Triad structure light electric vehicle main body structure

An electric vehicle and main structure technology, which is applied to the superstructure, substructure, and subassembly of the superstructure, etc., can solve the problems of reduced power performance, excessive weight of electric vehicles, and small development investment, and achieves high safety and reliability. Excellent protection, enhanced safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5a , Figure 5b , Figure 5c Constitute a specific embodiment of the present invention.

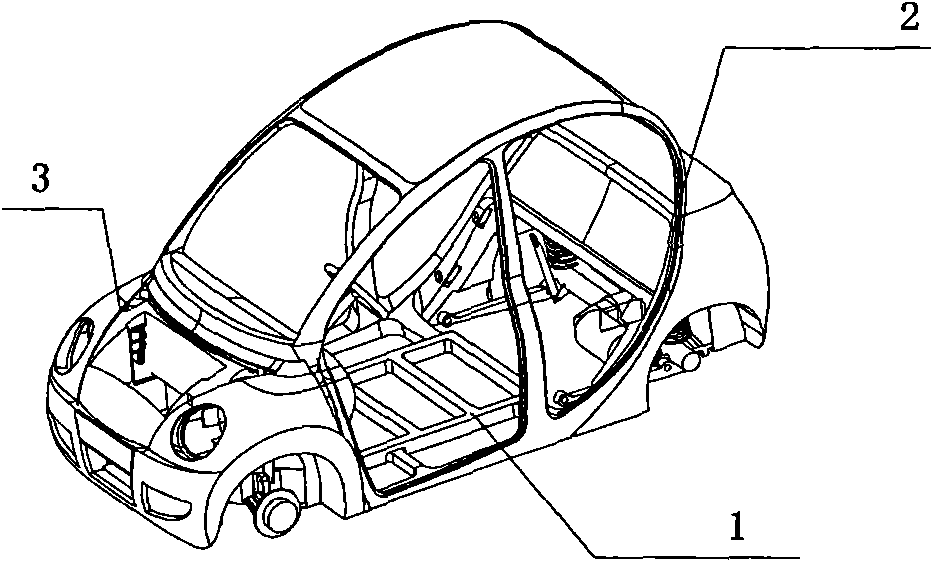

[0034] see figure 1 , the present embodiment includes three independent structural units, the first structural unit constitutes the chassis frame 1, the second structural unit constitutes the cage box 2, and the third structural unit constitutes the cover 3; the chassis frame 1 and the The cage-shaped box body 2 is fixedly connected to form a combined load-bearing frame, and a fixed cover 3 is installed on the basis of the combined load-bearing frame, and the cover 3 is fixedly installed on the front end, rear end or front end of the combined load-bearing frame And the rear end, 3 pairs of covering parts constitute the wrapping structure of the combined vehicle frame, and form the external modeling structure of the main body structure of the automobile.

