Pit for managing dust removal

A technology for shafts and drainage pipes, applied in the direction of sewage removal, thin material treatment, water/sewage treatment, etc., can solve problems such as troublesome dust removal operations, and achieve the effects of reducing management burden, reducing the amount of dust and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

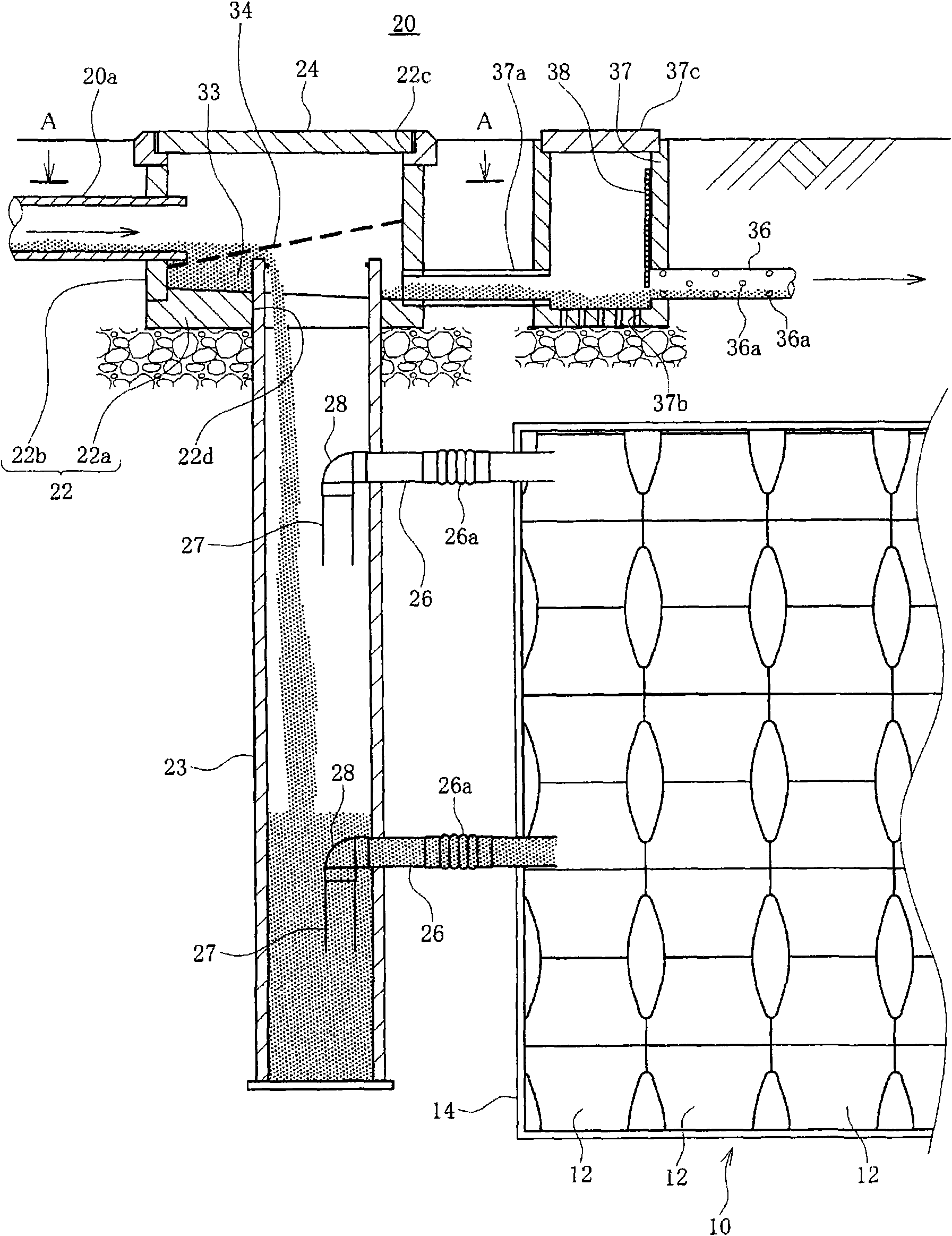

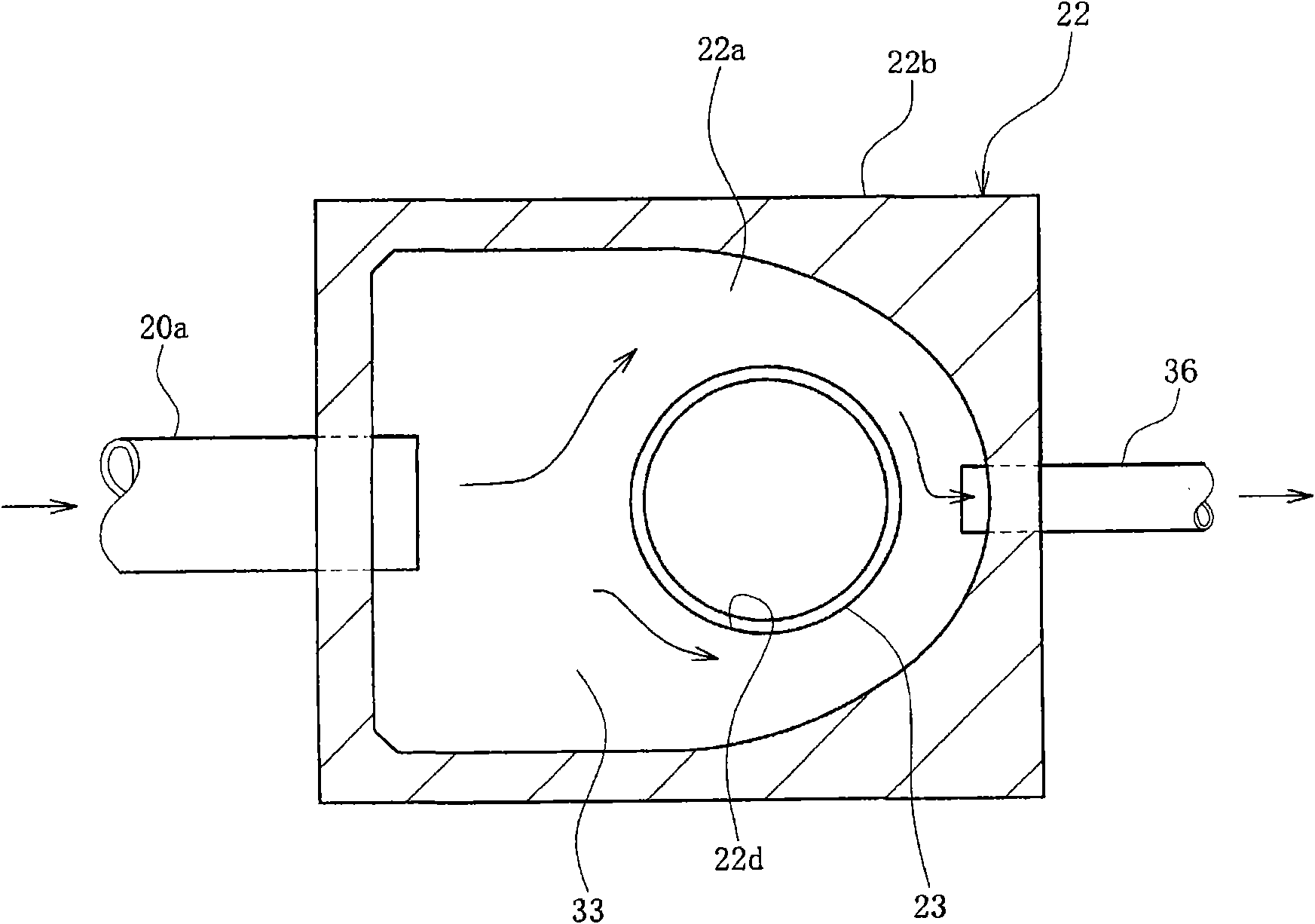

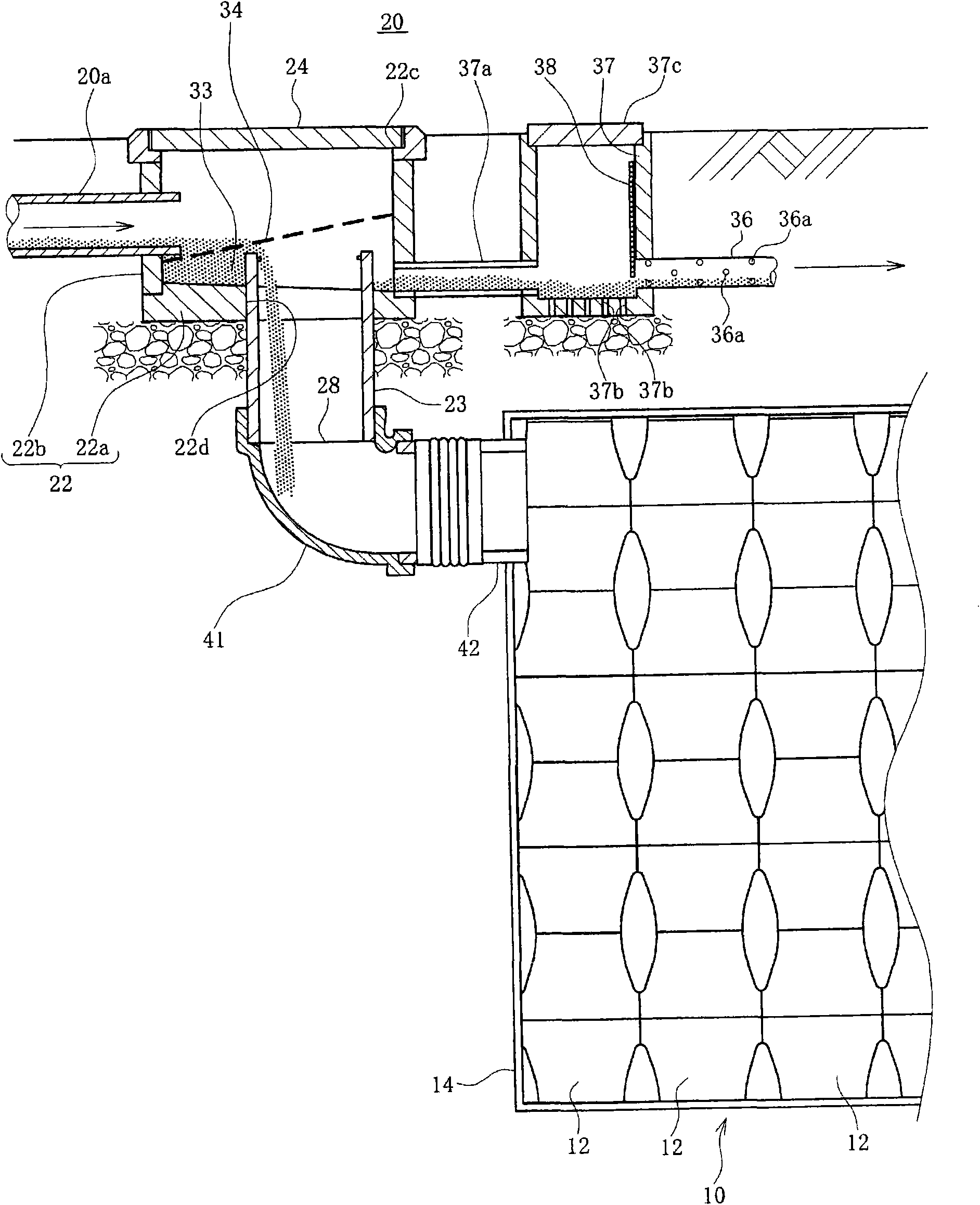

[0037] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

[0038] Such as figure 1 As shown, the dust removal management well 20 and the water storage tank 10 of this embodiment are connected and installed. The water storage tank 10 is buried in the ground, which means that the water storage tank 10 stores rainwater that falls on the roof or roof terrace or the ground of the house. A drainage unit not shown is used to pump out the water stored in the water. Reuse. figure 1 The water storage tank 10 of the example is formed by covering an assembly formed by combining a plurality of water storage materials 12 with a waterproof sheet 14. As the water storage material 12 of this embodiment, a plastic molded body 12 molded with a metal mold is used. The water storage material 12 composed of the plastic molded body is formed into a truncated pyramid shape, and after being arranged vertically and horizontally, the water storage m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com