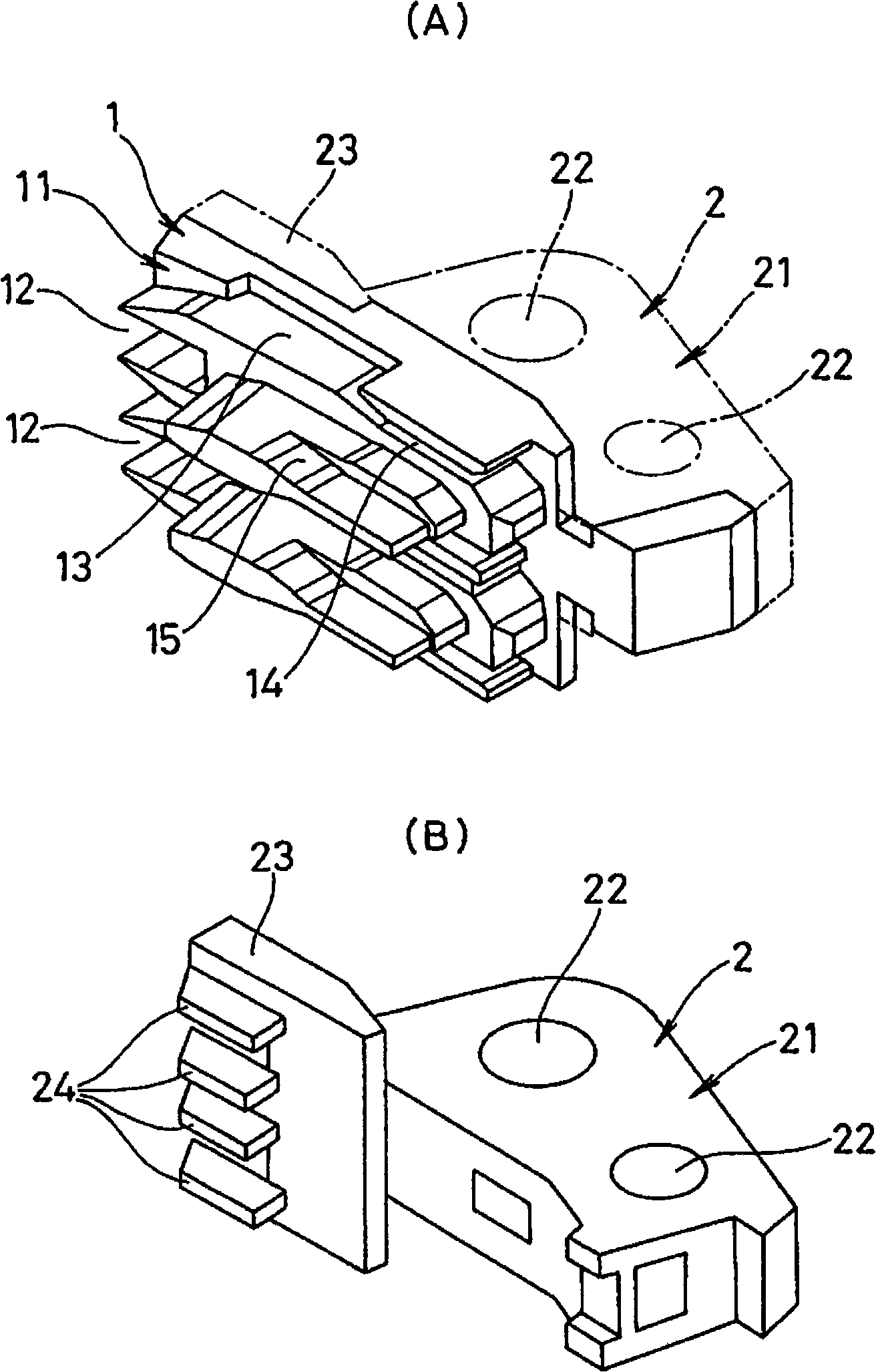

Ramp for magnetic disc apparatus

A technology of disk devices and ramps, applied in the configuration/installation of recording heads, structural parts of record carriers, data recording, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention includes the following embodiments.

