is smelted. The vacuum degree of the smelting equipment in the vacuum smelting process is not less than 10. -2 Pa. The above-mentioned silver plate is processed into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com