Wire harness fixture, wire harness device with fixture, and method of manufacturing wire harness device with fixture

A technology for wire harness fixing and fixing parts, which is applied in packaging, electrical components, transportation and packaging, etc., and can solve problems such as staggered straps, loose straps, and staggered installation positions of fixing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the wire harness anchor and the wire harness device with the anchor according to the embodiment will be described.

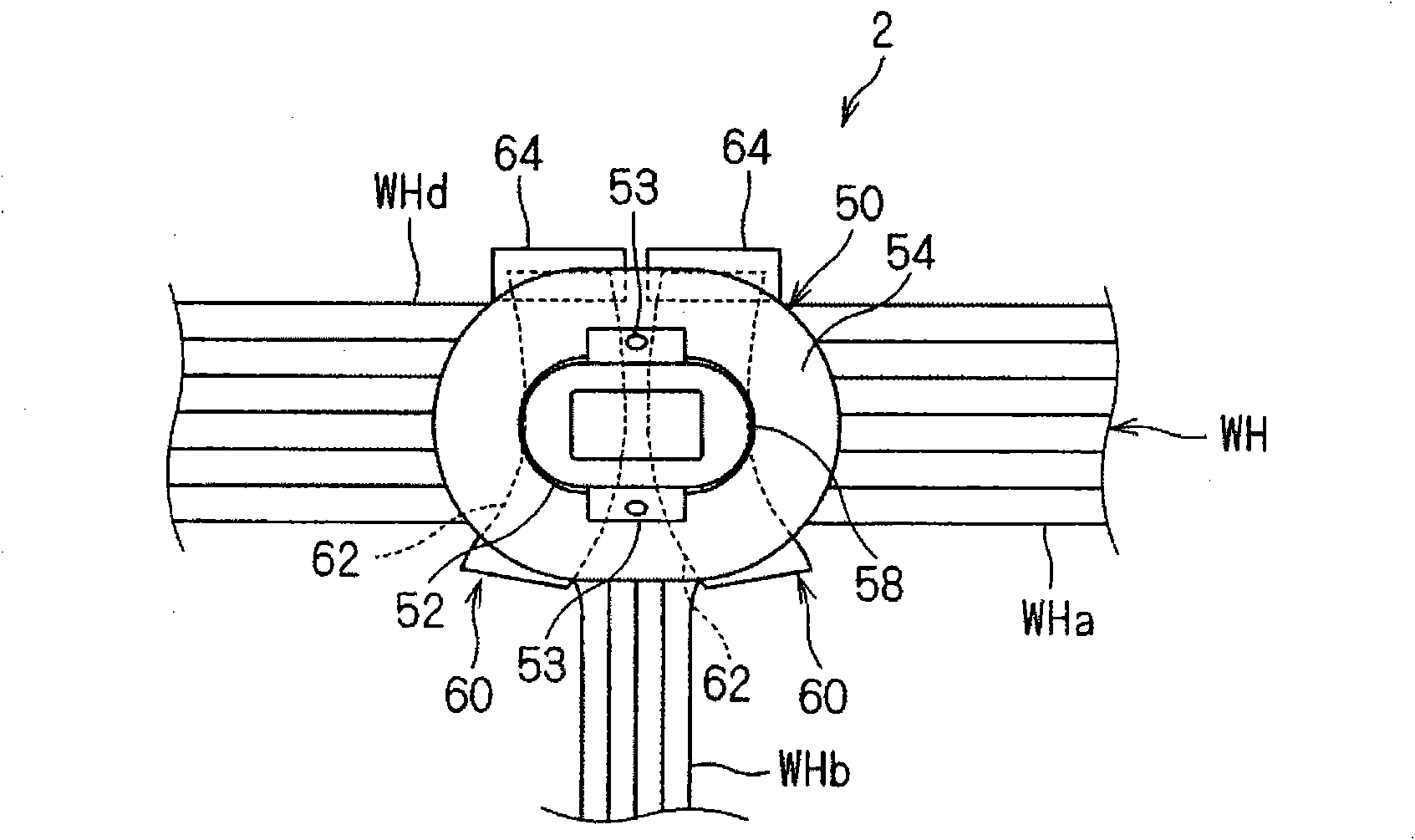

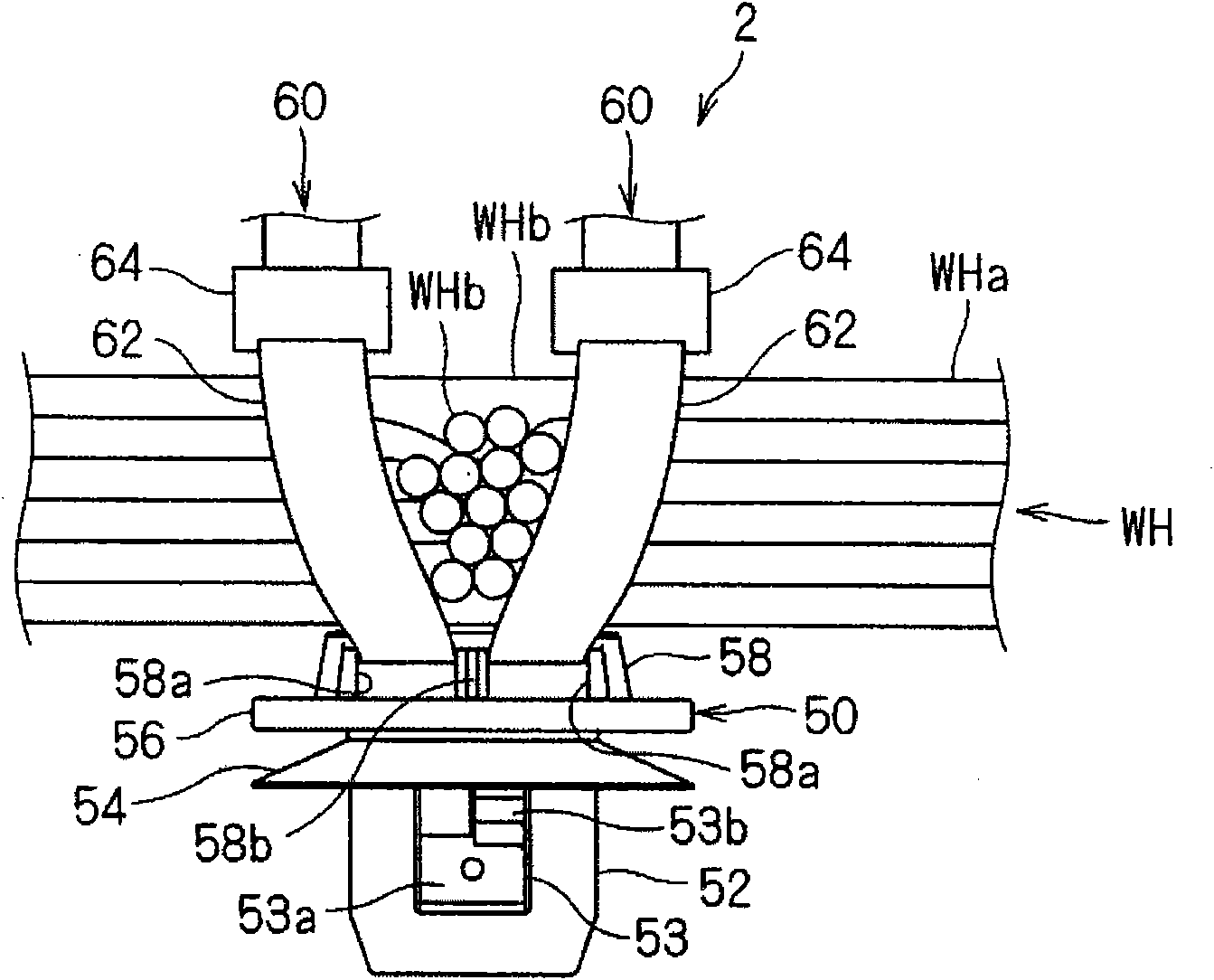

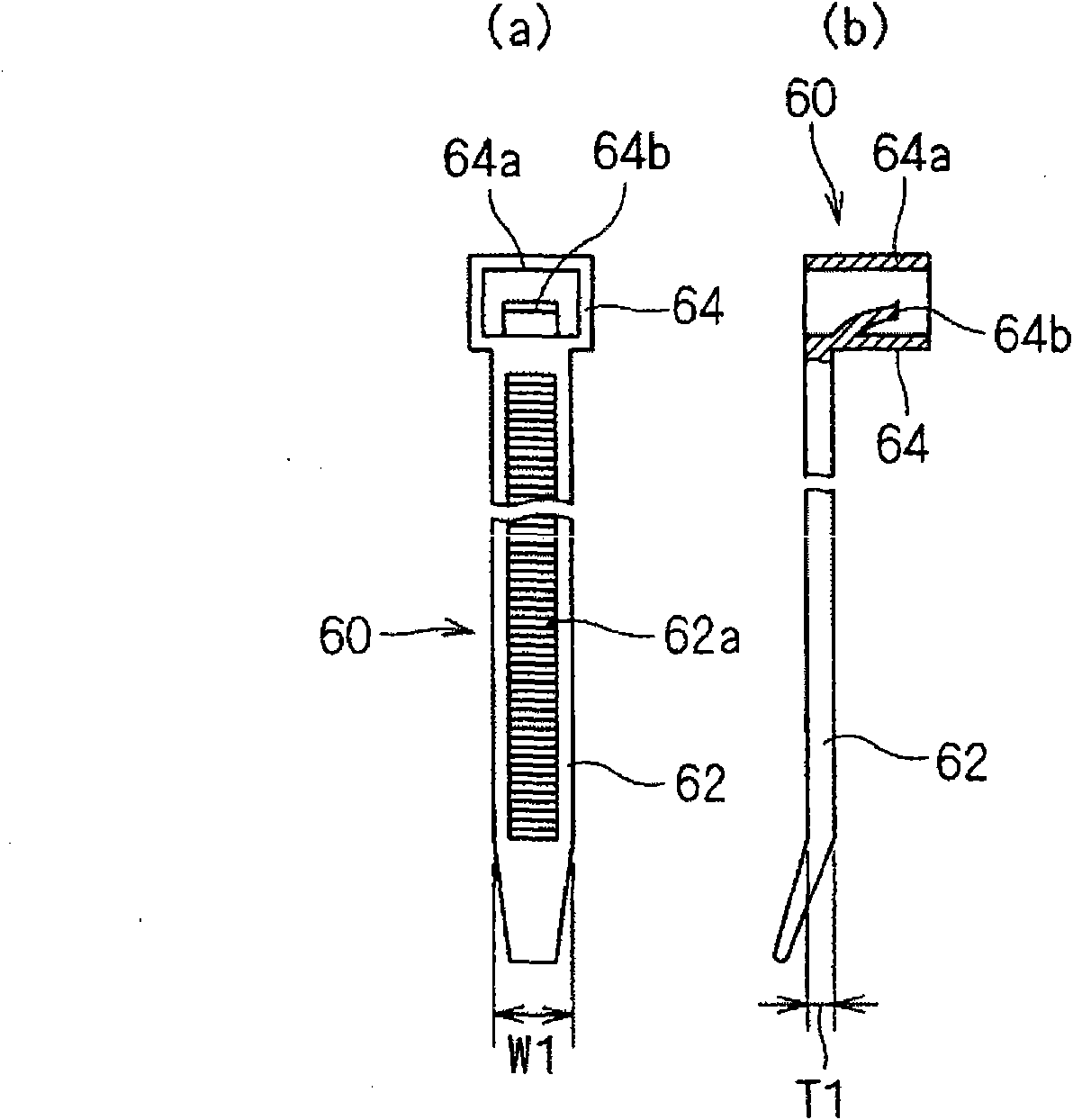

[0039] figure 1 It is a bottom view showing the branch part of the harness device with the fixing parts, figure 2 It is a side view showing the branched part of the harness device with the fastener.

[0040] The wire harness device 2 with a fastener includes a wire harness WH, a pair of binding bands 60 , and a wire harness fastener 50 , and is configured to be fixable to an attachment object.

[0041] The wire harness WH is, for example, a wiring member that connects various electric devices such as a vehicle, and is configured such that a plurality of electric wires are branched and bundled in a state corresponding to arrangement positions or wiring paths of various electric devices. In addition, the wire harness WH may include not only electric wires but also other wiring such as optical fibers.

[0042] In such a wire harness WH, a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com