A pressure continuously variable transmission based on nw type double planetary gear structure

A double planetary gear and continuously variable transmission technology, applied in belt/chain/gear, clutch, fluid-driven clutch, etc., can solve the problems of reduced motor shaft life, difficult maintenance and repair, harmonic pollution of power grid, etc., to reduce self-weight , The overall structure is simple and compact, and the effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

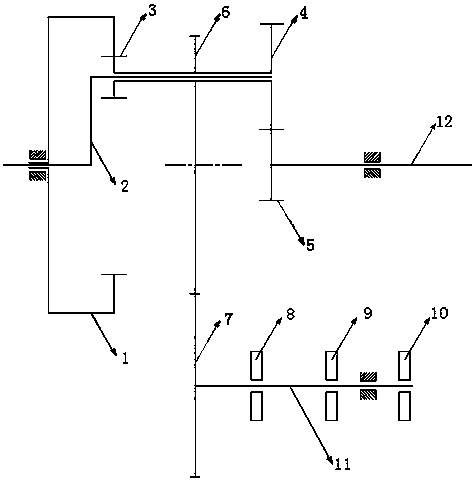

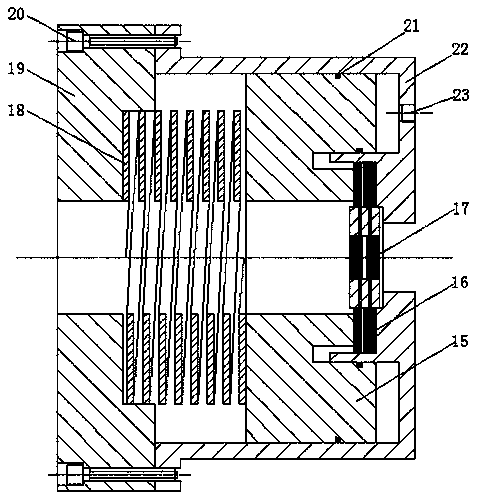

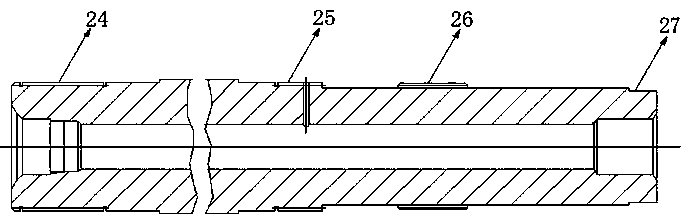

[0042] Specific implementation of a pressure continuously variable transmission based on the NW-type double planetary gear structure, in which each component is made of standard parts made of metal and rubber materials. Skilled technicians can follow the attached Image 6 An example of assembly production is shown. The order of connection from left to right is: pulley 14, frame, ring gear 1, three evenly distributed small planetary gears 3, eccentric gear 6, output gear 7, three evenly distributed large planetary gears 4, planets Shaft 2, sun gear 5, and output shaft 12, hydraulic clutch 8, hydraulic motor 9, pressure sensor 10 and hollow drive shaft 11. The frame is composed of a fixed shell and a rotating body inside. Three planetary shafts 2 are evenly distributed along the circumference of the rotating body. They rotate together with the rotating body. The three small planetary wheels 3 and the large planetary wheel 4 pass heat The sleeves are fitted into a double planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com