Fluid sensor device

A fluid sensor and fluid technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of unprotected electrodes, and achieve the effect of simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

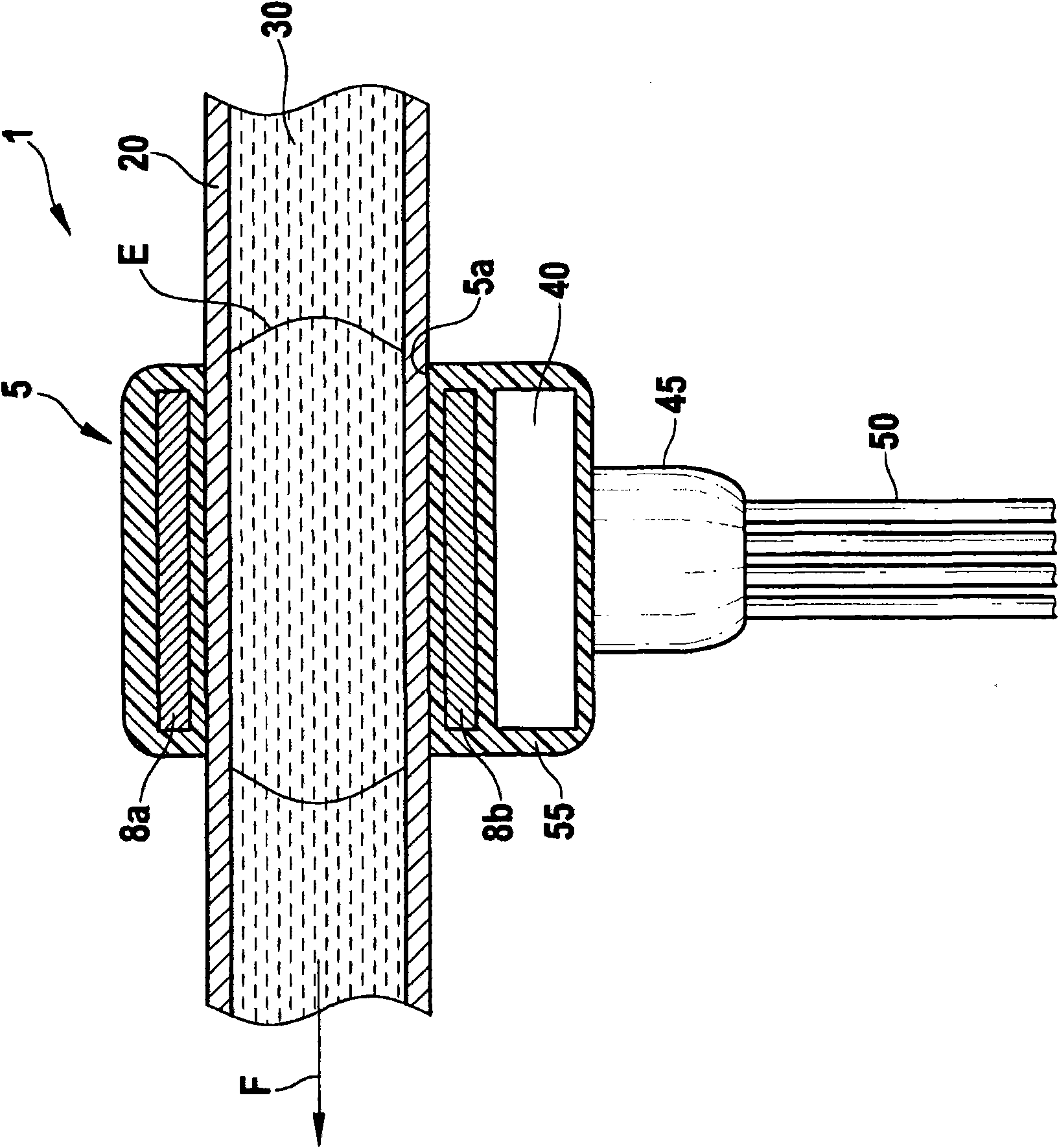

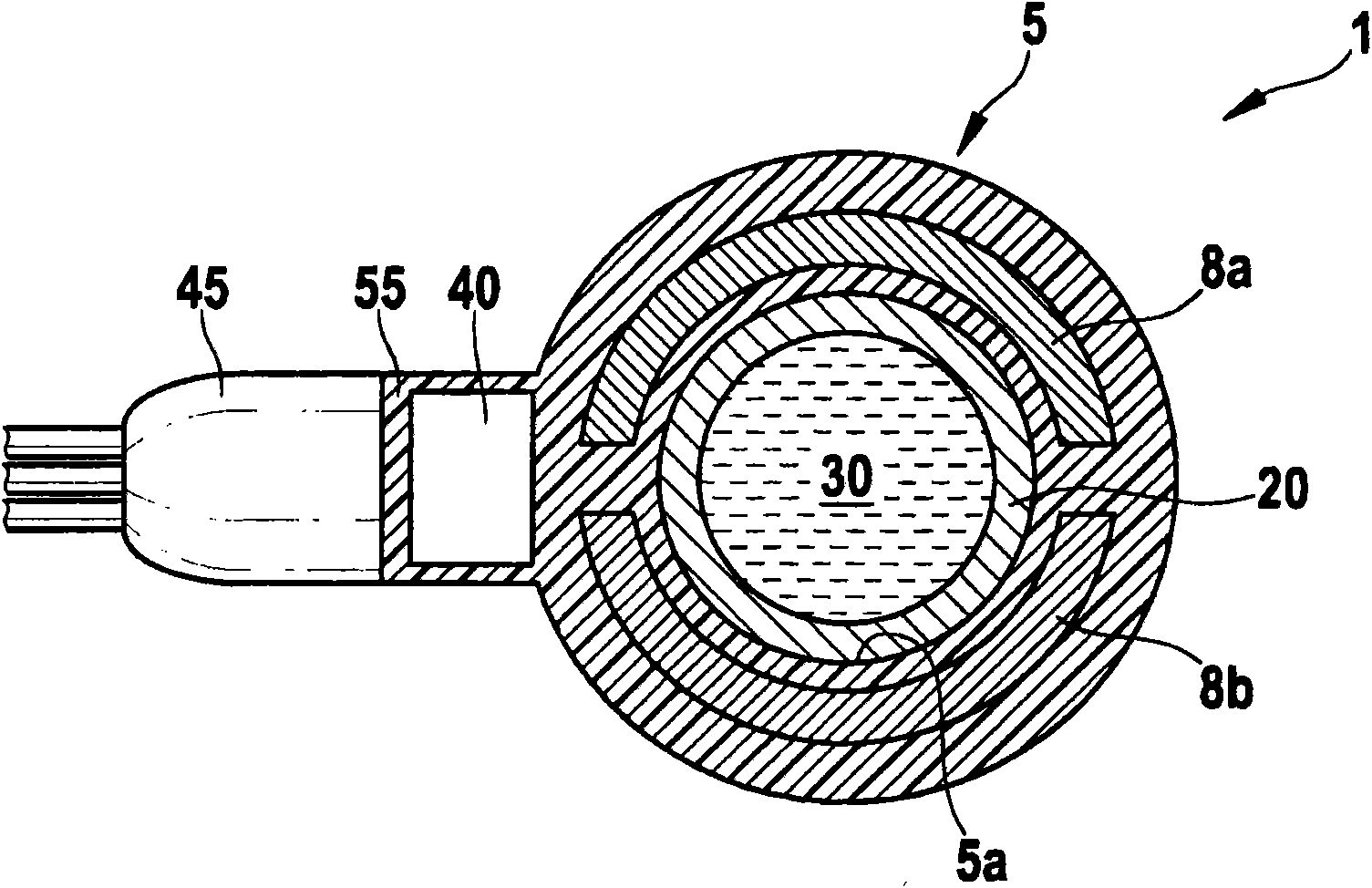

Method used

Image

Examples

Embodiment approach 1

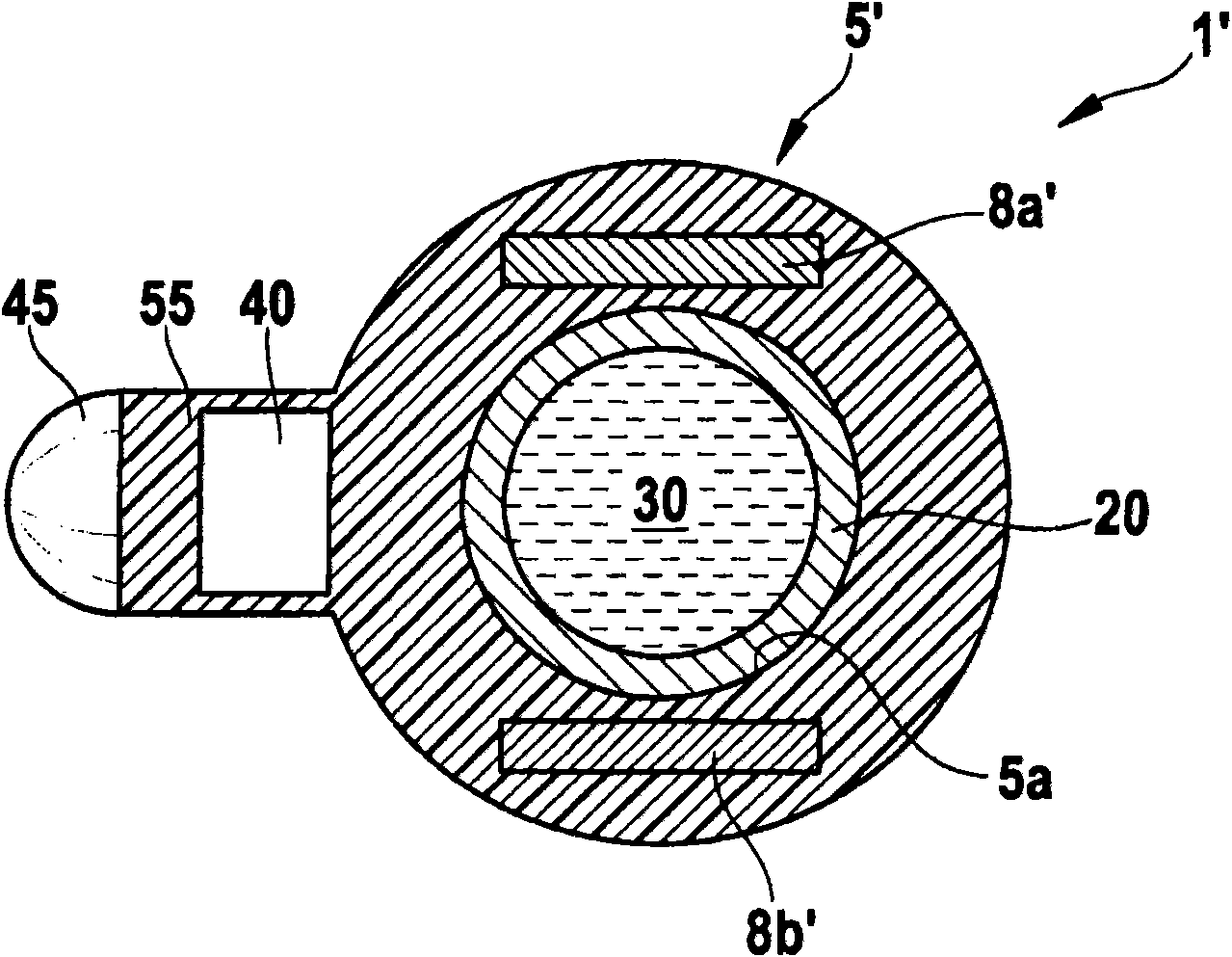

[0035] As in the second embodiment, the capacitor plates 8a", 8b" are arranged inside the casing 5", and also extend tangentially to the curvature of the cavity. In this embodiment, however, not the entire transverse direction of the fuel 30 The cross-section is between the capacitor plates 8a", 8b", but roughly two-thirds of the cross-section. This is due to the semi-cylindrical shell shape of the housing, but does not affect the quality of the measurement signal.

[0036] The projection 55 with the integrated evaluation circuit 40 and the plug device 45 arranged thereon is identical to that of the embodiment already described above.

[0037] Figure 4A schematic cross-sectional view of a fluid sensor device according to a fourth embodiment of the present invention is shown.

[0038] The fluid sensor device 1"' according to the fourth embodiment also has a housing 5"' in the form of a semi-cylindrical shell. It differs only from the third embodiment in that the capacitor pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com