Scroll type fluid equipment

A fluid equipment and scroll-type technology, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, rotary piston pumps, etc., can solve the problems of reduced durability, improve durability, and suppress loosening. Loudness, the effect of suppressing the generation of abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail. In addition, the scroll type fluid device of the present invention can be used in either a compressor or an expander, and here, an example of a compressor will be described.

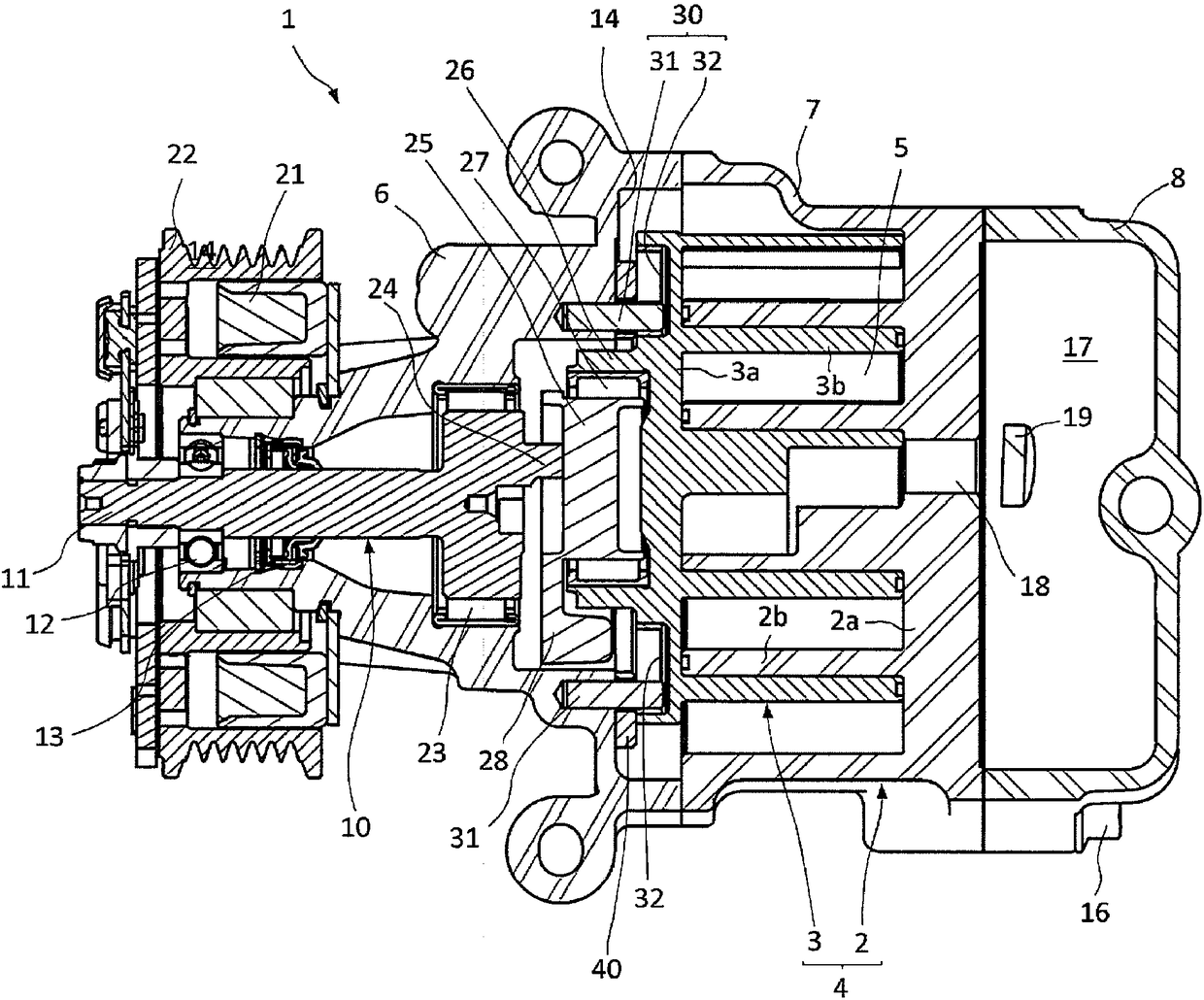

[0038] according to Figure 1 ~ Figure 4 , the first embodiment of the present invention will be described.

