Safe coiling type lithium battery

A wound-type lithium battery technology, applied in secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as local overheating, affecting safety performance, and loss of stability in battery internal pressure, etc., to maintain The effect of internal pressure balance and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

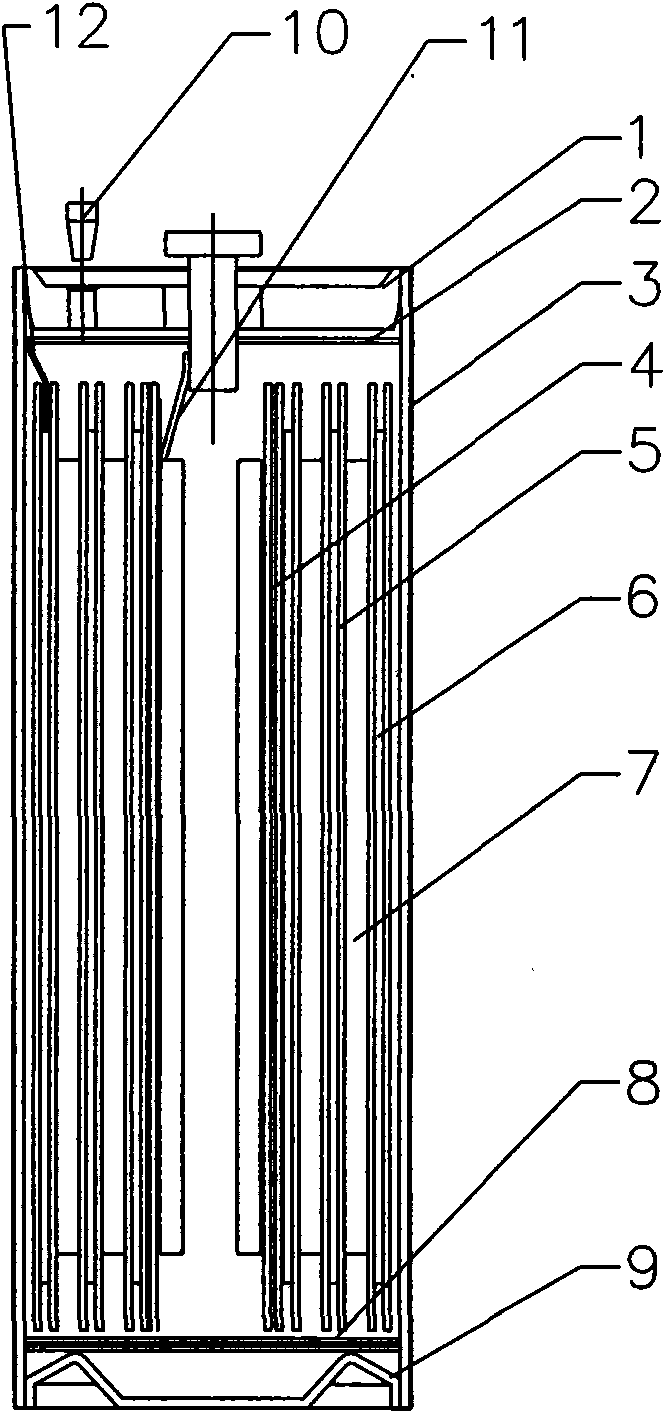

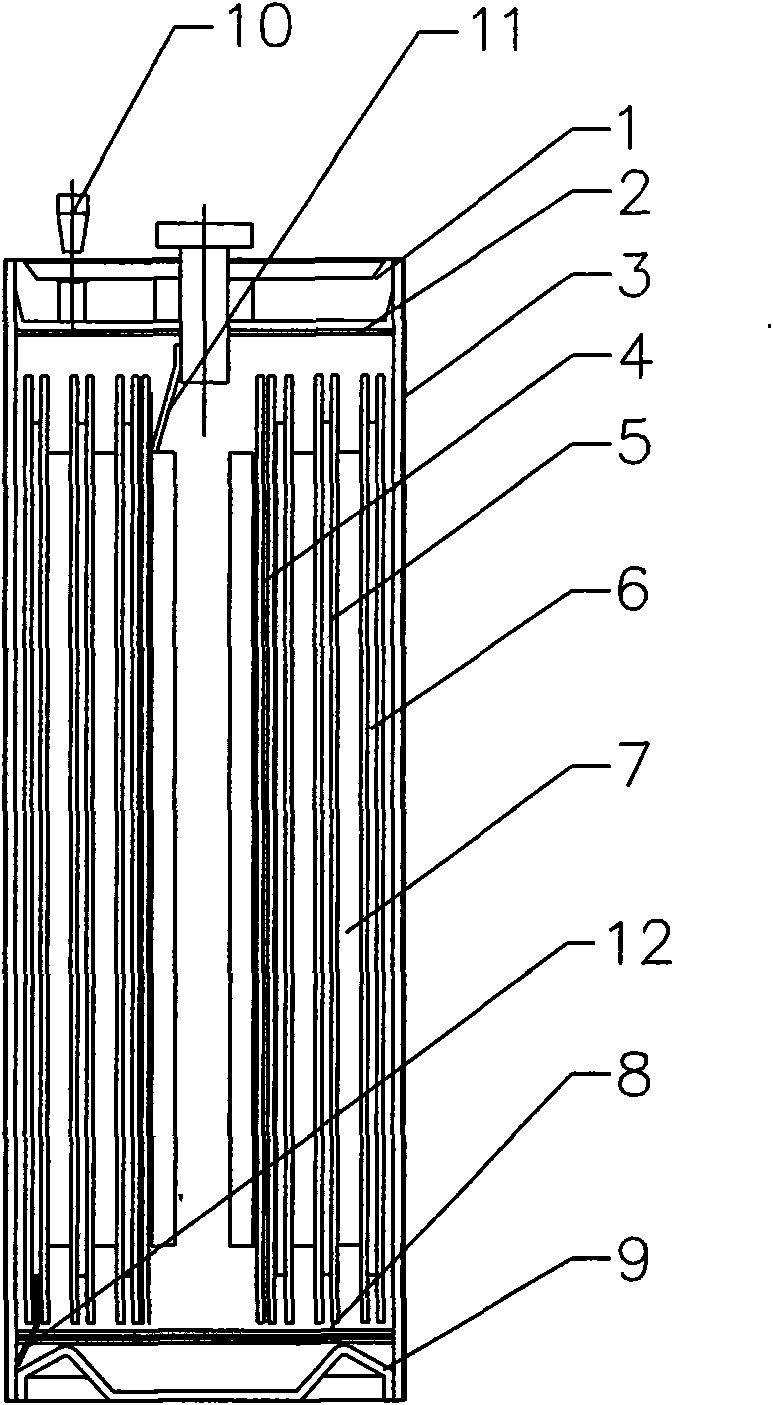

[0017] The improvement of the present invention lies in that the positive and negative electrodes of the wound lithium battery are drawn out from the upper and lower ends of the battery, respectively. The positive and negative