Control method for water boiling of electric kettle

A control method and technology for electric kettles, which are applied to water boiling appliances and temperature control using electric methods, and can solve problems such as waste of electric energy, dry heating, and temperature rise of electric heating elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

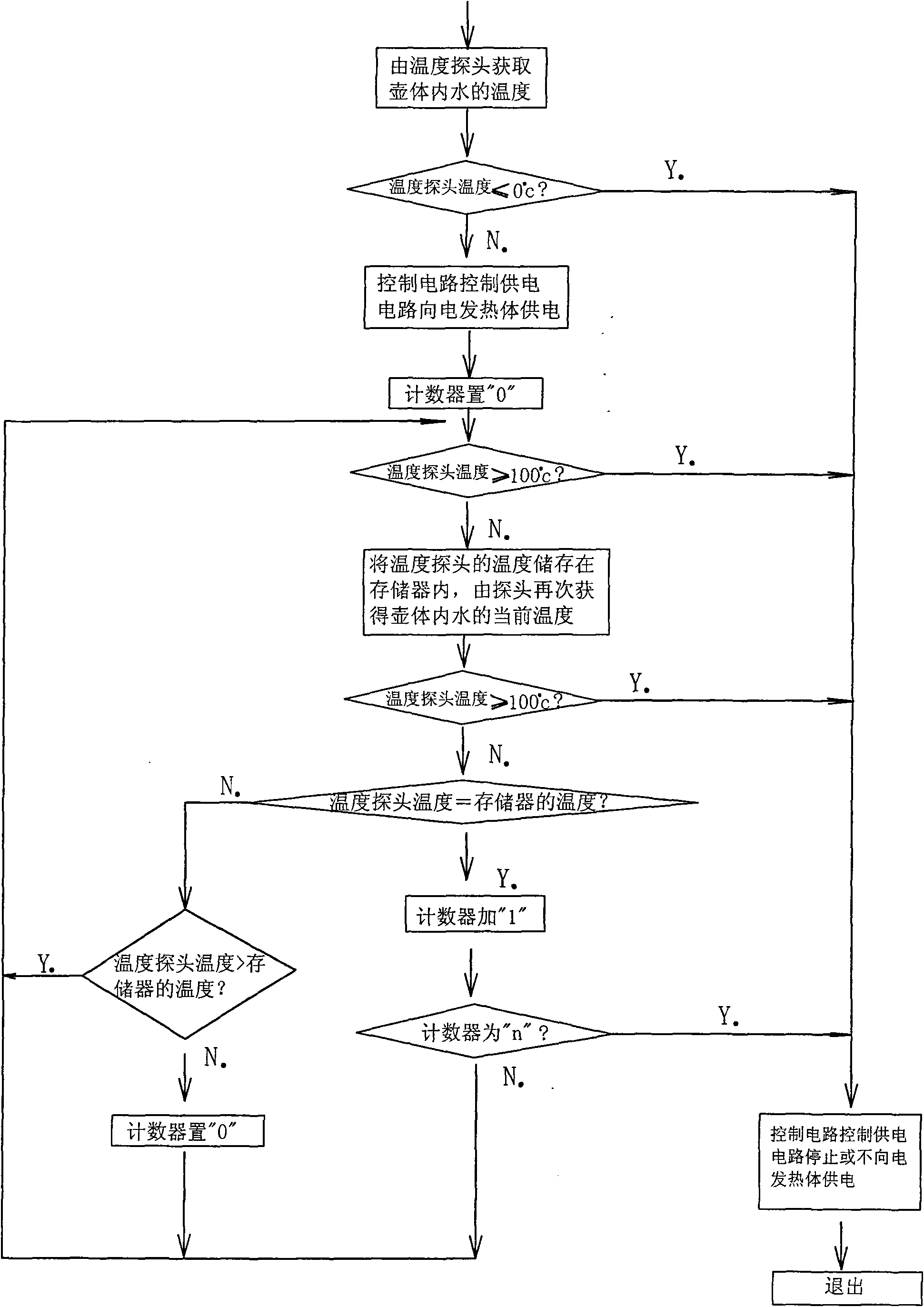

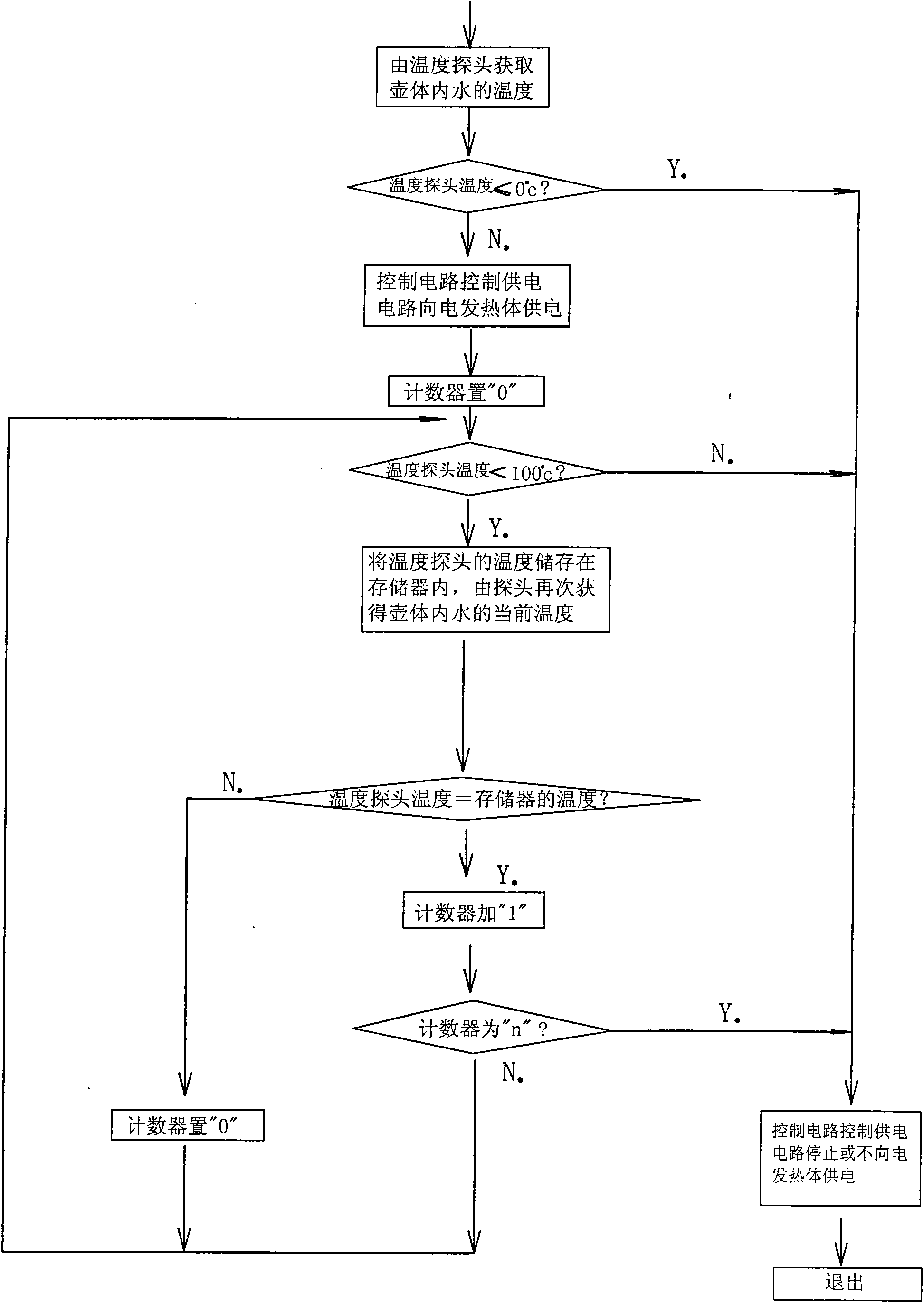

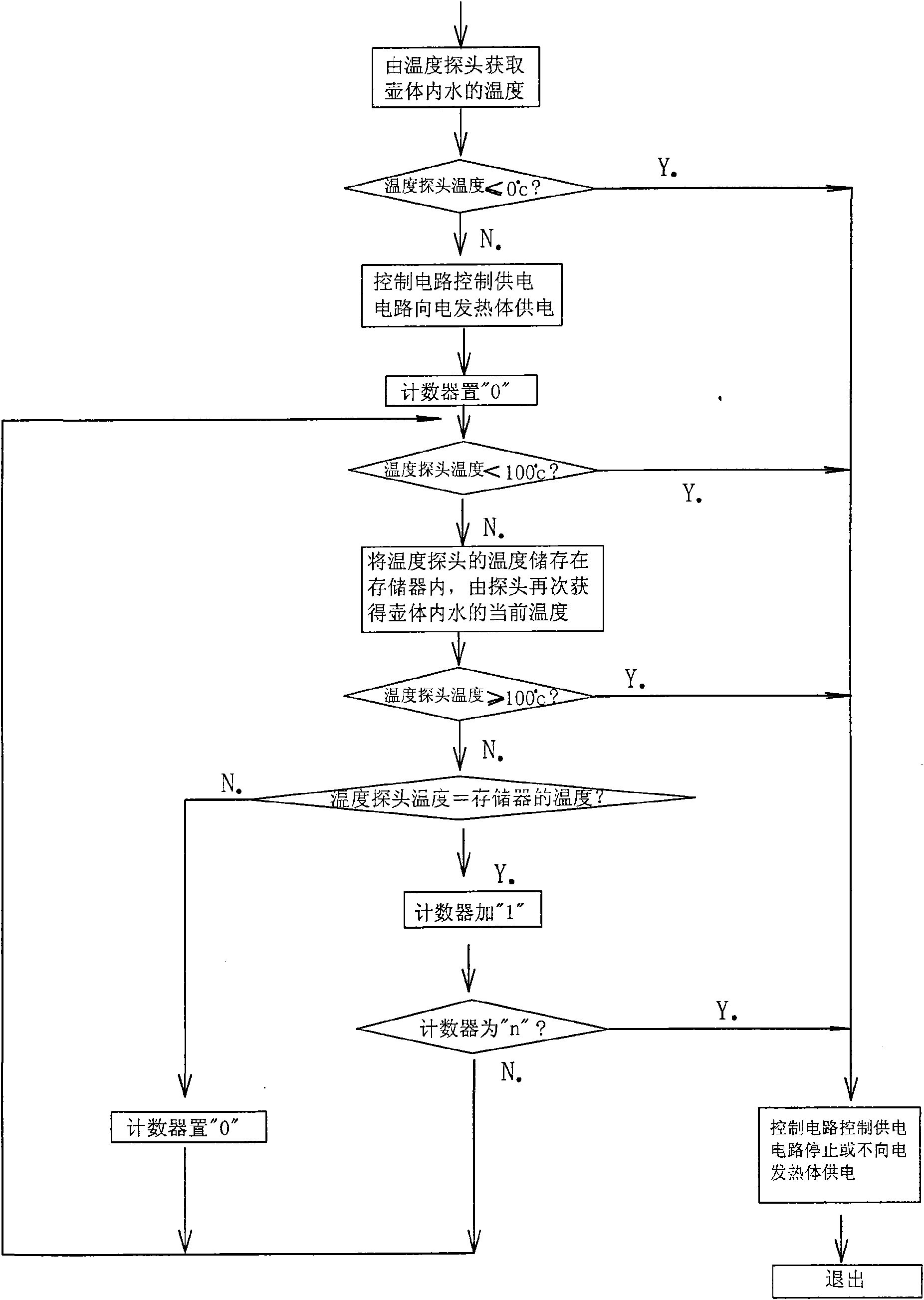

[0041] refer to figure 1 , the control method of this specific electric kettle boiling water adopts the following steps:

[0042] (1) The current temperature of the water in the pot is detected by the temperature probe of the control circuit, and the current temperature of the temperature probe is compared with 0°C. When the current temperature of the temperature probe is ≤0°C, the control circuit controls the power supply circuit not to generate heat When the current temperature of the temperature probe is > 0°C, the control circuit controls the power supply circuit to supply power to the electric heating element, the electric heating element emits heat, and the counter is set to "0";

[0043] (2) Compare the current temperature of the temperature probe with 100°C. When the current temperature of the temperature probe is ≥100°C, the control circuit cuts off the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com