Automobile glass lifter

An automotive glass and lifter technology, applied in windshields, vehicle parts, windows, etc., can solve the problems of easy wear of pulleys, unstable operation of lifters, and easy deformation of guide rails, so as to prolong the life time, reduce the The effect of product quality failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be explained in conjunction with the accompanying drawings and embodiments as follows:

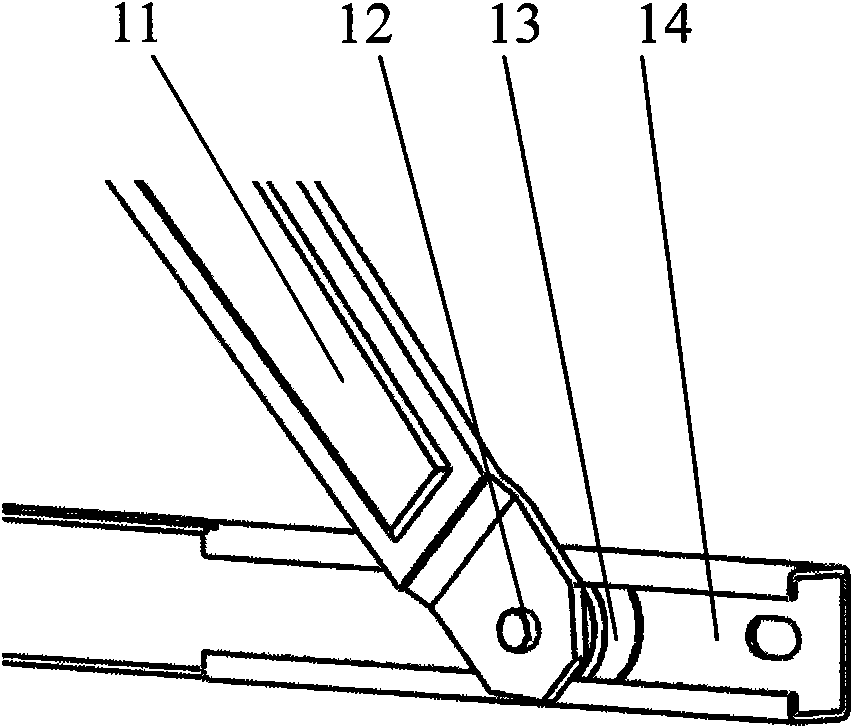

[0020] Such as Figure 4 with 5 As shown, the names of the components are as follows:

[0021] The jib 1, the rotating shaft 2, the sliding block 3, the fixed guide rail 4, the tooth plate 5, the motor 6, the movable guide rail 7, the spline shaft 8, the main arm 9, the base plate seat shaft 10, the main arm or the auxiliary arm 21, and the guide rail 22.

[0022] A glass lifter for automobiles includes a main arm 9, a jib 1, a fixed guide rail 4, a movable guide rail 7, a gear plate 5, a motor 6, a base shaft 10, a rotating shaft 2, a sliding block 3, and one end of the main arm 9 is fixed with a The tooth plate 5 driven by the motor 6, the other end is clamped in the moving rail 7 by the slider 3, one end of the jib 1 is clamped in the moving rail 7 by the slider 3, and the other end is clamped in parallel with the moving rail 7 by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com