Rolling piston compressor for improving lubricating performance of slip sheet

A rolling piston type, lubricating performance technology, applied in the direction of rotary piston type machinery, rotary piston type pump, rotary piston type/oscillating piston type pump parts, etc. , The pressure difference between the compression chamber and the suction chamber of the rolling piston compressor is large, and the effect of improving the sliding conditions, increasing the sliding contact area and high reliability is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

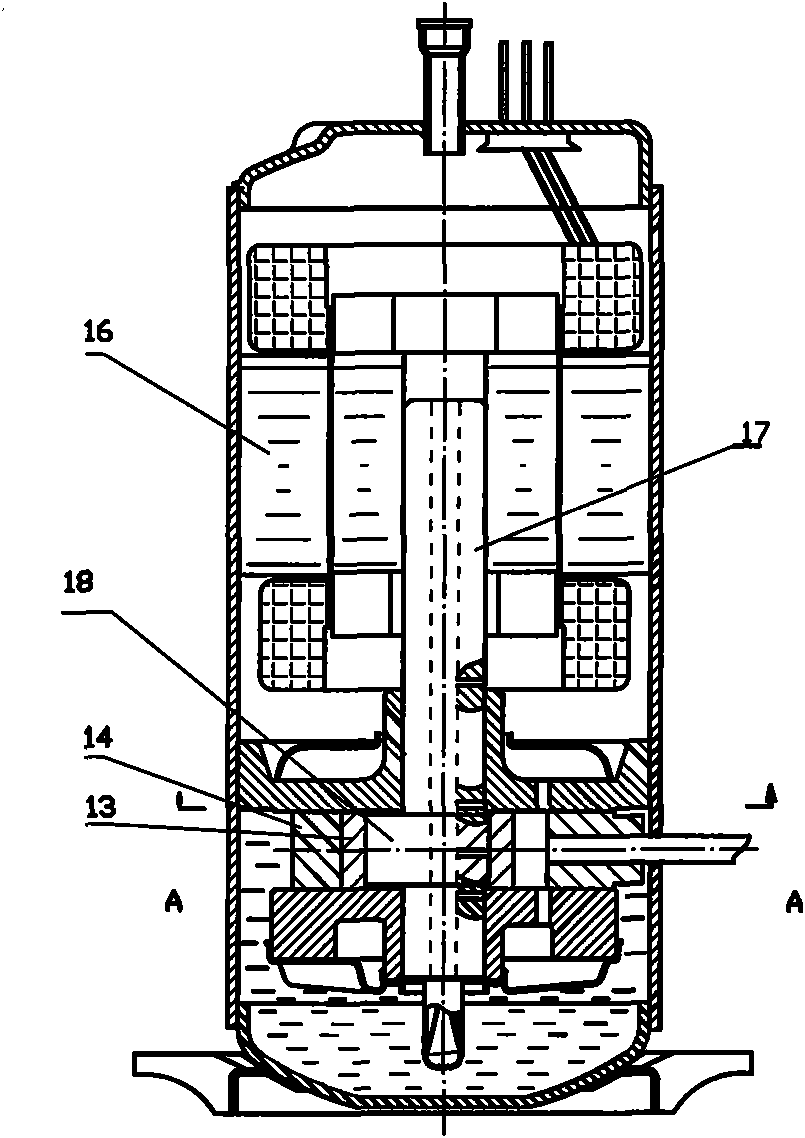

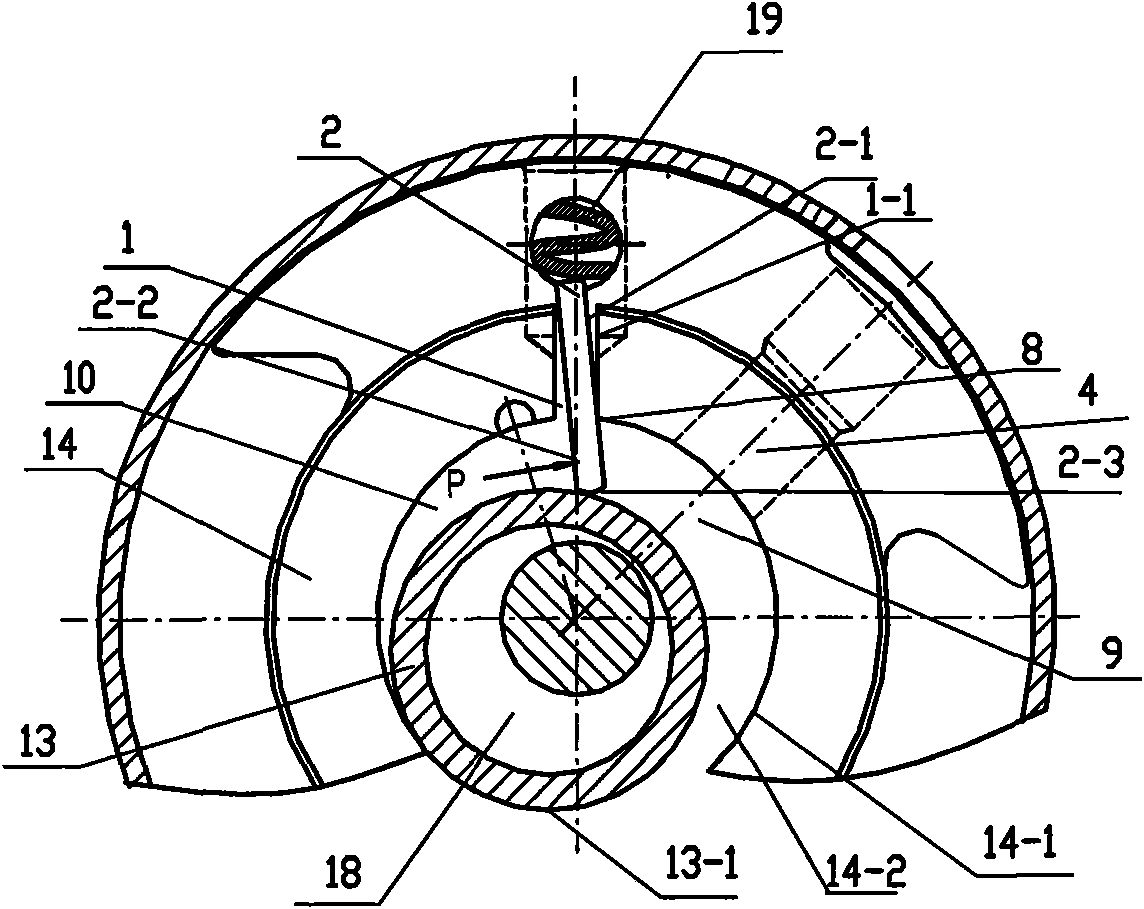

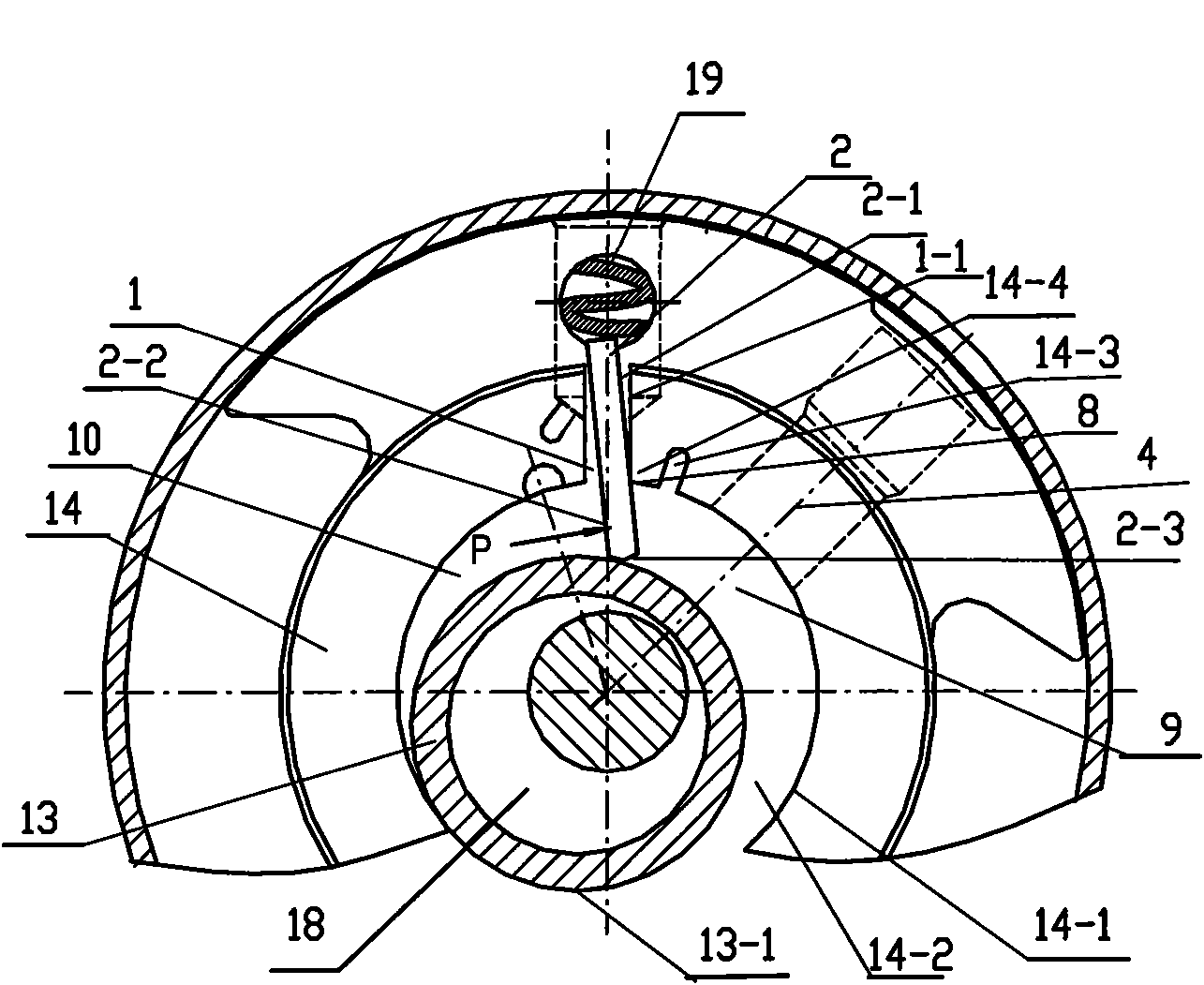

[0030] Such as figure 1 , figure 2 Shown: the existing a kind of rolling piston type compressor, the eccentric part (18) outer peripheral surface of rotating crankshaft (17) driven by motor (16) is equipped with freely rotating rolling piston (13) in cylinder hole (14-2 ) rotates eccentrically, relying on the spring (19) and the back pressure of the gas to make the arc surface (2-3) of the sliding vane (2-3) tightly pressed on the outer cylindrical surface (13-1) of the rolling piston (13), and the cylinder hole (14 -2) Divided into a suction chamber (9) and a compression chamber (10). The rotation of the crankshaft 17 drives the rolling piston 13 to rotate, and at the same time pushes the slide (2) to reciprocate in the slide groove (1) of the cylinder, and repeatedly inhales, compresses, and exhausts in the cylinder bore (14-2). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com