Vacuum pipeline

A vacuum pipeline and vacuum technology, applied in the field of fluid conveying pipelines and pipelines, can solve the problems of increased cold loss of joints, large vacuum interlayer space, and short straight-line distance, etc., and achieve reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

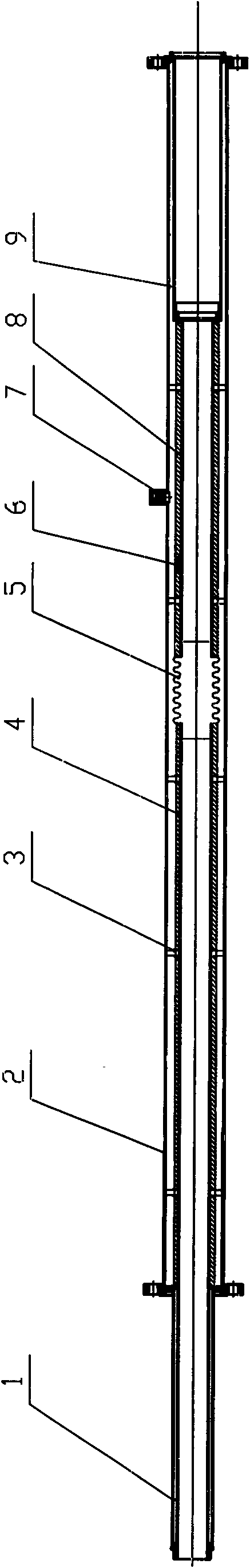

[0017] The vacuum pipeline structure of the present embodiment is as figure 1 As shown, a vacuum is drawn between the inner pipe 4 and the outer pipe 2 sheathed therein. The outer surface of the inner tube 4 is attached with a thermal insulation material 8 and an adsorbent 6 , and its part located in the outer tube 2 is supported on the inner wall of the outer tube by supporting rings 3 arranged at intervals. Since the vacuum pipeline in this embodiment is relatively long, the inner tube is composed of two sections, which are located in the middle of the outer tube and connected by a corrugated compensator, so that the thermal deformation of the inner tube can be supplemented.

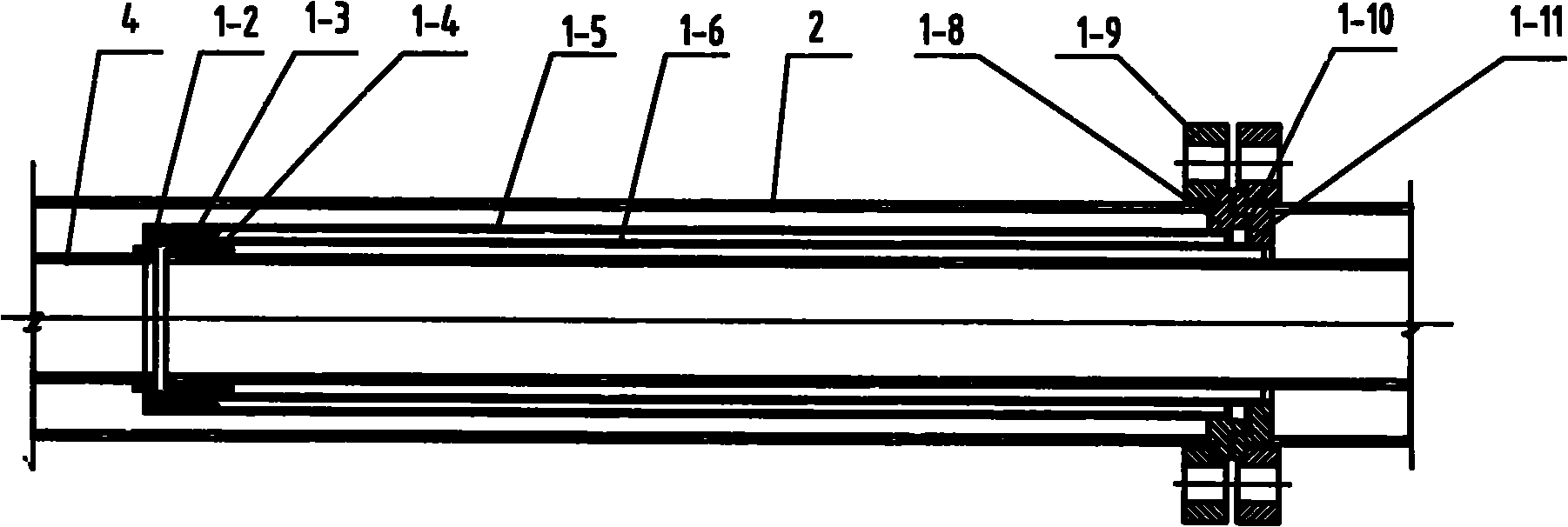

[0018] The two ends of the outer tube 2 are respectively in sealing connection with the first outer flange 1-11 and the second outer flange 1-8 (see figure 2 ). The outer edges of the first outer flange 1-11 and the second outer flange 1-8 form a seam ring that exceeds the outer diameter of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com