High-current self-clean cam switch

A cam switch, self-cleaning technology, applied in the direction of contact meshing, contact drive mechanism, etc., can solve problems such as difficulty in adapting to high current, cam switch does not have self-cleaning function, etc., to achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

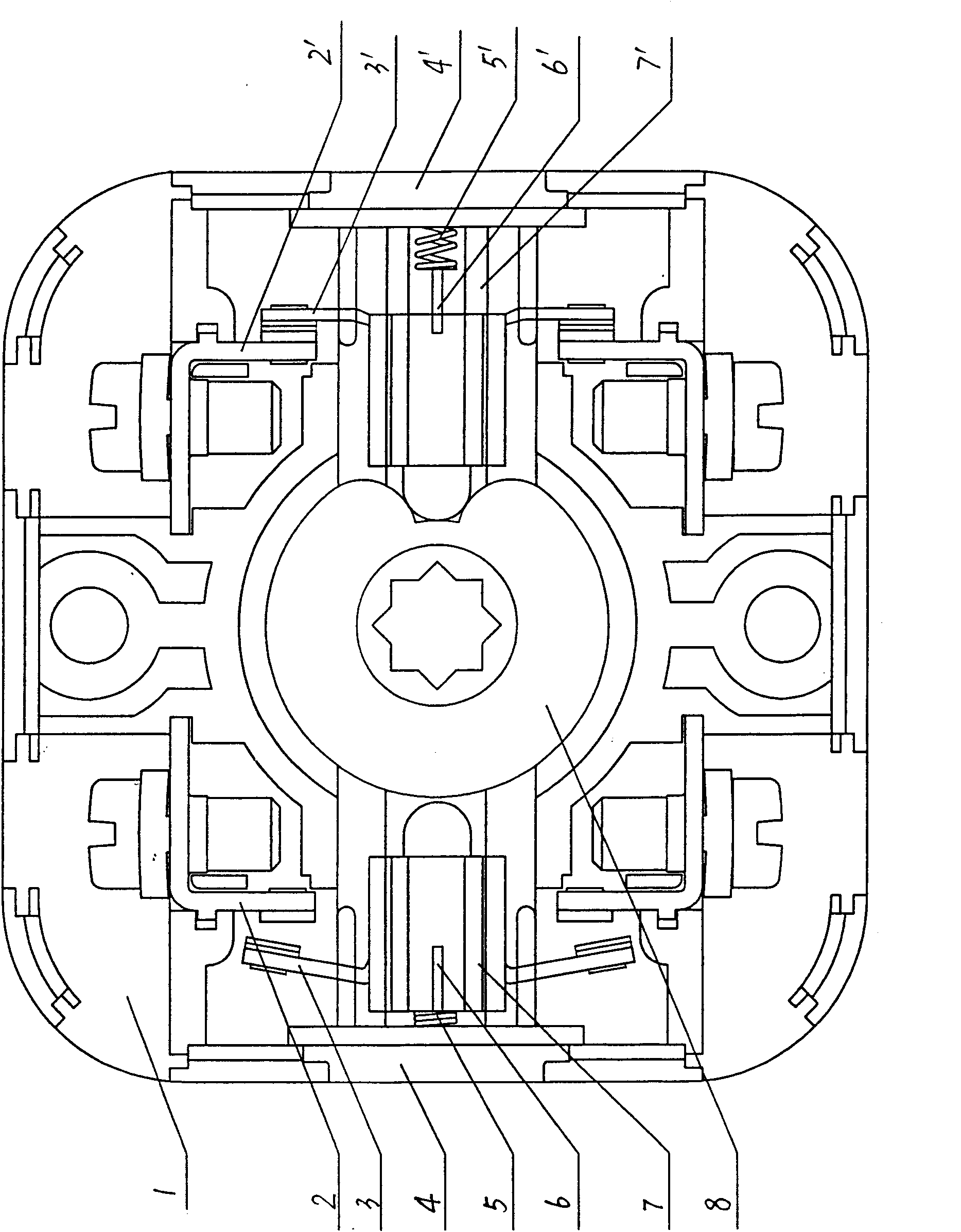

[0021] Such as figure 1 , figure 2 and image 3 as shown,

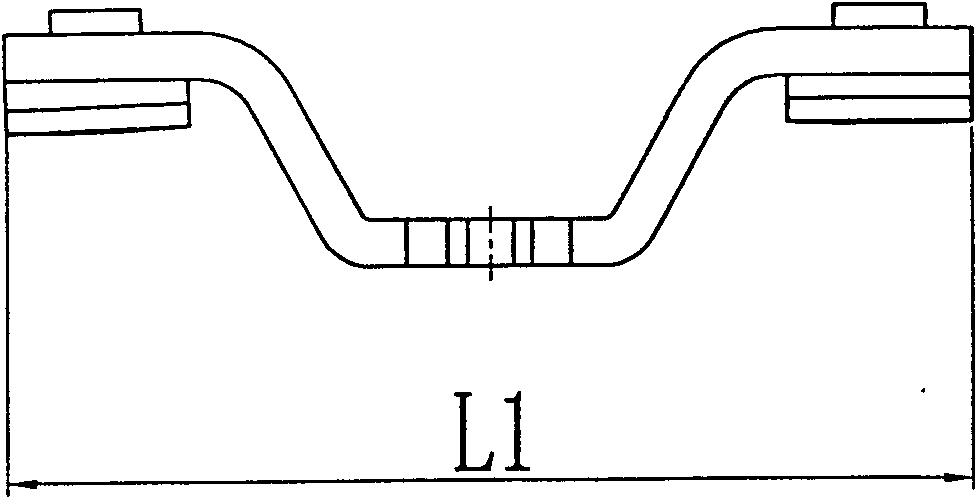

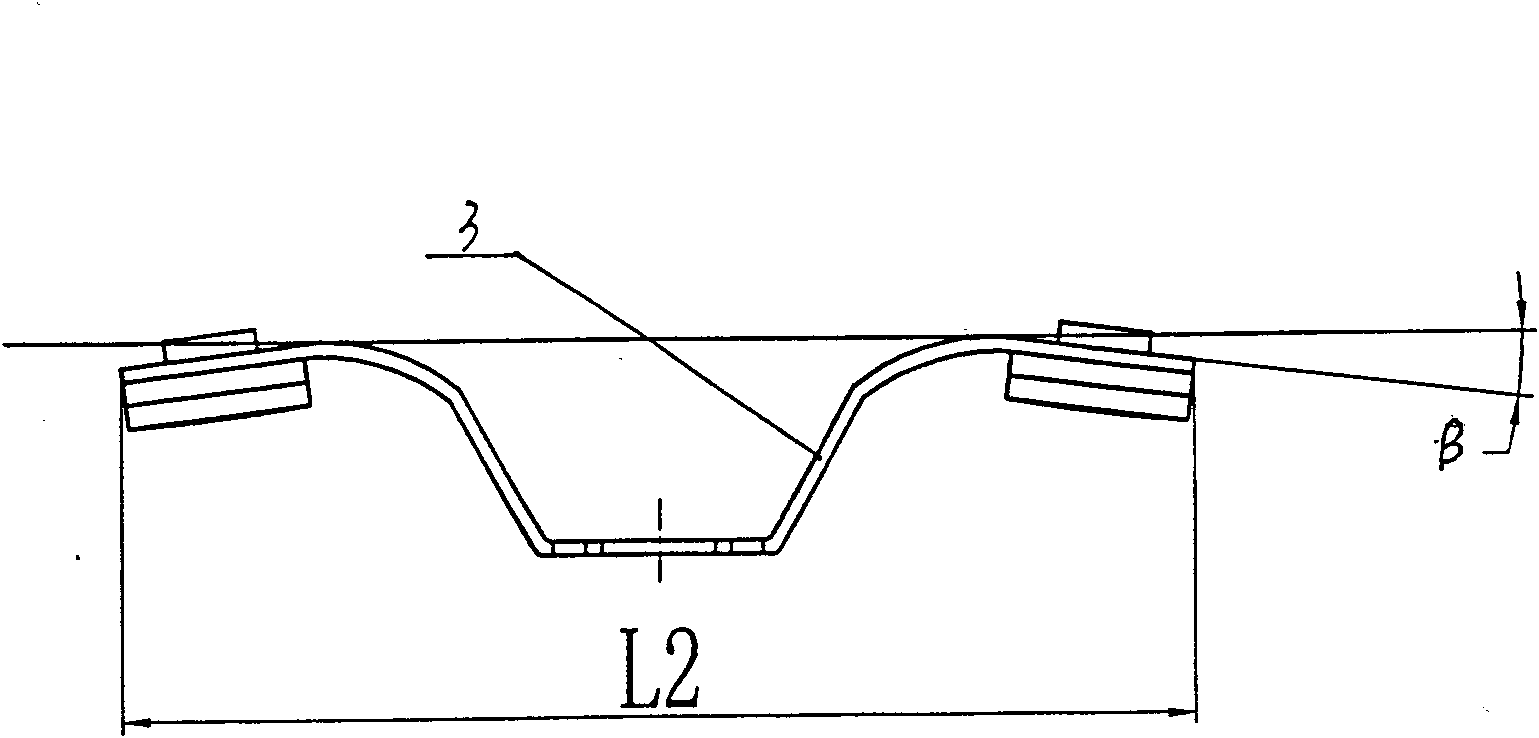

[0022] A high-current self-cleaning cam switch, comprising a contact base 1, a round hole is opened in the middle of the contact base 1, a cam 8 is arranged in the round hole, static contacts 2, 2', the two sides of the cam 8 are respectively provided with a bracket 7, 7', and a moving contact 3, 3' with a double contact is installed on the bracket 7, 7', and the moving contact 3 corresponds to the static contact 2, The moving contact 3' corresponds to the static contact 2', a pair of spring seats 4, 4' are arranged on both sides of the contact base 1, and a pair of spring seats 4, 4' are provided between the moving contacts 3, 3' and the spring seats 4, 4' The springs 5, 5' are compressed, and the contacts on both sides of the movable contacts 3, 3' are inclined to the direction of the cam 8 by an angle β, image 3 The length of the moving contact 3, 3' in is L2, figure 2 The length of the standard moving cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com