Energy-efficient double-output portable hydraulic power station

A hydraulic power station, dual-output technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as engine failure, system damage, and accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

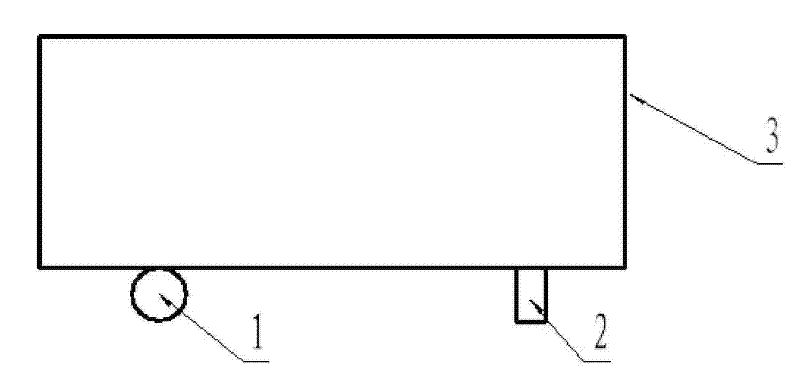

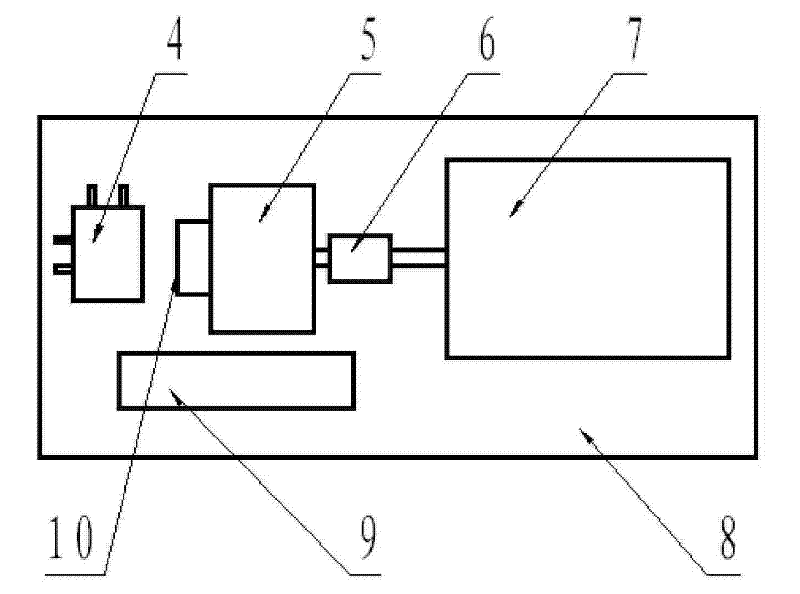

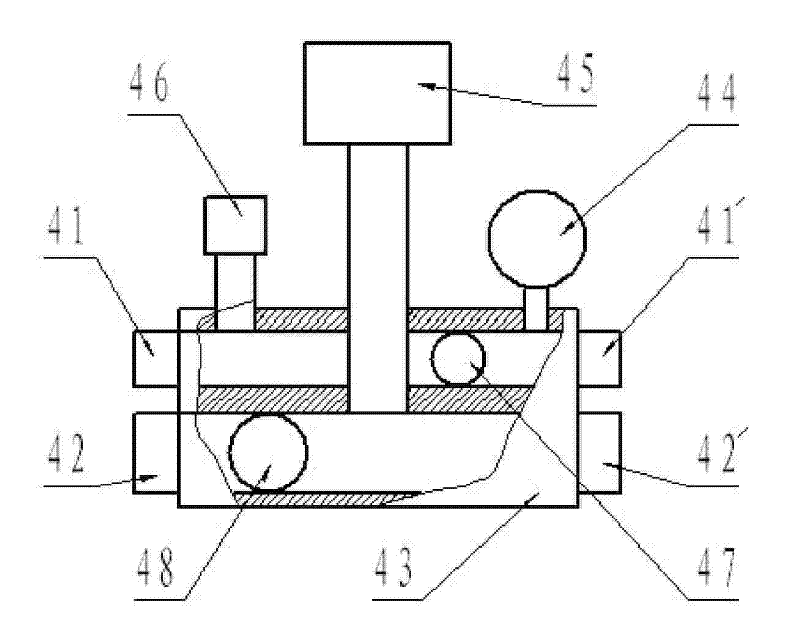

[0017] With reference to Fig. 1, present embodiment comprises base 8, hydraulic control valve seat assembly 4, air-cooled heat dissipation system assembly 5, gasoline engine assembly 7, described base 8 bottom is provided with moving wheel 1 and shock absorber 2, base The outer frame 3 is fixed on the side of 8 by screws, the hydraulic oil tank assembly 9 is fixed on the front of the left end of the base 8, the rear side of the hydraulic oil tank assembly 9 is welded with the air-cooled heat dissipation system assembly 5, and the lower part of the air-cooled heat dissipation system assembly 5 Equipped with a gear pump 10, the gear pump 10 is connected with the gasoline engine assembly 7 through a coupling 6, and the hydraulic control valve seat assembly 4, the air-cooled heat dissipation system assembly 5 and the gasoline engine assembly 7 are all installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com