Soft packing lithium ion battery and method of producing same

A technology of lithium-ion battery and manufacturing method, which is applied in the manufacture of soft-packaged lithium-ion batteries and in the field of soft-packaged lithium-ion batteries, can solve the problem of difficult control of the center distance between the positive and negative tabs, difficulty in matching the center distance of the battery cell with the center distance of the protective plate, and difficulty in positive , the precise positioning of the negative tab, etc., to meet the requirements of the center distance of the tab, reduce inventory, and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Manufacturing method of flexible packaging lithium-ion battery

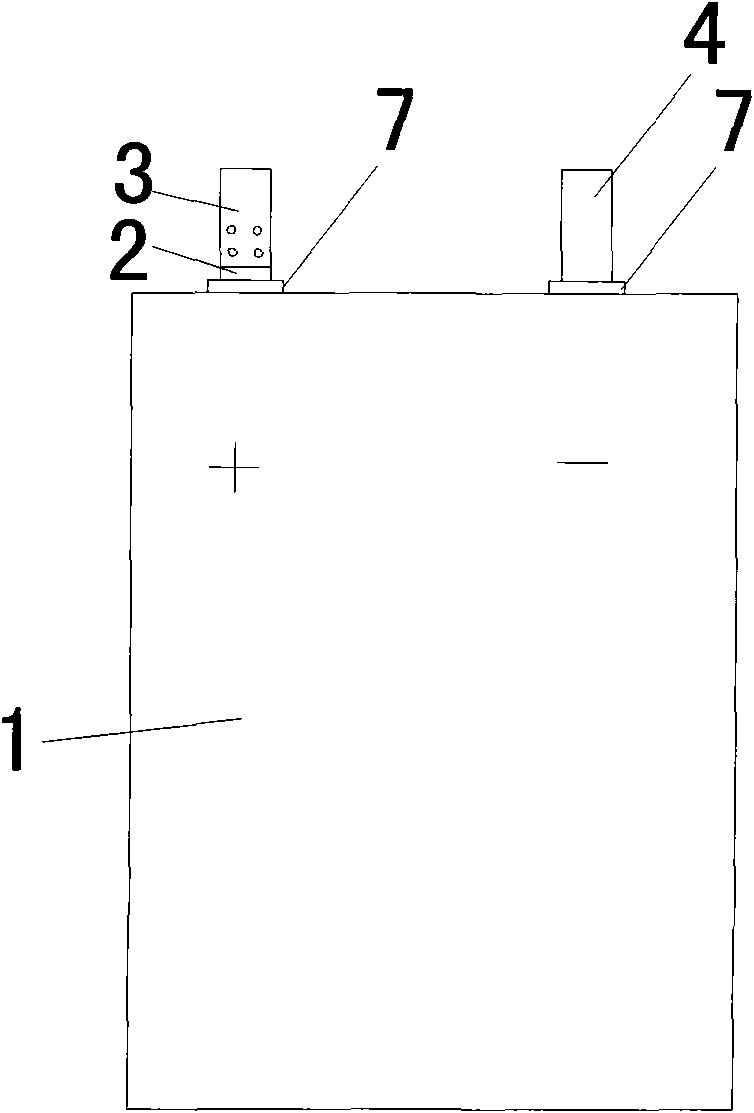

[0043] see figure 1 , shows the structure of the formed cell 1; the positive tab is made of a nickel strip 3 welded on an aluminum strip 2, and the positive tab is welded on the positive sheet; the negative tab is a nickel strip 4, and the negative tab is welded on the negative sheet The positive electrode sheet and the negative electrode sheet are wound or laminated to form the battery core 1, and a small part of the aluminum strip 2 and the nickel strip 3 of the positive tab are exposed outside the battery core 1, and the nickel strip 4 of the negative tab is also partially exposed on the battery core. 1 outside.

