Safety electrically heating bag with exhaust valve shelter

A shielding and exhaust valve technology, applied in the field of safe electric heating bags, can solve the problems of scalding users, scalding, gas or liquid overflow, etc., and achieves the effects of convenient opening and closing, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

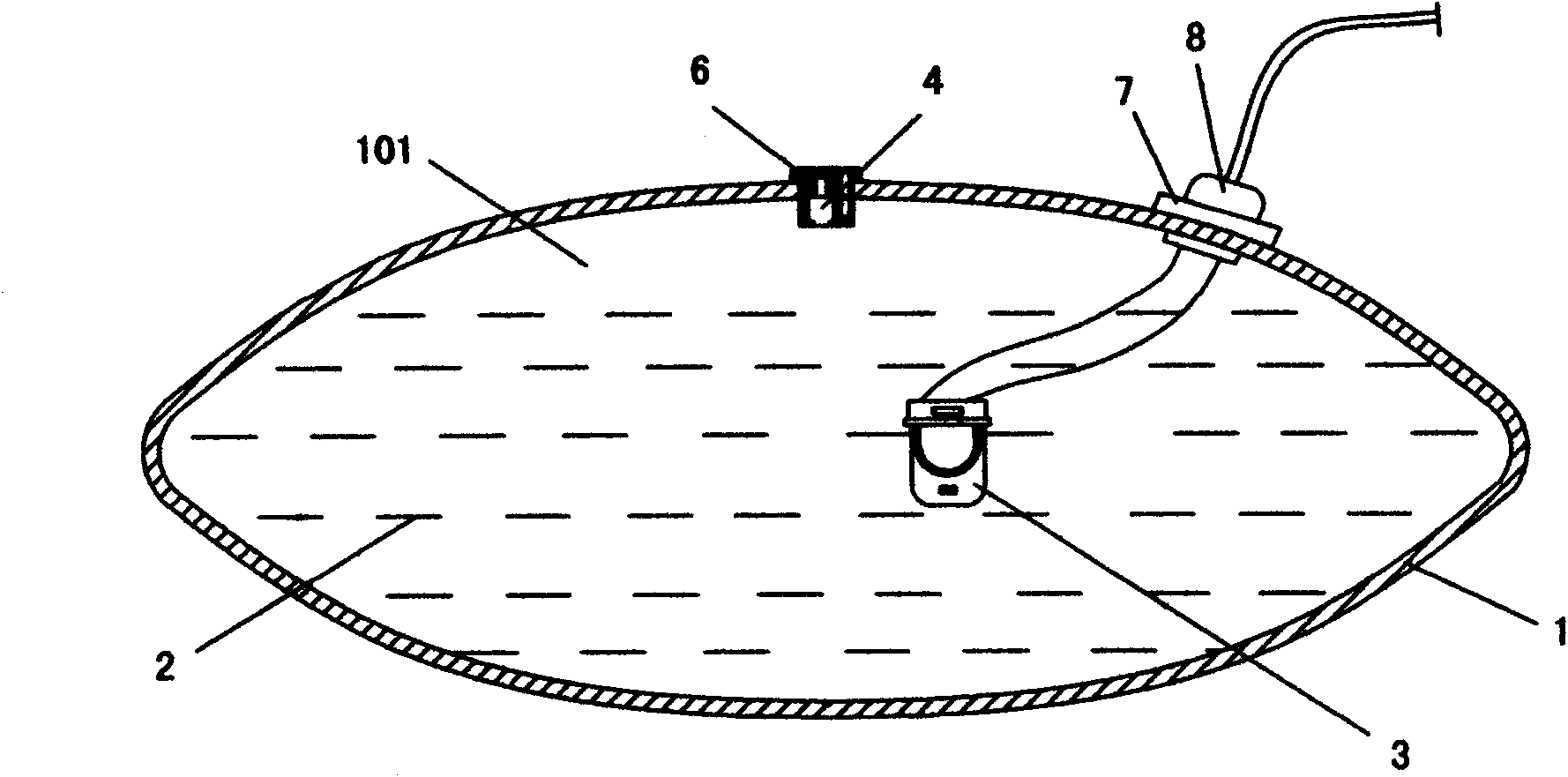

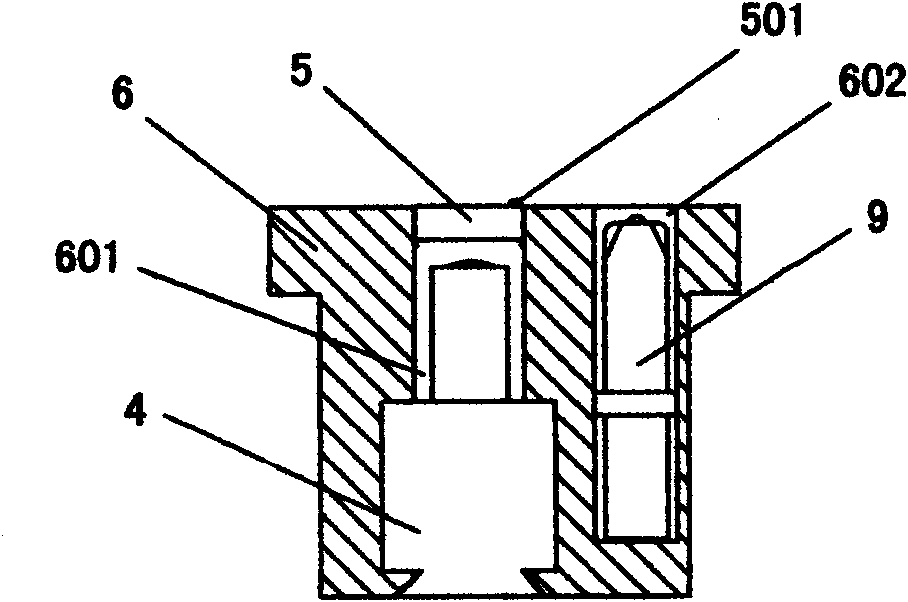

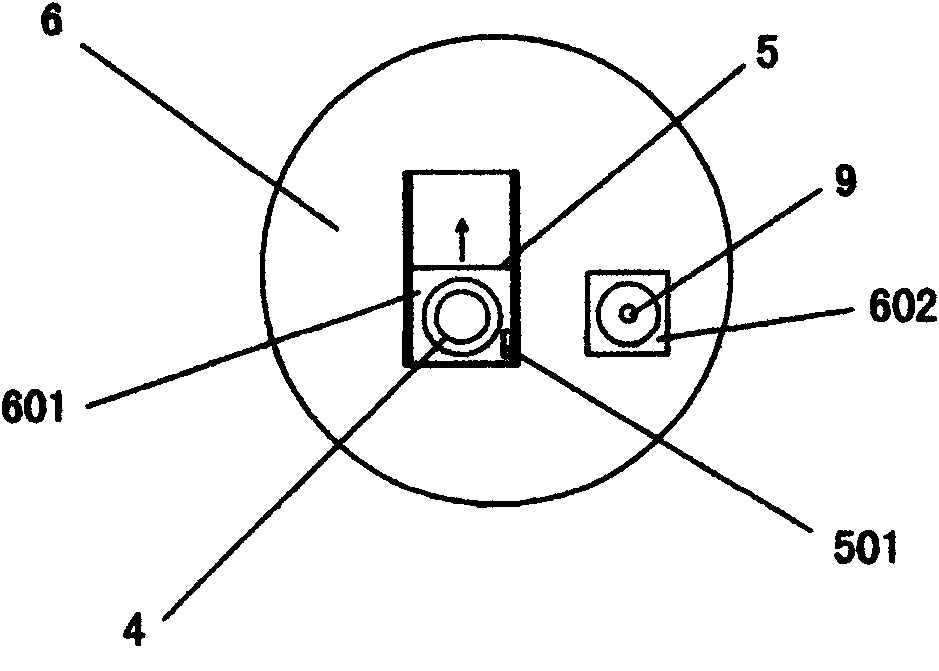

[0022] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a safety type electric heating heating bag with an exhaust valve shield includes a bag body 1 with a bag cavity 101, a liquid 2 and its electric heating body 3 are arranged in the bag cavity 101, and the wall of the bag body 1 The exhaust valve 4 that can discharge the gas in the bag cavity 101 is installed on the part, and the barrier 5 that can block the exhaust valve 4 by sliding is also installed on the wall of the bag body 1 . Its specific sliding setting method is that the wall of the bag body 1 is also provided with an exhaust valve mounting seat 6, and the exhaust valve mounting seat 6 has a valve body accommodating groove 601 and a valve stem accommodating groove 602, and the valve stem accommodates The exhaust rod tool 9 that can open the exhaust valve 4 to exhaust is placed in the groove 602. The exhaust valve 4 is fixed on the valve body accommodating groove 601 and extends into the bag cavity 10...

Embodiment 2

