Vacuum pump

A technology for vacuum pumps and substrates, applied in pumps, pump components, rotary piston pumps, etc., can solve problems such as poor heat dissipation and high noise, and achieve the effects of slowing down the airflow speed, reducing noise, and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

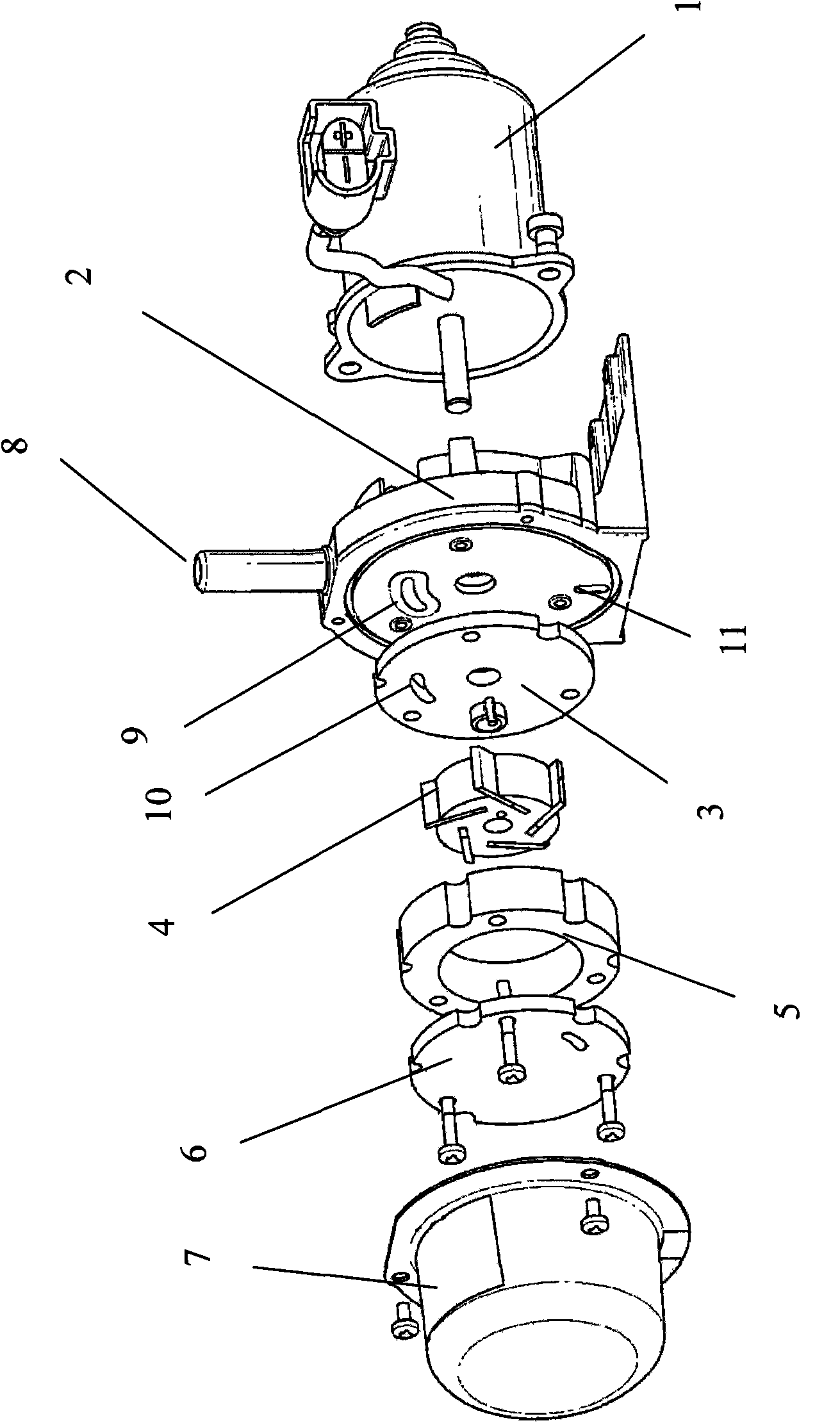

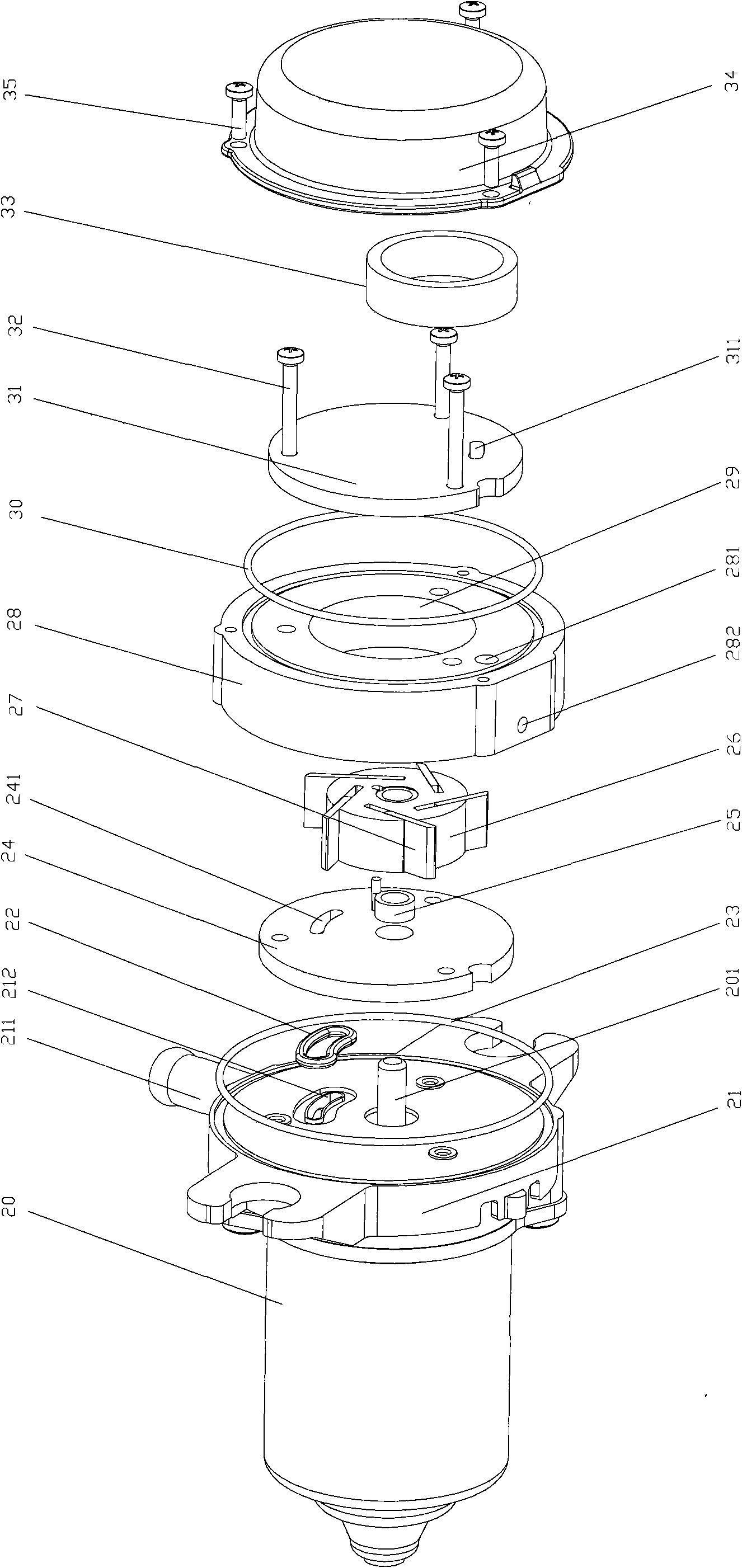

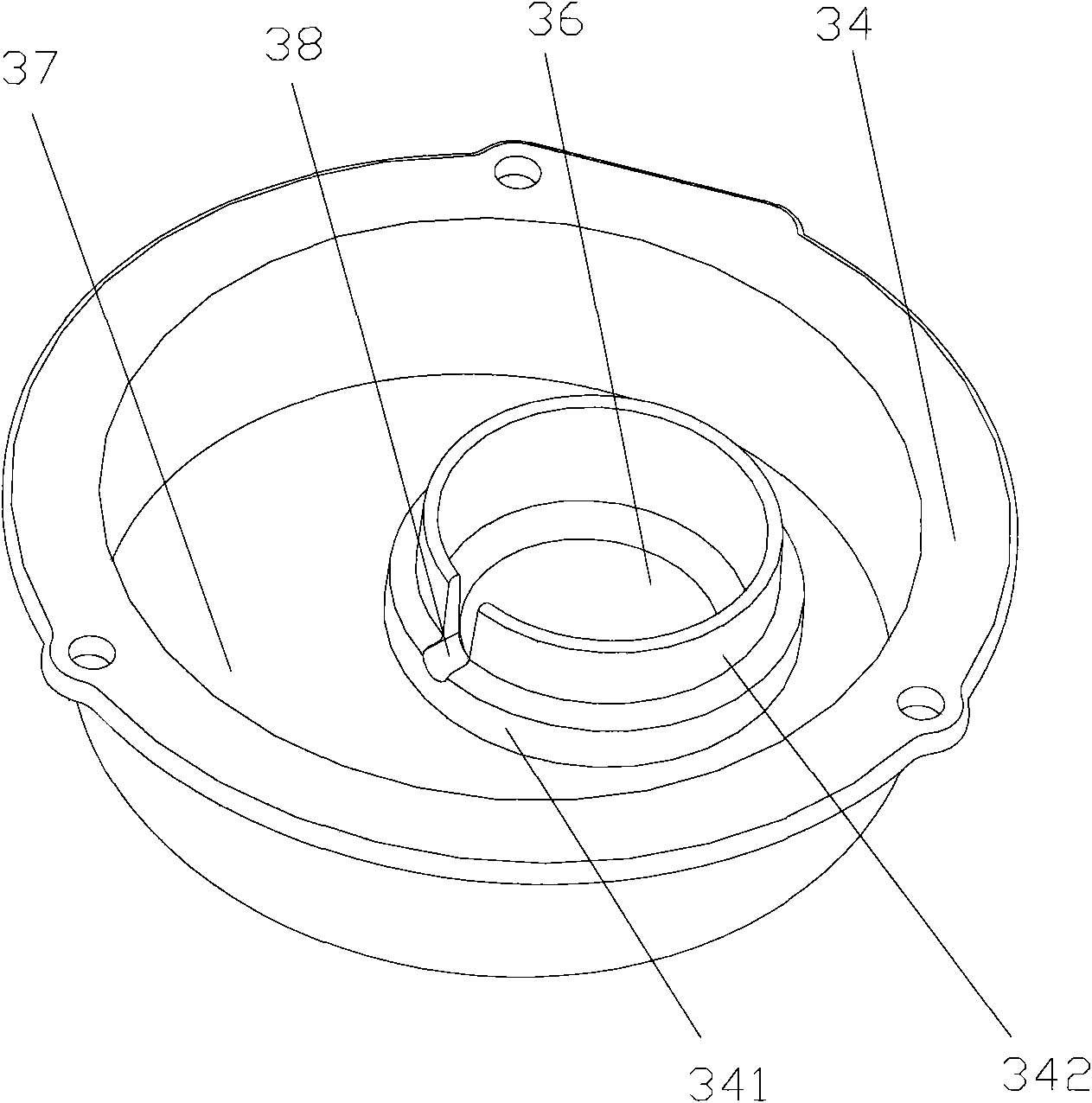

[0012] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] Before going into details, it should first be explained that, unless otherwise specified, the "upper end" mentioned in the claims and description of the present invention refers to the side close to the first substrate along the axial direction of the mount ( which is figure 2 The end of the upper side), the "lower end" refers to the side close to the driver along the axial direction of the mounting seat (ie figure 2 The end of the lower side), similarly, the "upper" and "lower" mentioned in the claims and description of the present invention refer to figure 2 The upper and lower sides are shown for ease of description.

[0014] Such as figure 2 As shown, a vacuum pump is provided according to an embodiment of the present invention, and the vacuum pump includes:

[0015] a drive 20 with a drive shaft 201;

[0016] The mounting ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com