A method and device for preventing secondary explosion after polymer polymerization explosion

A technology of secondary explosion and polymerization reaction, which is applied in instruments, computer control, simulators, etc., can solve the problems of secondary explosion, error while busy, increase secondary explosion, etc., and achieve good effect, strong practicability and easy realization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

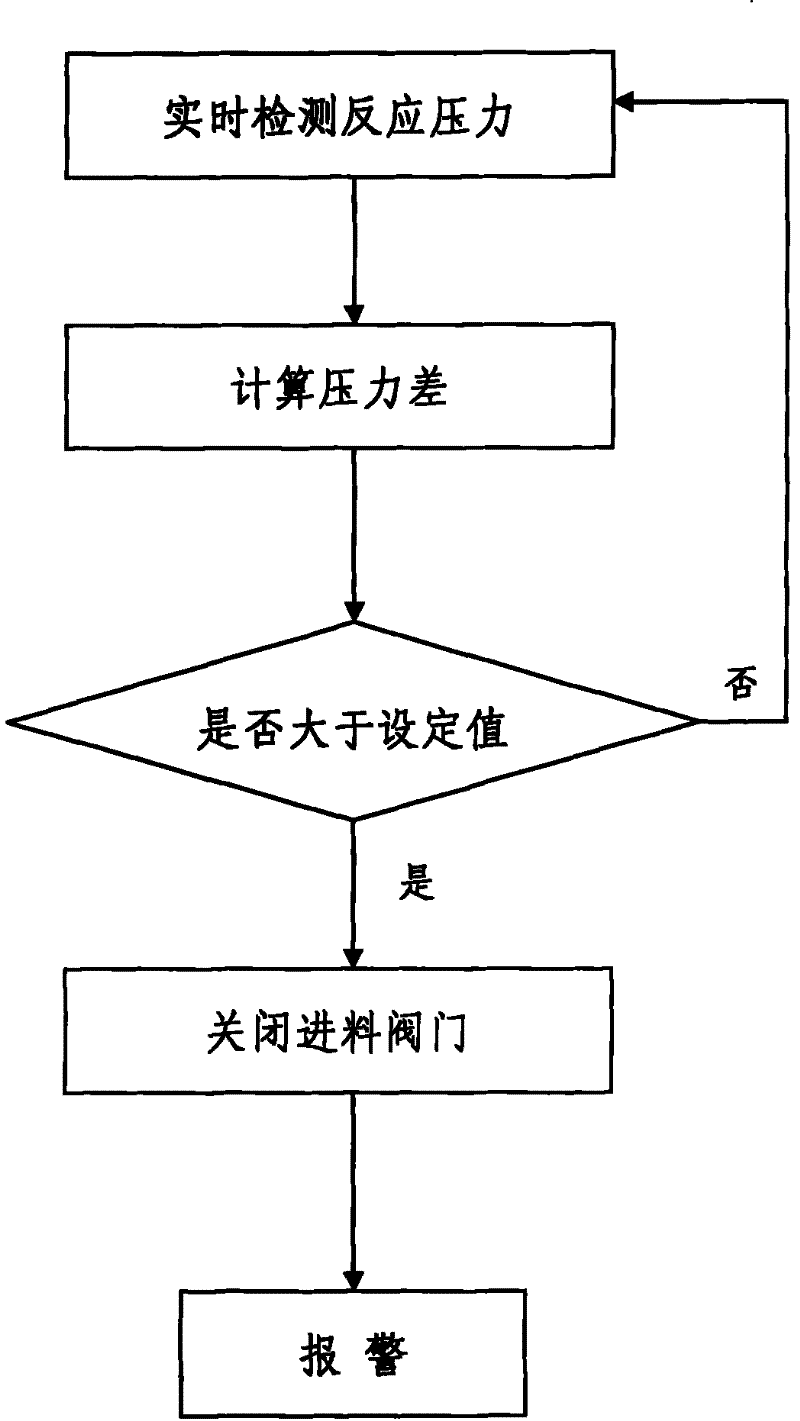

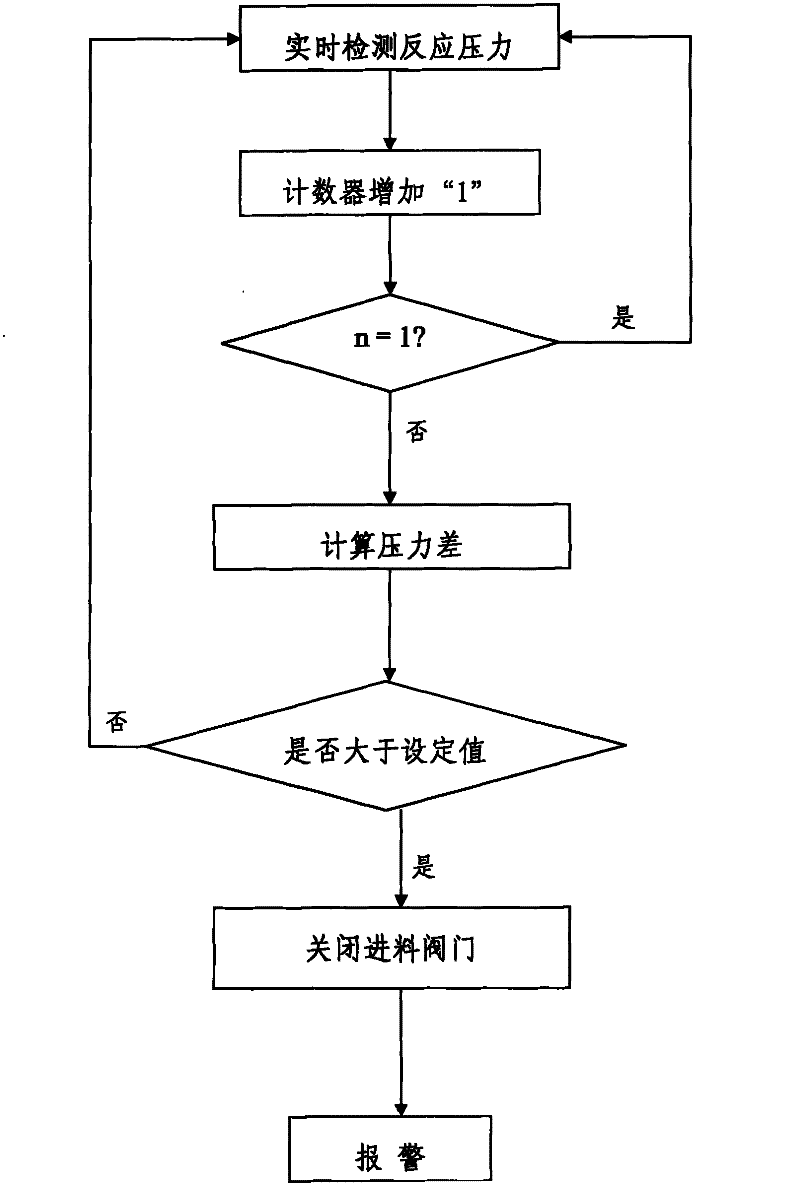

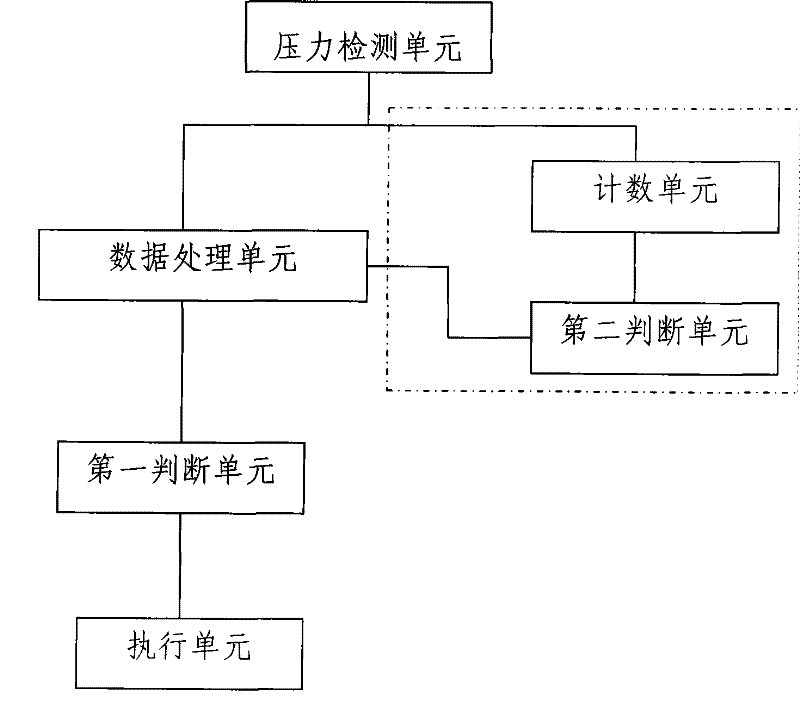

[0042] Combine below figure 1 , 2, 3, detail the method and device for preventing secondary explosion of polymerization involved in the present invention. The method for preventing polymerization secondary explosion of the present invention comprises the following steps (see figure 1 ):

[0043] 1. Real-time detection of reaction pressure during the polymerization process: P 1 ,P 2 ,P 3 ,P 4 ......P n-1 with P n ;

[0044] Install a pressure transmitter at a position about 300mm from the top of the reactor, with an accuracy of 0.1Kpa, to obtain the pressure of the reaction process, and convert the measured pressure value into an electrical signal and transmit it to the computer;

[0045] 2. Calculate the pressure difference: P n -P n-1 : The pressure value P measured later by the computer nSubtract the pressure value P meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com