Synchronous Accuracy Adjustment Method of Crankshaft Double-point Press

A technology of synchronous accuracy and adjustment method, which is applied to the driving device of forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc. Affect the synchronization accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

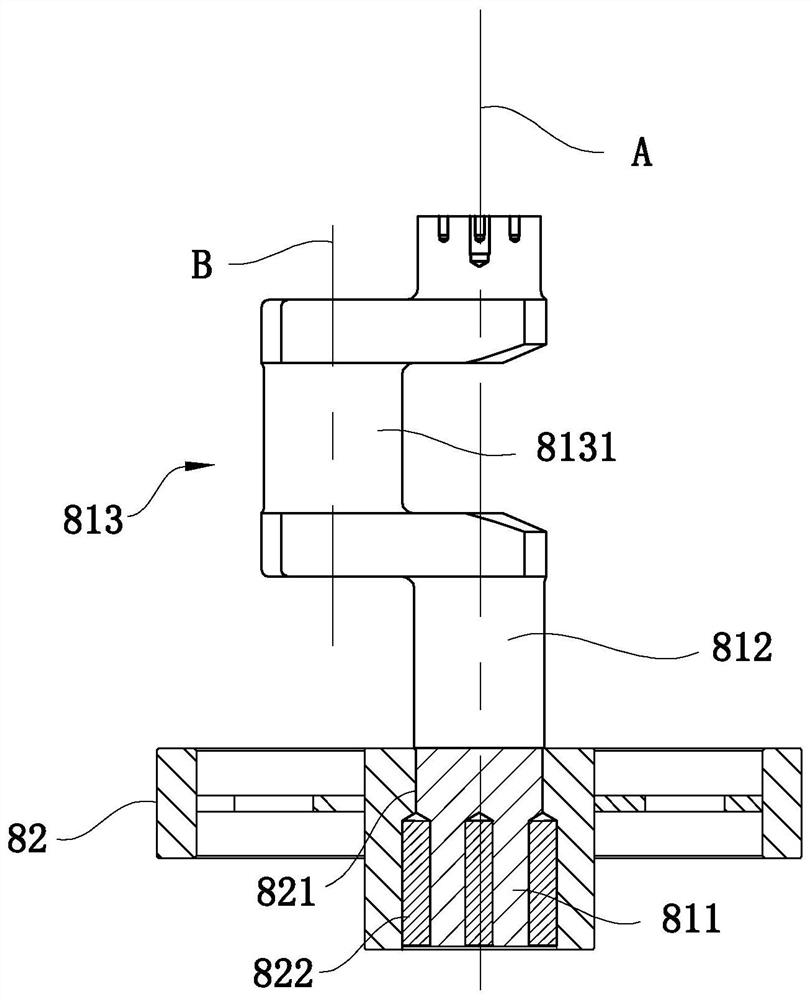

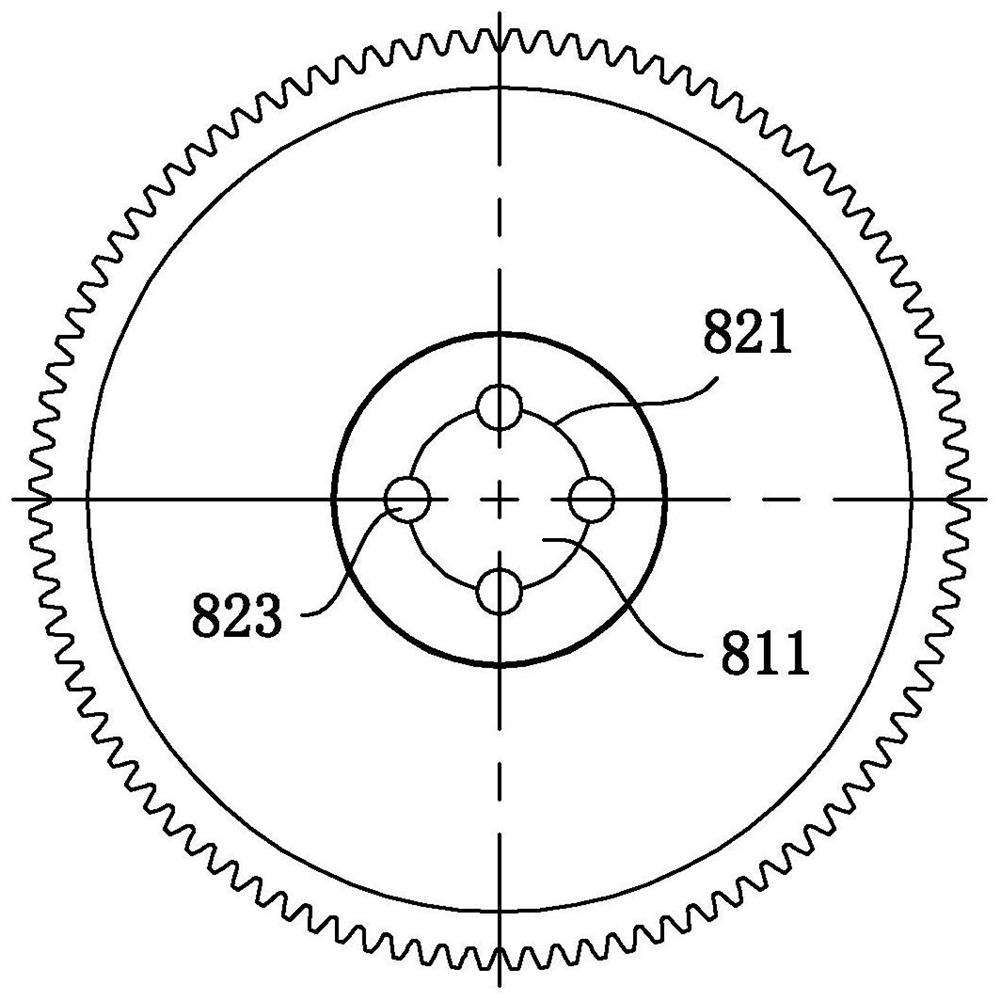

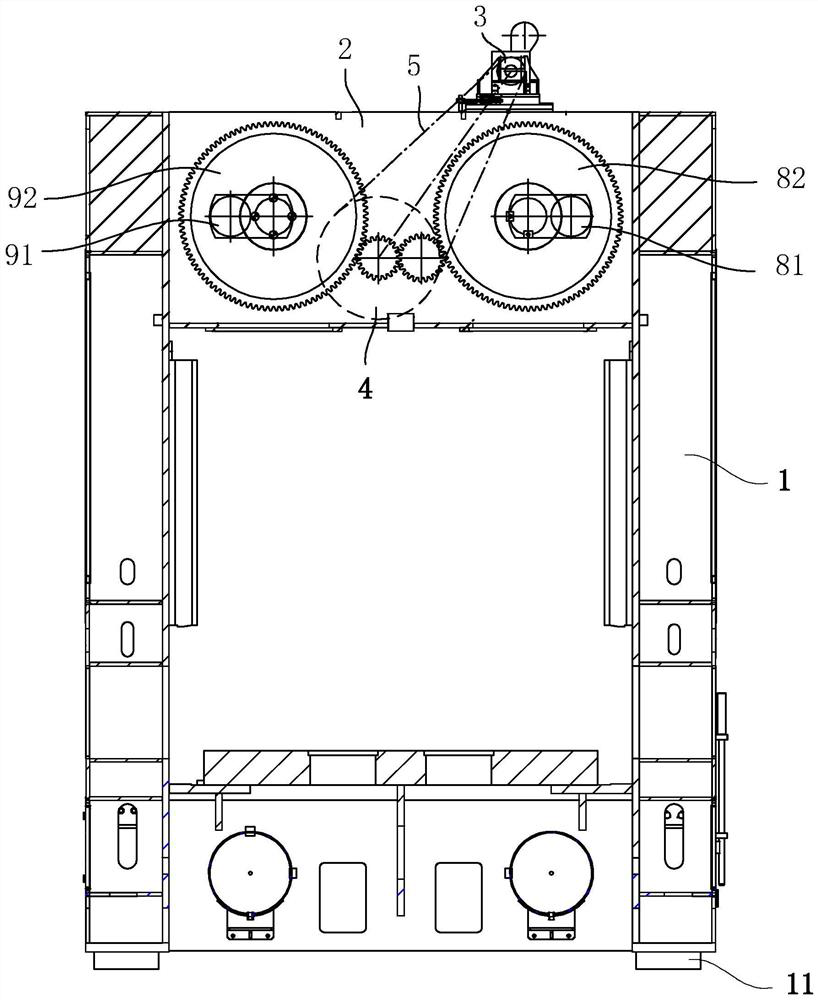

[0074] common reference figure 1 and figure 2 , a crankshaft type two-point press transmission positioning structure, the positioning connection mode between the first crankshaft 81 and the first driving gear 82 and the positioning connection mode between the second crankshaft 91 and the second driving gear 92, this embodiment Take the first crankshaft 81 and the first driving gear 82 as examples for structural illustration.

[0075] The transmission positioning structure includes a connecting end 811 located at the end of the first crankshaft 81. The first drive gear 82 is provided with a mounting hole 821 for the connecting end 811 to be clamped. The contact surface between the connecting end 811 and the mounting hole 821 is multi-point welded. Implement pre-connect positioning. Between the connecting end 811 and the inner wall of the mounting hole 821 there are four positioning holes 823 uniformly distributed in the circumferential direction, and the positioning pins 822...

Embodiment 2

[0082] A method for adjusting the synchronous precision of a crankshaft type double-point press, which is aimed at adjusting the synchronous precision of the transmission mechanism in the crankshaft type double-point press according to Embodiment 1. Specifically include the following steps:

[0083] Step 1, adjust the levelness of the upper end surface of the beam 2 so that the upper end surface of the beam 2 is in a horizontal state. Adjustment operation refer to Figure 5 and Figure 6 , set up a ruler 30 on the upper end surface of the beam 2, and move the ruler 30 so that the ruler 30 is above the first crank 813 and the second crank 912. Furthermore, the width of the square ruler 30 is equal to the length of the first connecting rod crank 8131 or the second connecting rod crank 9121 , so that when the straight ruler 30 is projected forward onto the first bell crank 813 and the second bell bell 912 , Completely cover the first connecting rod curved neck 8131 and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com