Liquid level sensor with rotatable type electrode

A liquid level sensor, rotary technology, applied in the direction of the liquid level indicator for physical variable measurement, etc., can solve the problems of inconvenient installation and short service life of the liquid level sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

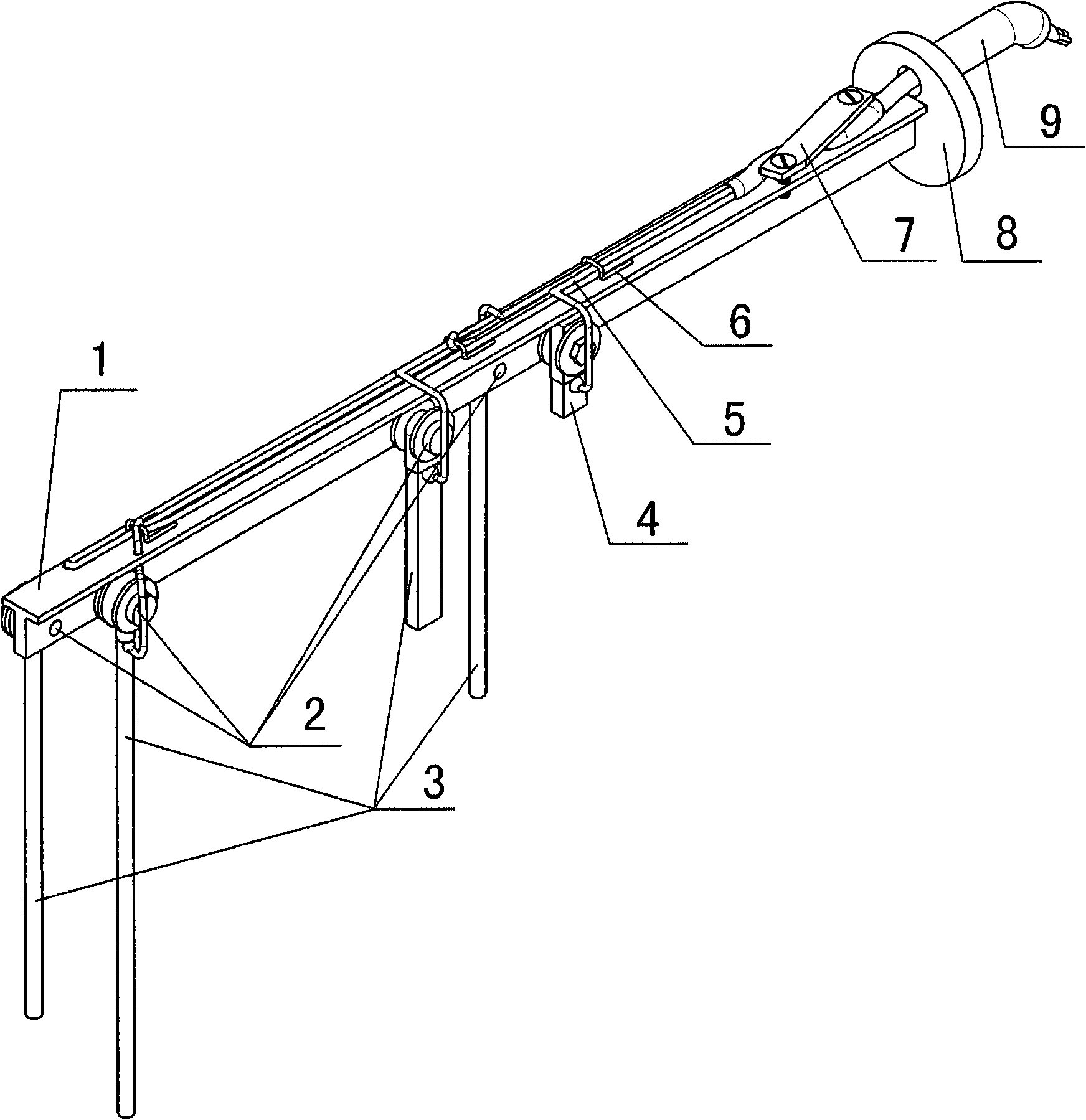

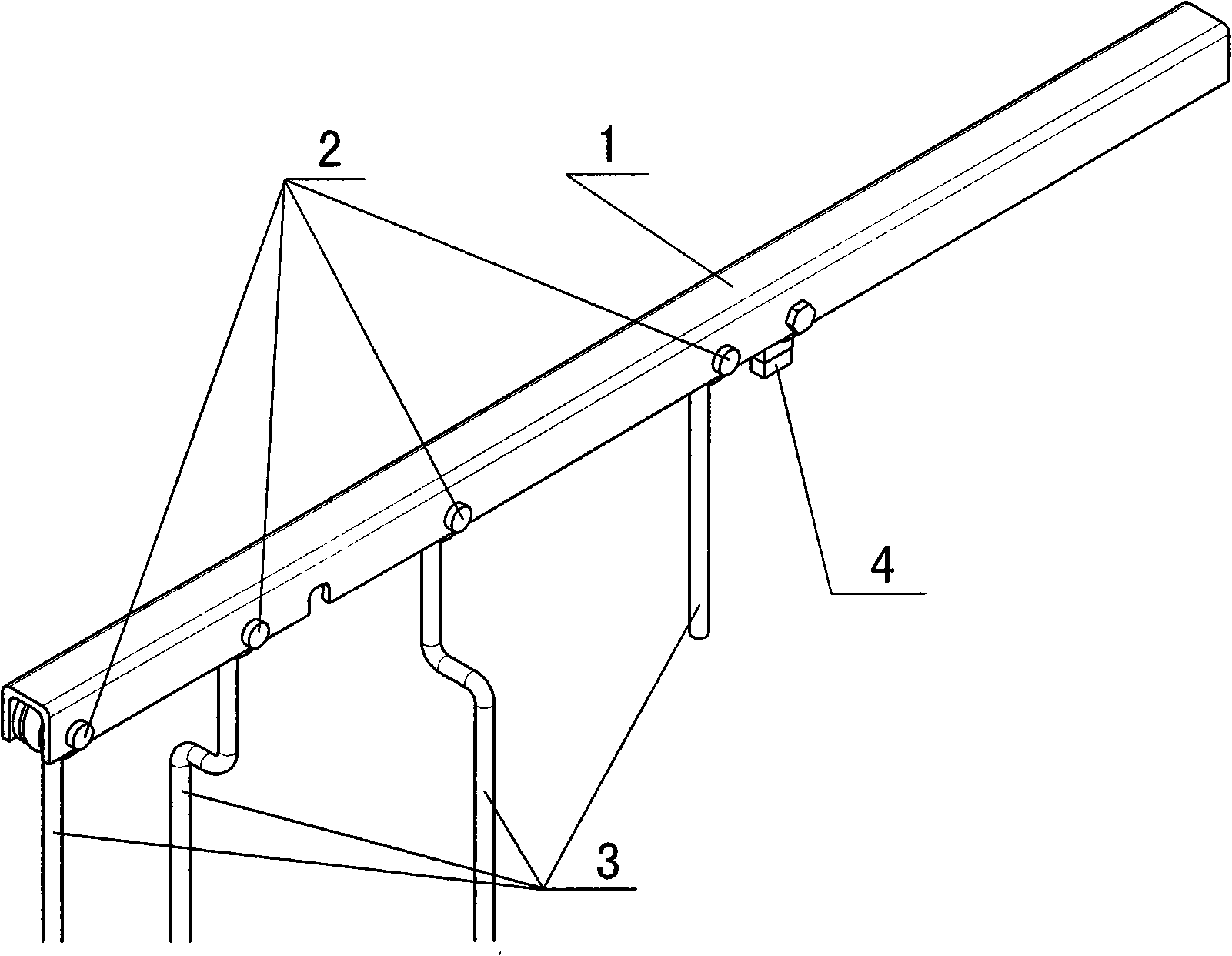

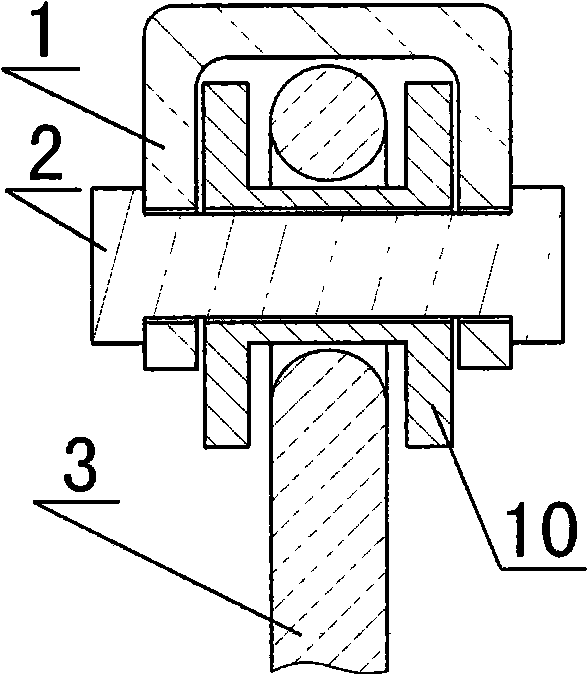

[0035] exist figure 1 In the shown first embodiment, the cross-section of the beam 1 is T-shaped, and five holes are arranged on its vertical plate. figure 1 In the four holes on the left side of the center, four short shafts 2 are installed with interference connection, and four rotatable electrodes 3 are installed on the four short shafts. In the other hole, a bolt connection is installed. The fixed electrode 4, the electrode lead 5 passes through the electrode lead constraining structure 6, and then the pressure plate 7 is pressed on the beam at the end of the beam close to the circular metal mounting piece 8, between the beam 1 and the circular metal mounting piece 8 Directly welded together, there is a hole on the circular metal mounting piece 8, and an outlet pipe 9 is welded at the hole position, and the electrode lead 5 passes through the pressure plate, and then passes through the hole on the circular metal mounting piece and the outlet pipe to lead out .

[0036] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com