[0024] Embodiment 2: as Figure 4 As shown, its implementation is similar to that of Example 1, the difference is that the barrier 5 is a transparent arc-shaped sliding cover, and the barrier 5 is installed on the exhaust valve mounting seat through the rotating shaft 10, so that the barrier 5 is arranged on the shaft The rotating slide is installed on the surface of the exhaust valve mounting seat 6 and can cover the valve body accommodating groove 601 . Its working principle is similar to Embodiment 1, and will not be described in detail here.

Embodiment 3

[0025] Embodiment 3: as Figure 5 and Image 6 As shown, its implementation is similar to that of Example 1, the difference is that an electric socket 7 is fixed on the wall of the bag body 1, and an electric plug groove 701 and a valve body accommodating groove 702 are arranged on the electric socket 7, and the exhaust The valve 4 is fixed on the valve body accommodating groove 702 and extends into the bag cavity 101. The electric socket 7 is equipped with a shield 5 that can block the upper opening of the electric plug groove 701 or the valve body accommodating groove 702 by sliding. Wherein, the barrier 5 is installed on the electric plug groove 701 and the upper opening of the valve body accommodating groove 702 on the electric socket 7 in a sliding manner of a horizontal slide rail, so that the electric plug groove 701 needs to be plugged into the power plug 8 before the electric plug groove 701 is energized. The object 5 moves to the upper opening of the valve body acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com