electrodes are located at both ends of the battery. The habit drawn from the cap at the upper end of the battery makes a significant change in the structure of the battery, and at the same time, this structural change can also significantly improve the safety of the battery.

[0018] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings:

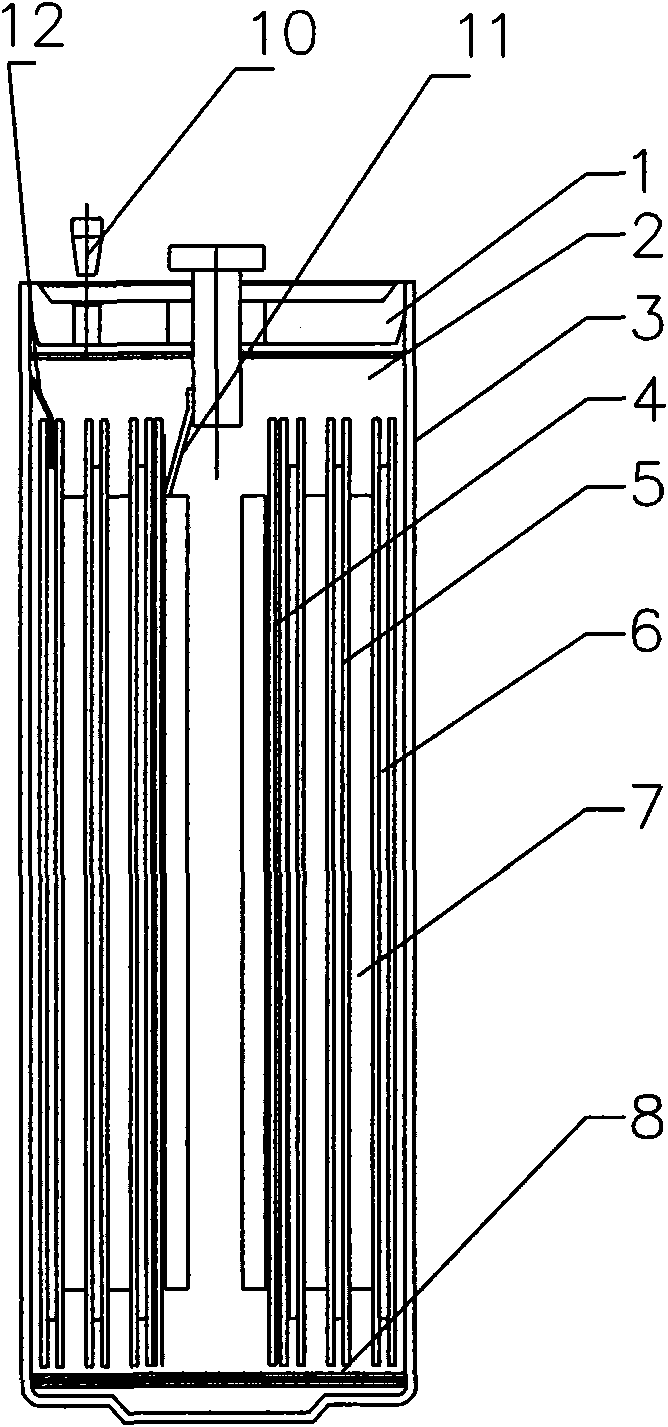

[0019] see image 3 , a winding type lithium battery structure, which comprises a battery case 3, a wound cell is placed in the battery case, and the cell is separated by a positive electrode 7 carbon sheet and a negative electrode 6 lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com