Self-aligning self-adaptive pinch wheel

A self-adaptive, pressure-rolling technology, applied in the direction of conveying filamentous materials, shafts and bearings, thin material handling, etc., can solve problems such as runout, gaps, affecting product quality and production efficiency, etc., to extend service life and improve products. The effect of quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

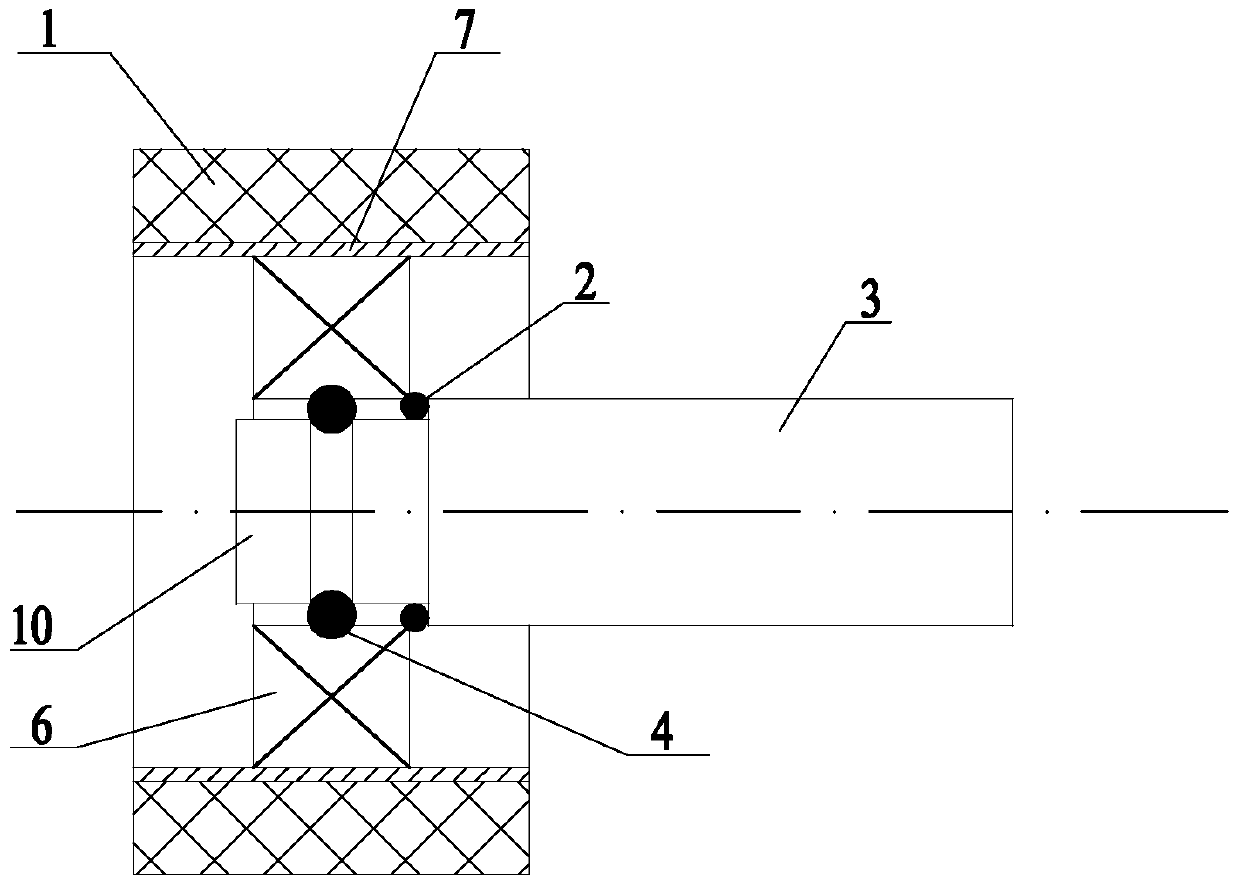

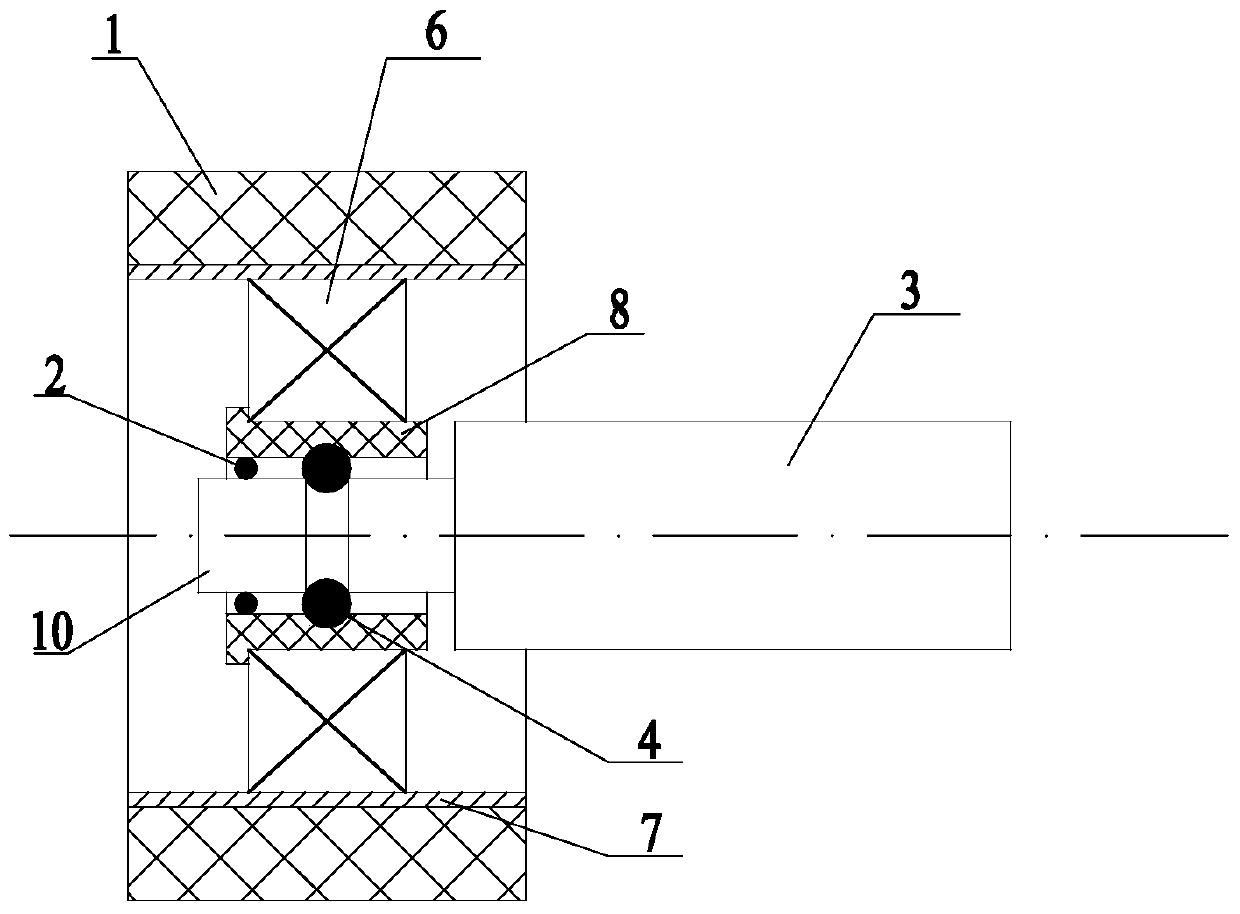