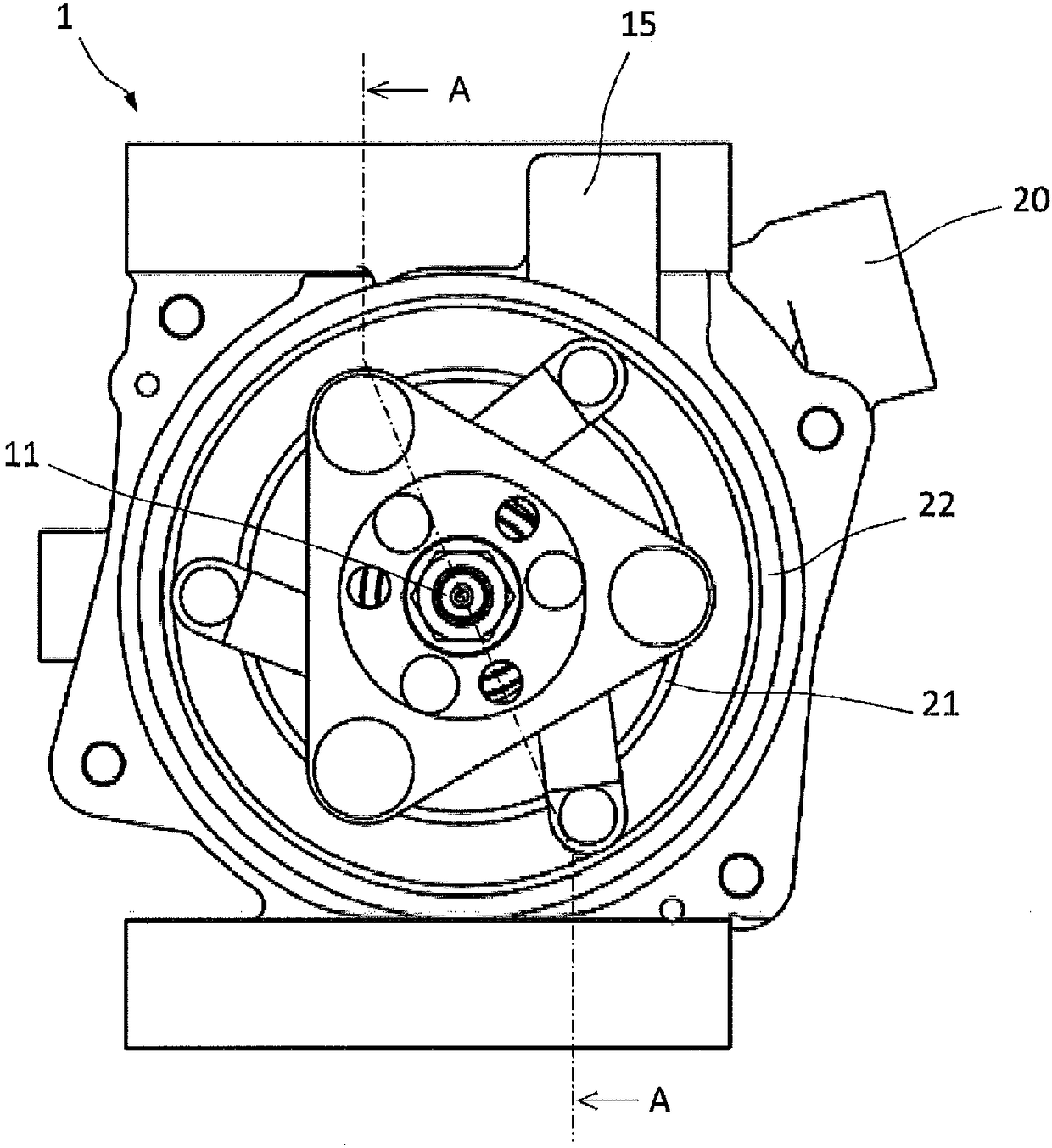

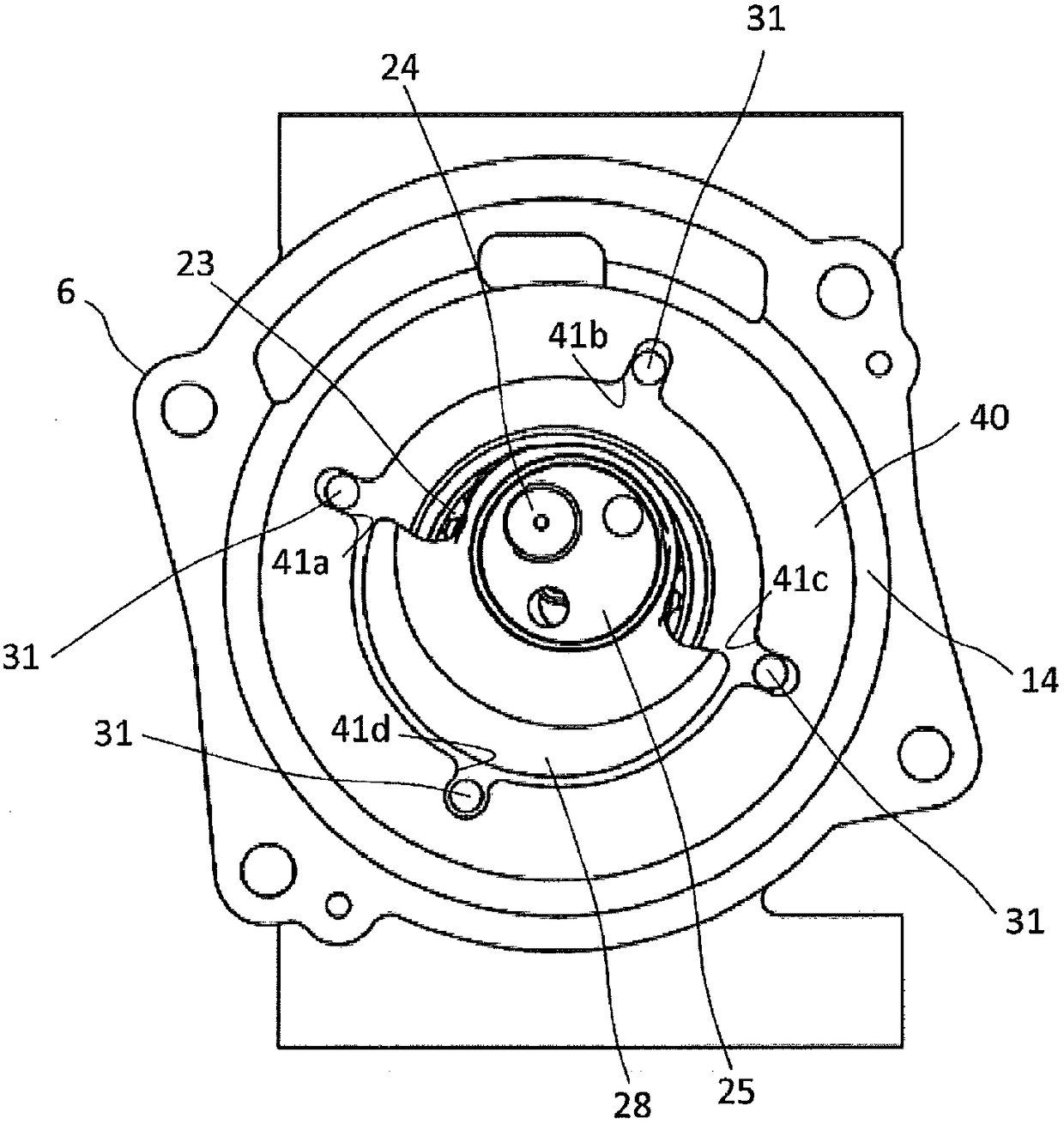

[0039] Figure 1 ~ Figure 4 The overall structure of the scroll compressor of the first embodiment is shown, figure 1 is the main view, figure 2 is along figure 1 The sectional view of the A-A line, image 3 is a structural diagram of the front case side viewed from the center case side, Figure 4 is a top view of the sliding board.

[0040] The scroll compressor 1 includes a scroll unit 4 having a fixed scroll 2 and a movable scroll 3 arranged opposite to each other along a central axis direction. Such as figure 2 As shown, the fixed scroll 2 is formed by integrally forming a scroll wrap 2b on an end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com