Connecting clamp

A technology for connecting fixtures and fixtures, applied in building components, walls, buildings, etc., can solve the problems of complicated installation process, restricting the development of glass curtain walls, and the difficulty of connecting fixtures to meet the glass clamping function of special-shaped curtain walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a connecting jig, which can meet the needs of connecting various plate-shaped objects with different shapes and reduce the difficulty in the process of connecting various plate-shaped objects with different shapes.

[0031] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

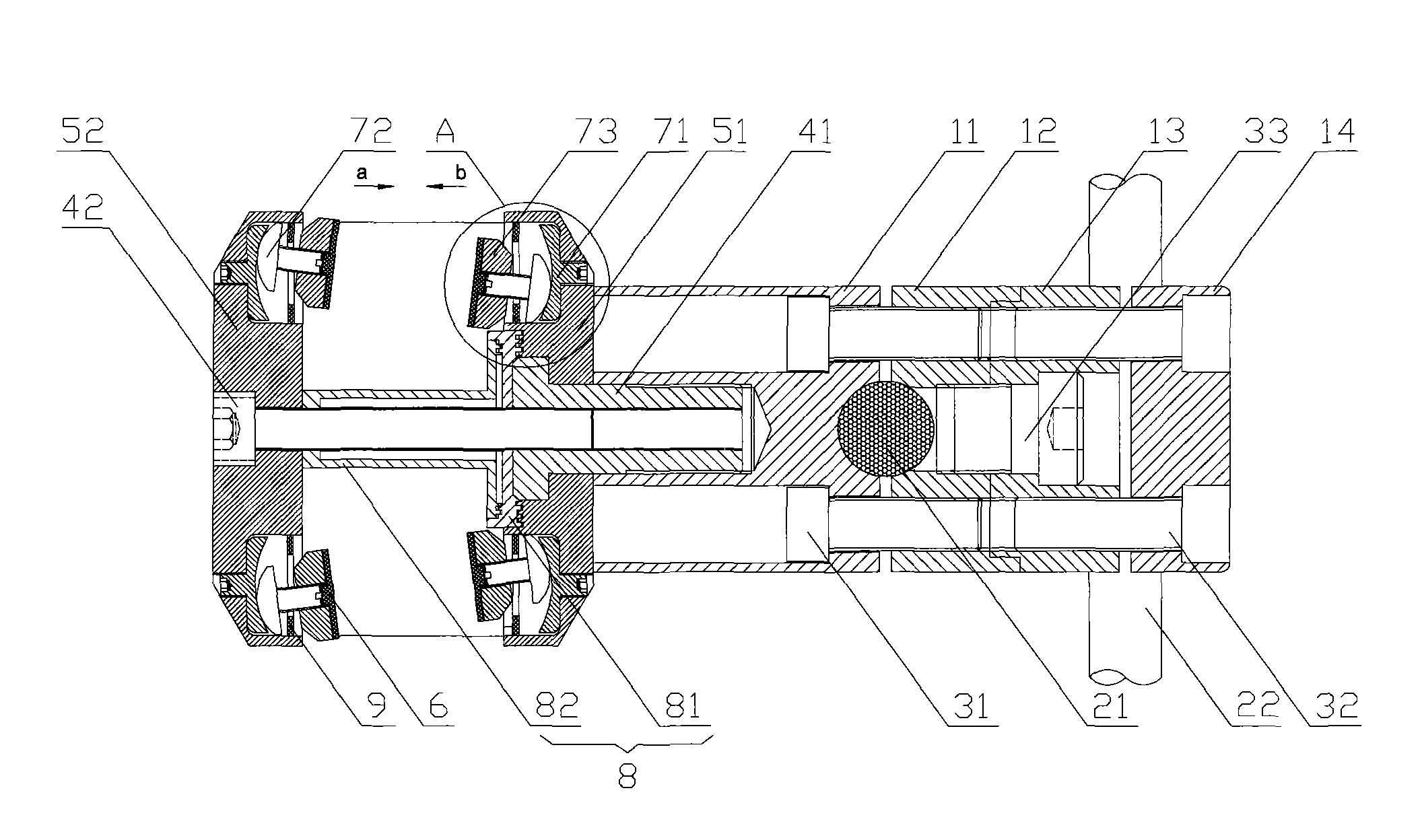

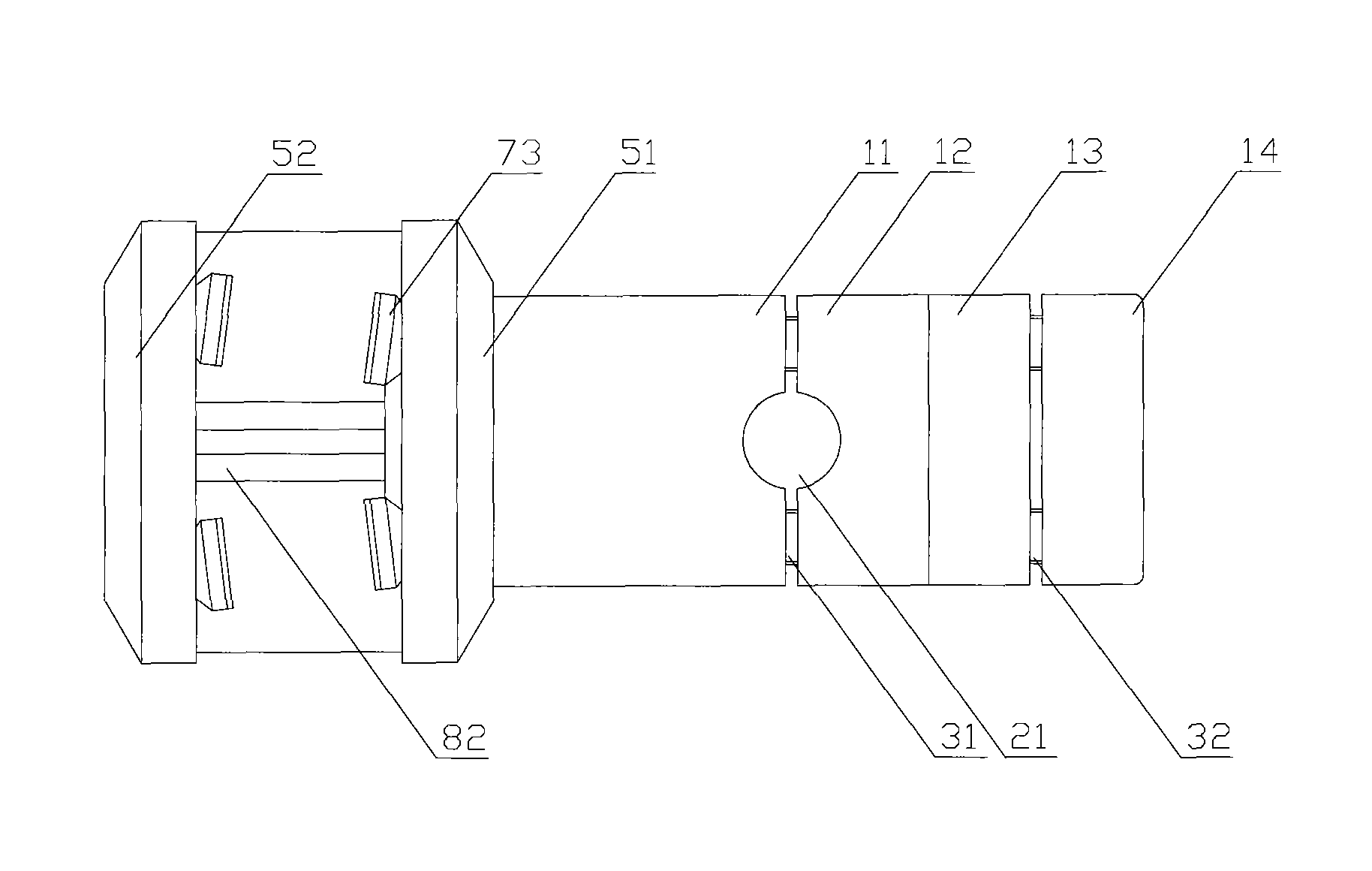

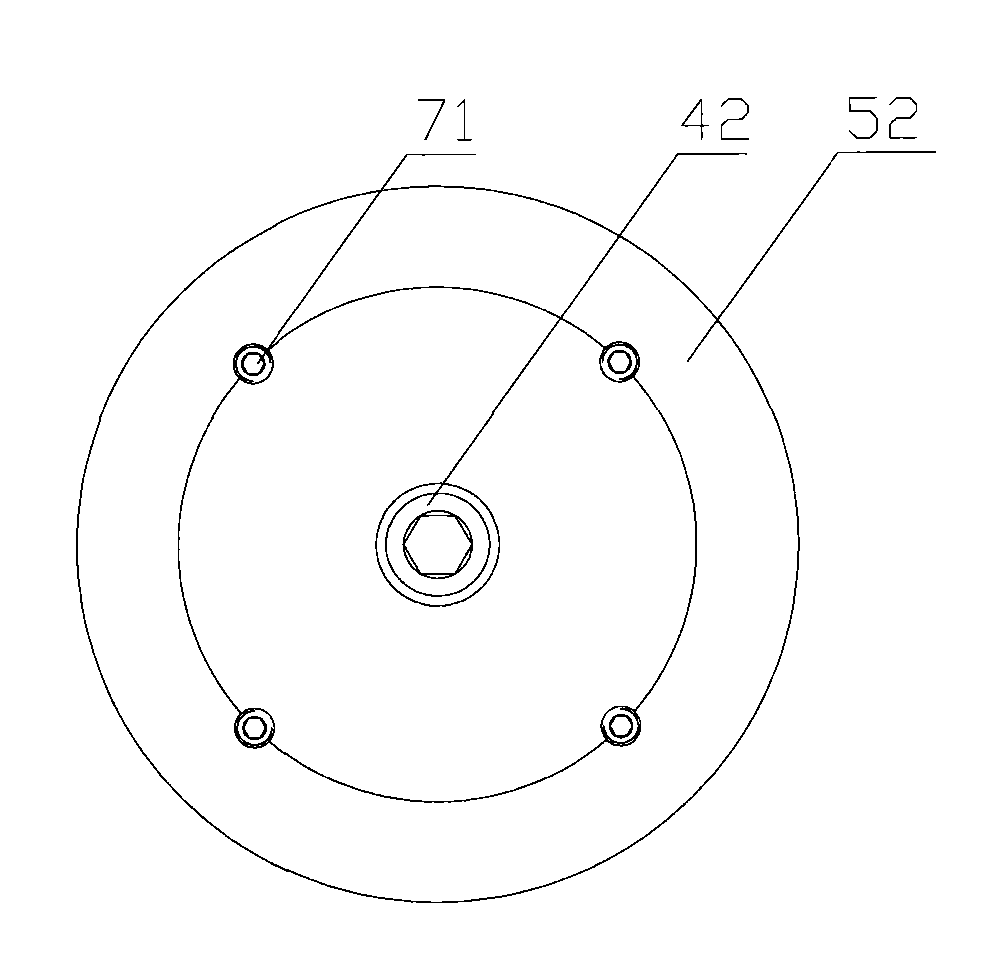

[0032] Please refer to Figure 1 to Figure 4 , figure 1 A schematic cross-sectional view of a connection fixture provided for a specific embodiment of the present invention; figure 2 A schematic front view of a connection fixture provided for a specific embodiment of the present invention; image 3 A schematic left view of the connection fixture provided for a specific embodiment of the present invention; Figure 4 It is a schematic diagram of the right side vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com