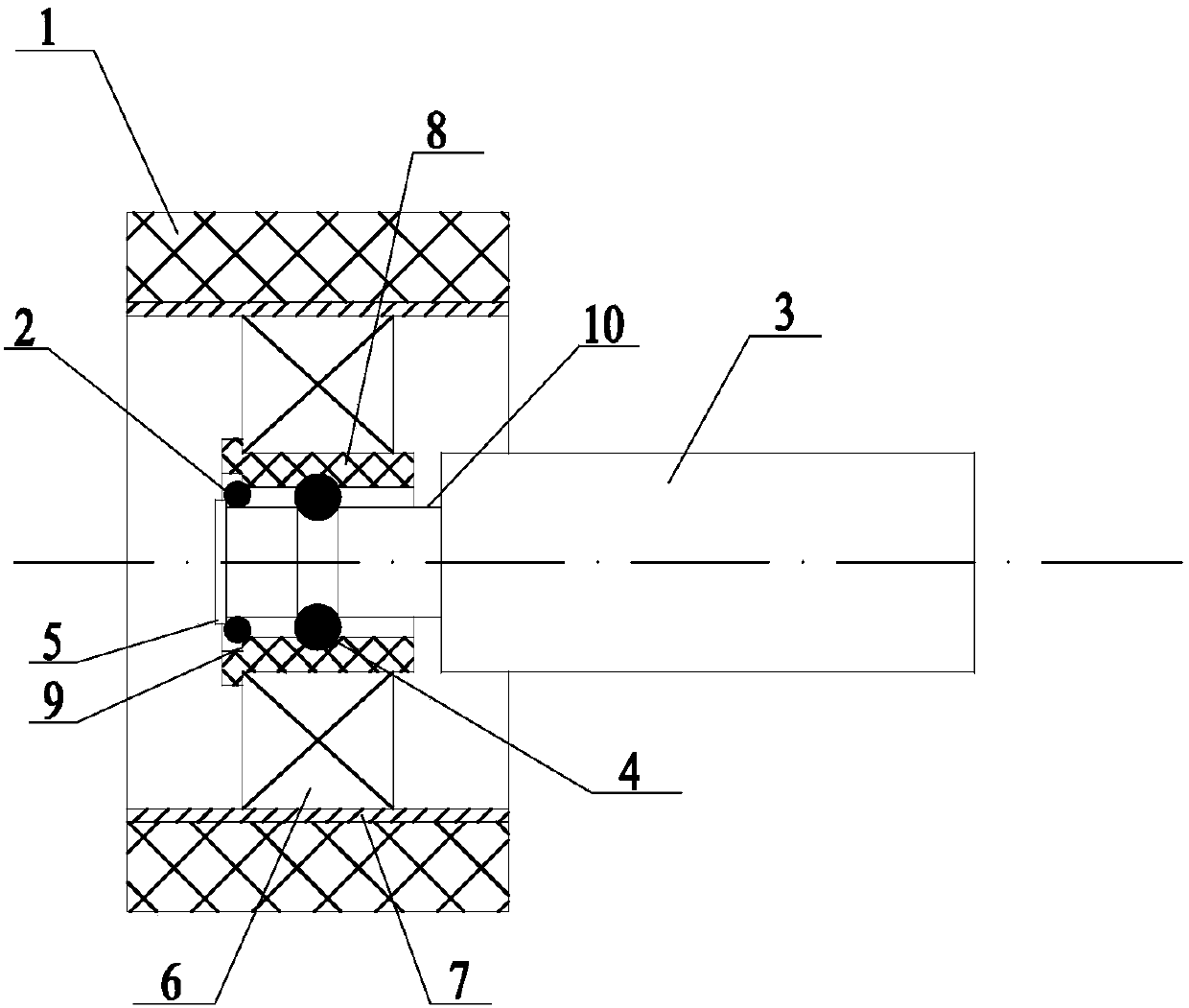

[0019] In order to obtain a smooth and constant working condition of the adaptive pinch wheel, improve product quality and production efficiency, and prolong the service life of the adaptive pinch wheel, the present invention includes a pinch wheel shaft 3 and a coaxial Distributed support shaft 10; the main support 4 is sleeved on the support shaft 10; the elastic auxiliary support 2 is also sleeved on the support shaft 10; Positive pressure wheel outer ring 1.

[0020] Specifically, a support shaft 10 is provided at the front end of the pinch shaft 3, and the outer diameter of the support shaft 10 is smaller than the outer diameter of the rear end of the pinch shaft 3. The elastic auxiliary support 2 and the main support 4 are both sleeved on the support shaft 10 of the pinch shaft 3. superior. The pressure wheel outer ring 1 is installed on the support sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com