Split type bolt and manufacturing and application thereof

A split bolt and split technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of unable to bear shear stress, brittle failure, etc., and achieve the effect of simple construction, increased ductility, and easy bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

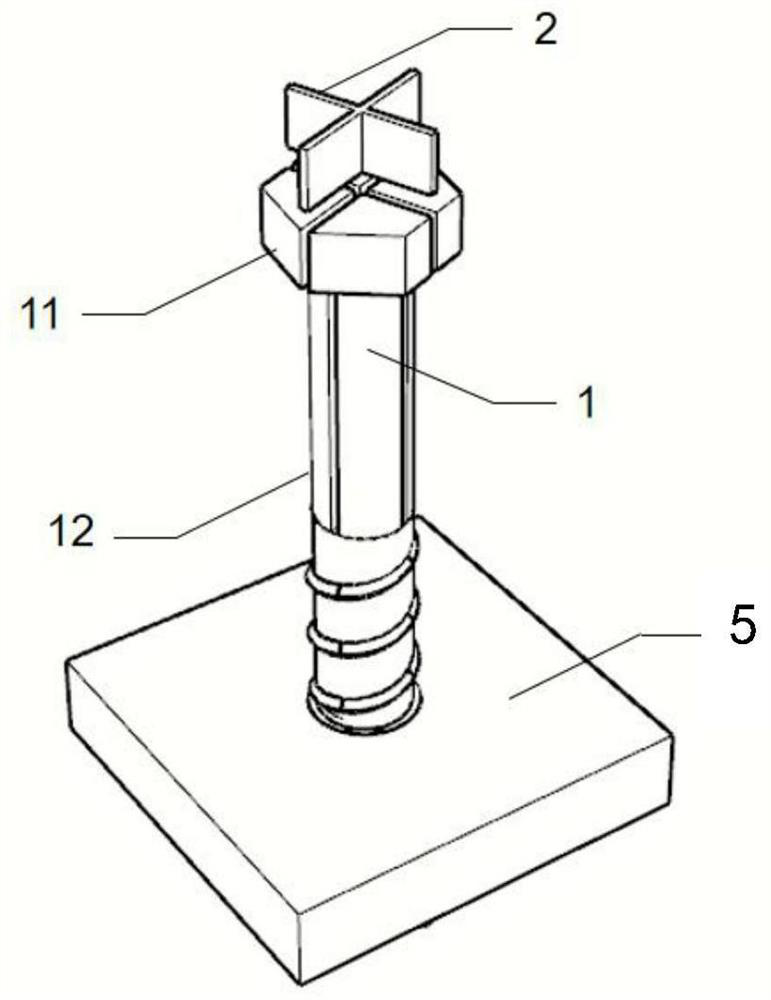

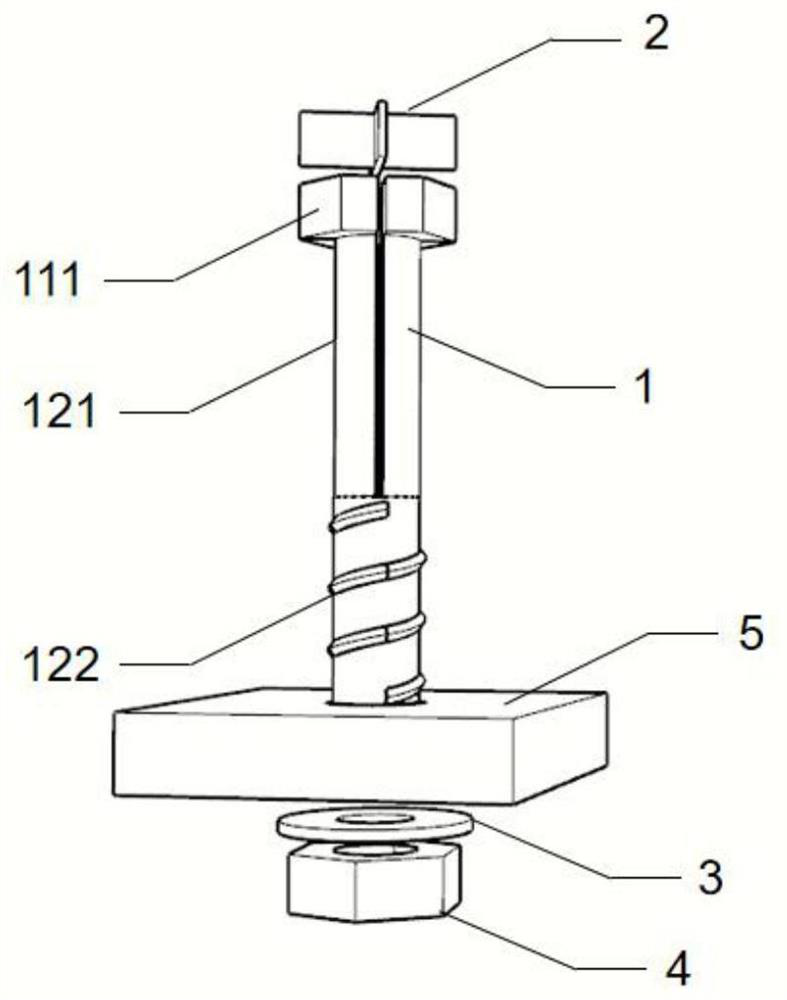

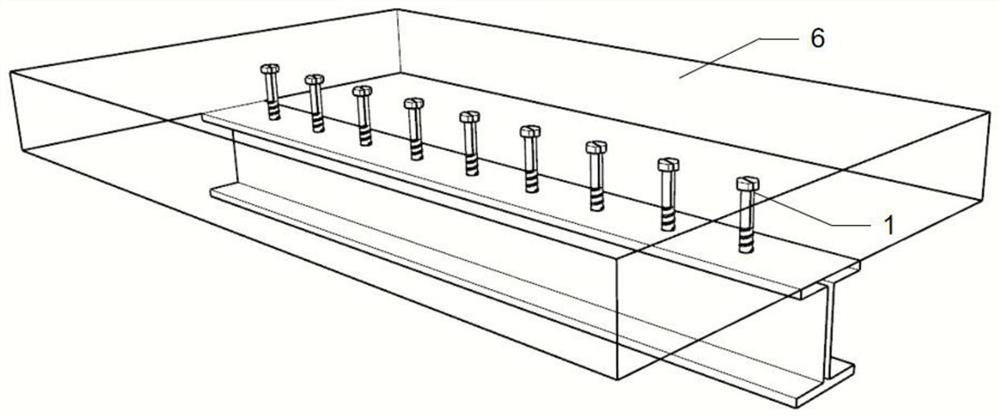

[0034] Please refer to figure 1 , the embodiment of the present application provides a split bolt 1, comprising: a bolt cap 11 and a screw rod 12, the bolt cap 11 is composed of a plurality of bolt cap split parts 111, and the screw rod 12 is composed of a screw rod base 122 and a plurality of screw rod split parts part 121, there is a gap between the adjacent bolt cap split parts 111 and the adjacent screw rod split parts 121, the gap between the bolt cap split parts 111 is filled with filling material 2, and the screw split part 121 The gap between them is not filled. In this embodiment, the filling material 2 is a steel sheet.

[0035] During application, the split bolt 1 is connected with the perforated steel plate 5 with a washer 3 and a nut 4 .

[0036] The plurality of split parts can make the split bolt 1 have good ductility, and the rigidity of each split part is small, and it is easier to bend and deform, so as to achieve the effect of high bearing capacity and good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com