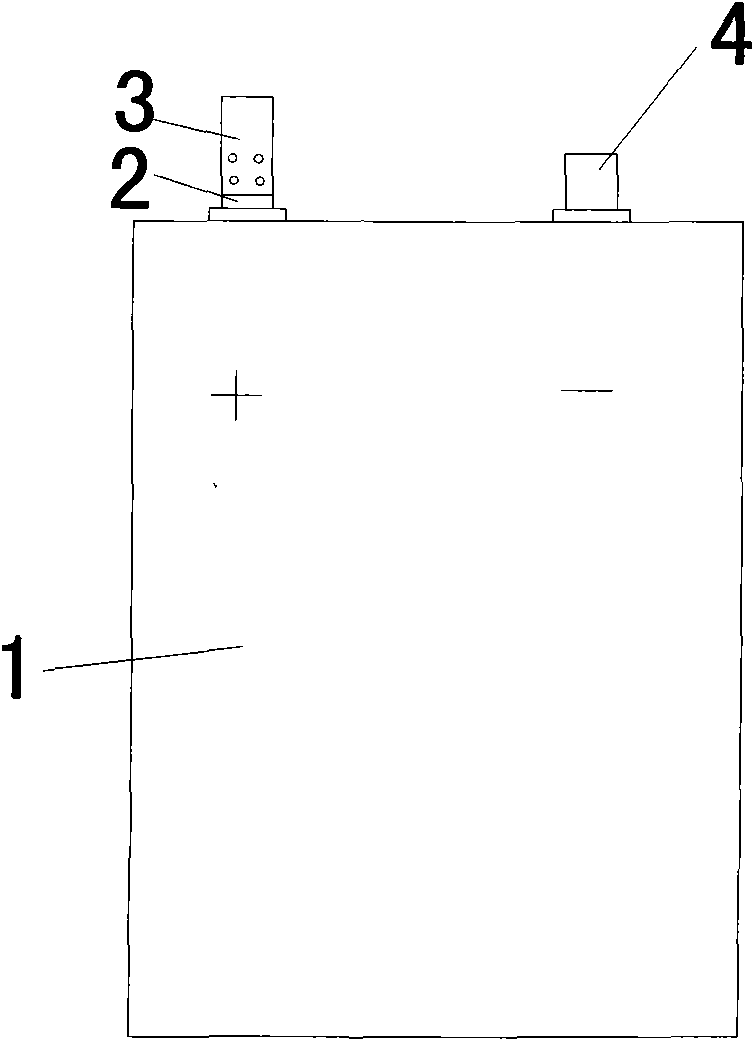

[0044] see figure 2 The nickel strip 4 of the negative tab is used as the base strip, and the exposed part of the base strip 4 outside the cell 1 is cut into a suitable shape and size. The so-called suitable shape and size means that the remaining exposed part matches the adj...

Embodiment 2

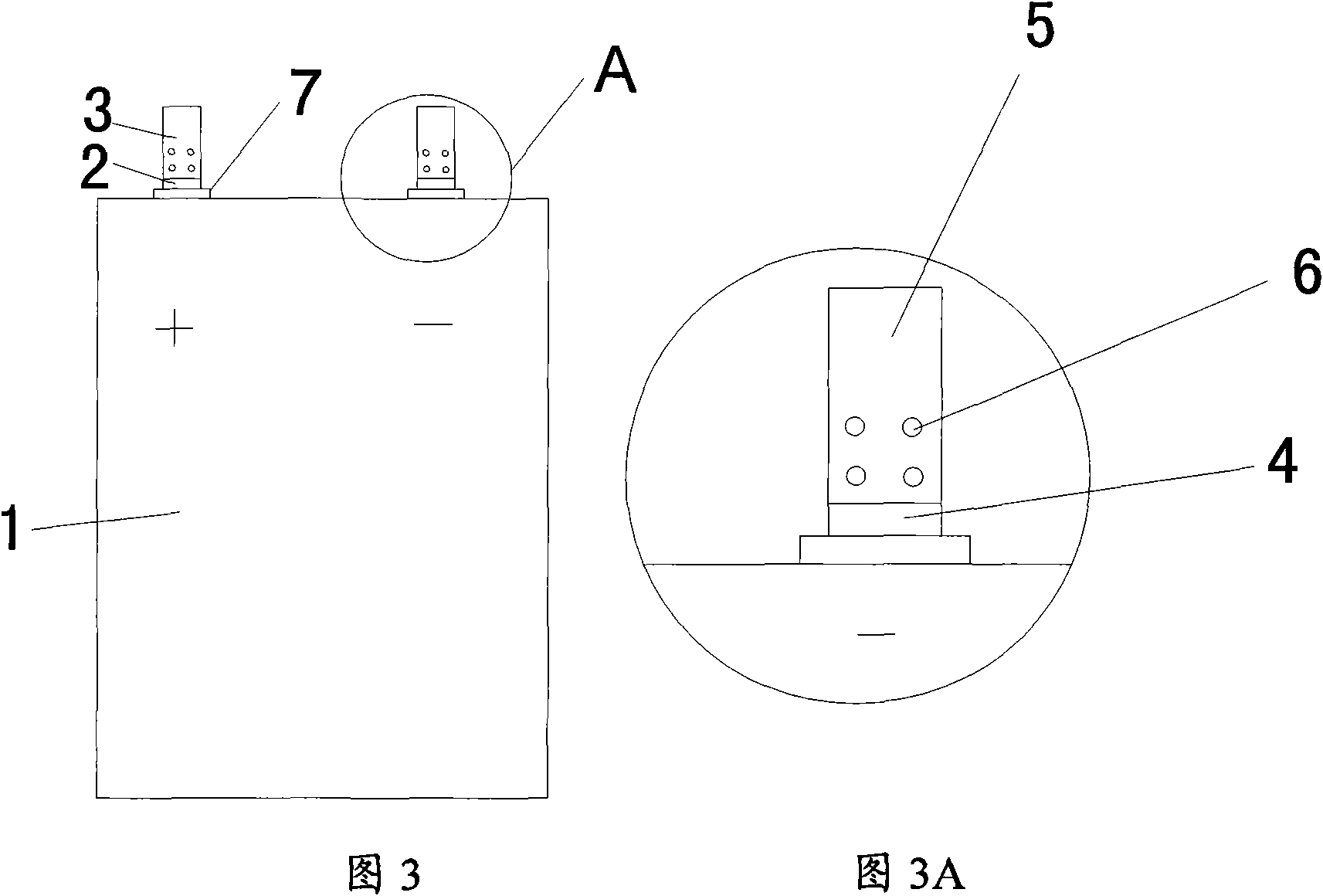

[0048] Example 2: Flexible packaging lithium-ion battery

[0049] The battery cell 1 is provided with a positive pole ear and a negative pole ear, and the positive pole ear and the negative pole ear are set with a sealing ring 7 near the battery core 1; The nickel strip 3 on the exposed part of the aluminum strip 2; the negative tab is cut into a suitable shape and size by cutting the exposed part of the base strip 4 made of the nickel metal strip outside the battery core 1, and then adjusting the nickel metal strip. The strip 5 is electrically connected to the remaining exposed part of the base strip 4 by welding to form a new negative tab. The center distance of the positive and negative tabs fluctuates within the specified range to ensure a high pass rate of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com