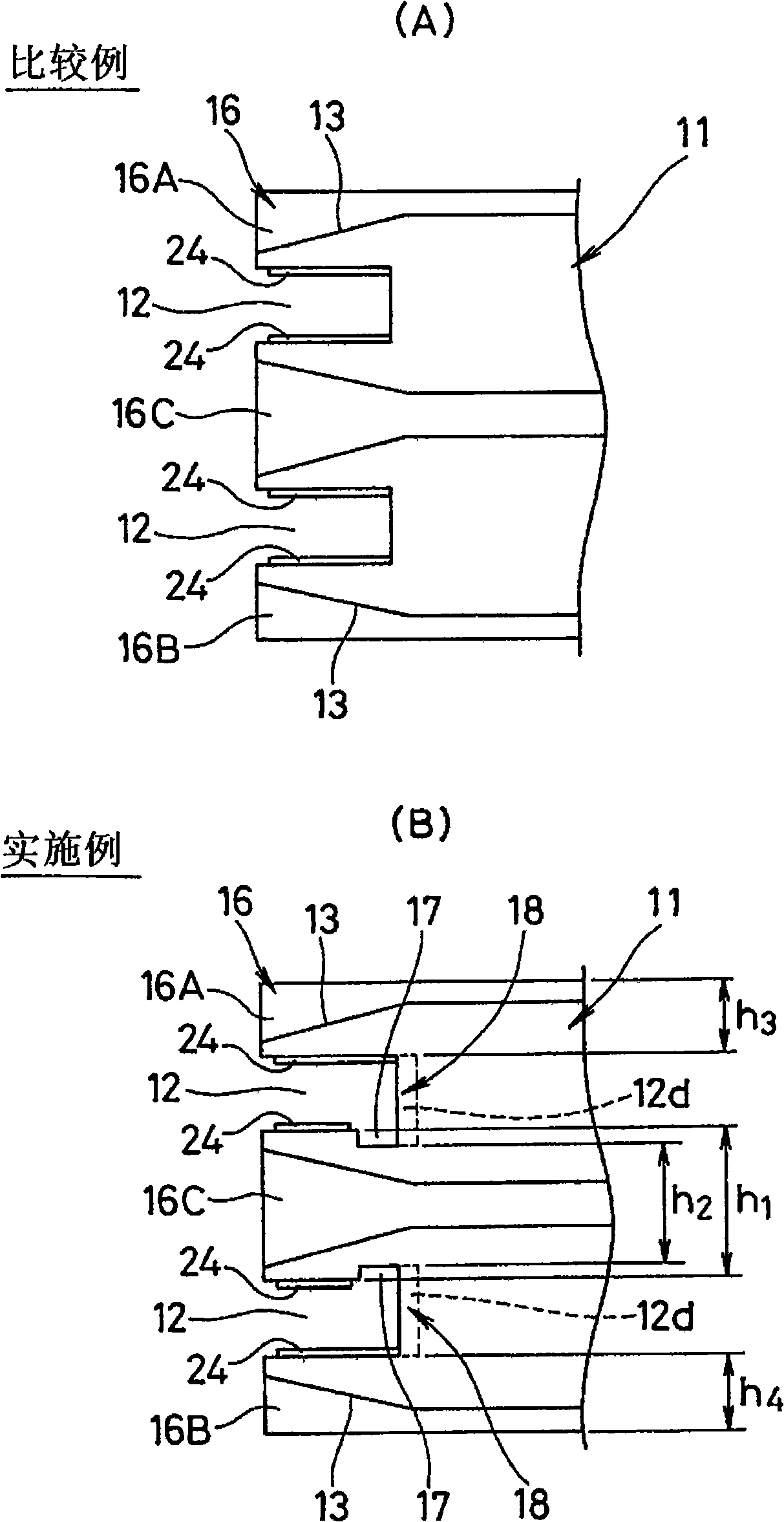

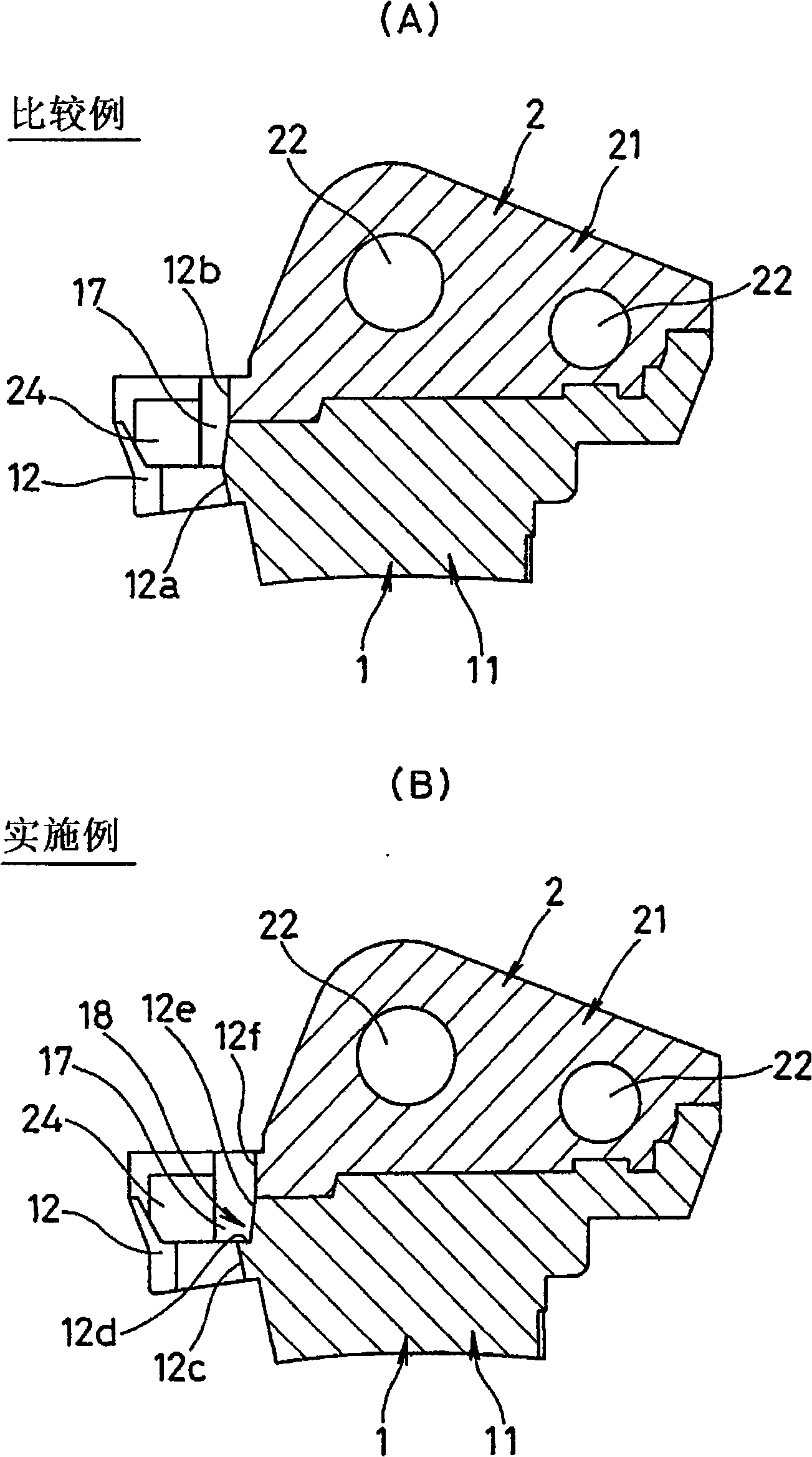

[0052] (1) That is, in order to increase the shock resistance and reduce the rigidity, and in the case of retracting the disk insertion part near the sliding part, the duckbill part (tip part) where the dimensional accuracy is most required will be lost in the direction of the disk. Distortion occurs and dimensional stability deteriorates.

[0053] (2) For this purpose, the depth of the disk insertion portion near the sliding portion is maintained, and the depth of the disk insertion portion at other locations is reduced.

[0054] (3) Further, by retracting the disk insertion portion only from the highly rigid resin, the volume of the highly rigid resin decreases while the volume of the slidable resin remains the same. As a result, a step is formed on the bottom surface of the disk insertion portion. By reducing the volume of the highly rigid resin, the rigidity of the disk insertion portion can be reduced.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com