Automatic wheelchair handle

A technology for handles and wheelchairs, which can be used in patient chairs or special transportation tools, vehicle ambulance, medical transportation, etc. It can solve the problems of impractical glue, etc., and achieve the effects of easy control, functional optimization, and reduced push resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

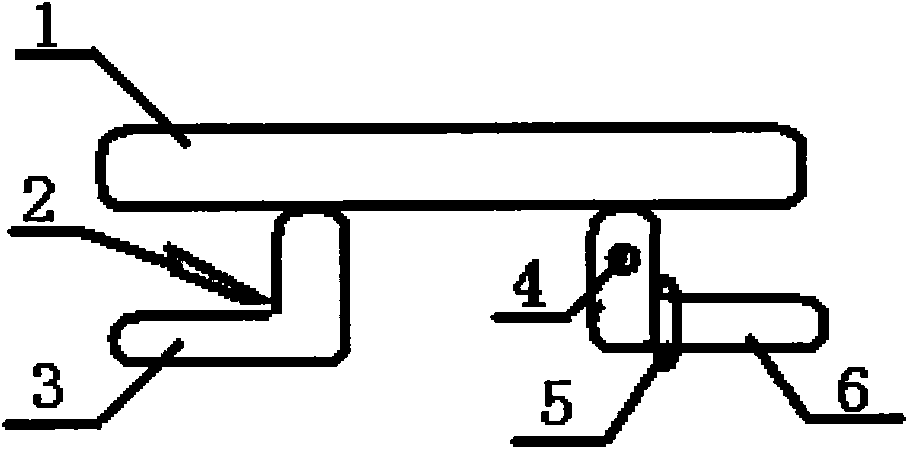

[0010] Below in conjunction with the accompanying drawings the present invention is further described: the handle behind the wheelchair back 1 is placed in parallel to the back of the chair, the right handle 6 is provided with a rotary governor 5, and the column of the right handle 6 is also provided with a knob lock 4 There is a handbrake 2 under the left handle 3. When the speed needs to be adjusted, just turn the rotary governor 5 on the right handle 6 to adjust to a suitable speed, and the wheelchair will advance at a constant speed at this speed. When the knob lock 4 is locked , that is, speed regulation cannot be performed.

[0011] Applying the present invention to the handle, the function of the handle of the wheelchair is optimized, and a speed control handle is provided, so that people can reduce the push resistance when pushing the wheelchair, and at the same time, it is easy to control, and the knob can also reduce misuse by other people The inconvenience caused is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com