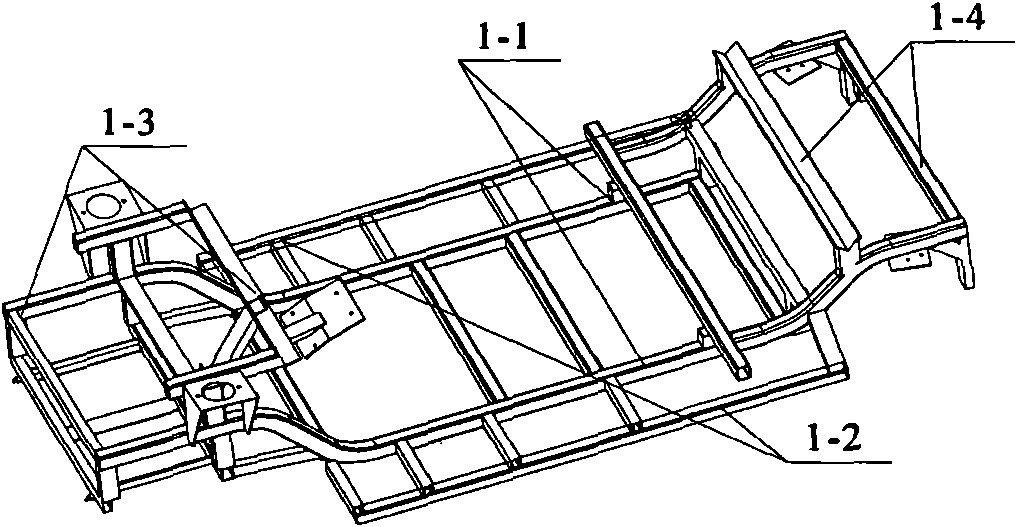

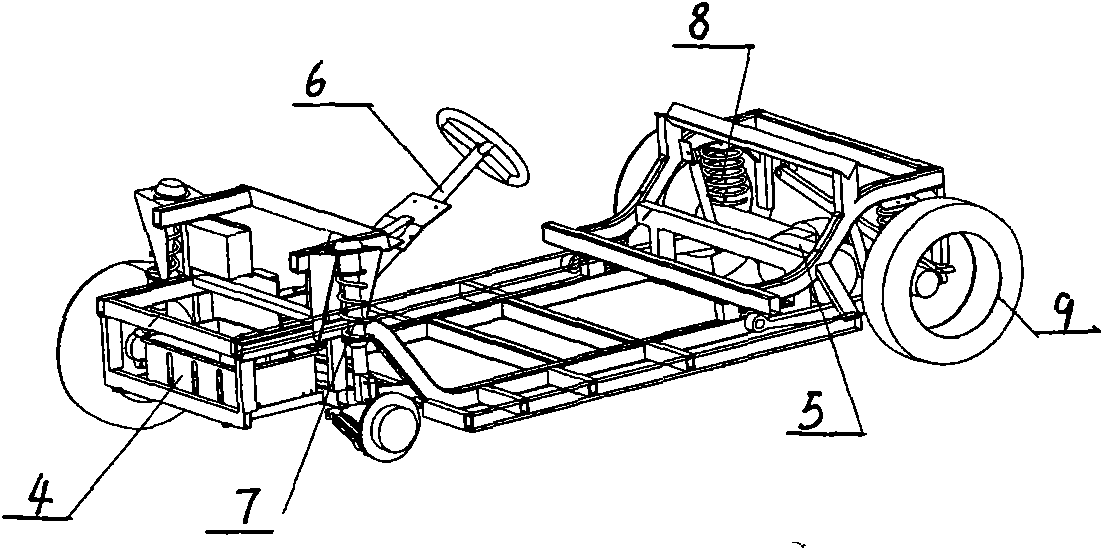

[0035] refer to figure 2 , the chassis frame 1 of the present ...

specific Embodiment 2

[0045] refer to Figure 4 The main difference between this embodiment and the previous embodiment is that part or all of the covering parts are composed of some surface structural parts, the structural parts are fixedly installed on the combined vehicle frame, and there is also a connection relationship between the covering parts.

specific Embodiment

[0047] The characteristics of other specific embodiments of the present invention are:

[0048] Part of the cover 3 can be adopted to be composed of an integral volume block, or a combination that is divided into a plurality of volume blocks 3-4 and connected to each other (divided according to the volume characteristics of the cover part); the volume block is a surface band The shell, the solid body filled with foaming light material inside, the cover part 3 is fixed on the chassis frame 1 and / or the cage box body 2 .

[0049] Also can be that part cover 3 is made of integral curved surface block, or is formed by being divided into a plurality of curved surface blocks 3-5 and the combination that is connected with each other (divided according to the characteristics of curved surface block); Described curved surface block is a band thickness and The structural part of the rib, the cover part 3 is fixed on the chassis frame 1 and / or the cage box body 2 .

[0050] All the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com