Hydraulic machine

A machine and hydraulic technology, applied in the direction of machines/engines, mechanical equipment, hydroelectric power generation, etc., can solve problems such as unsatisfactory results, and achieve the effect of improving service life, high efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

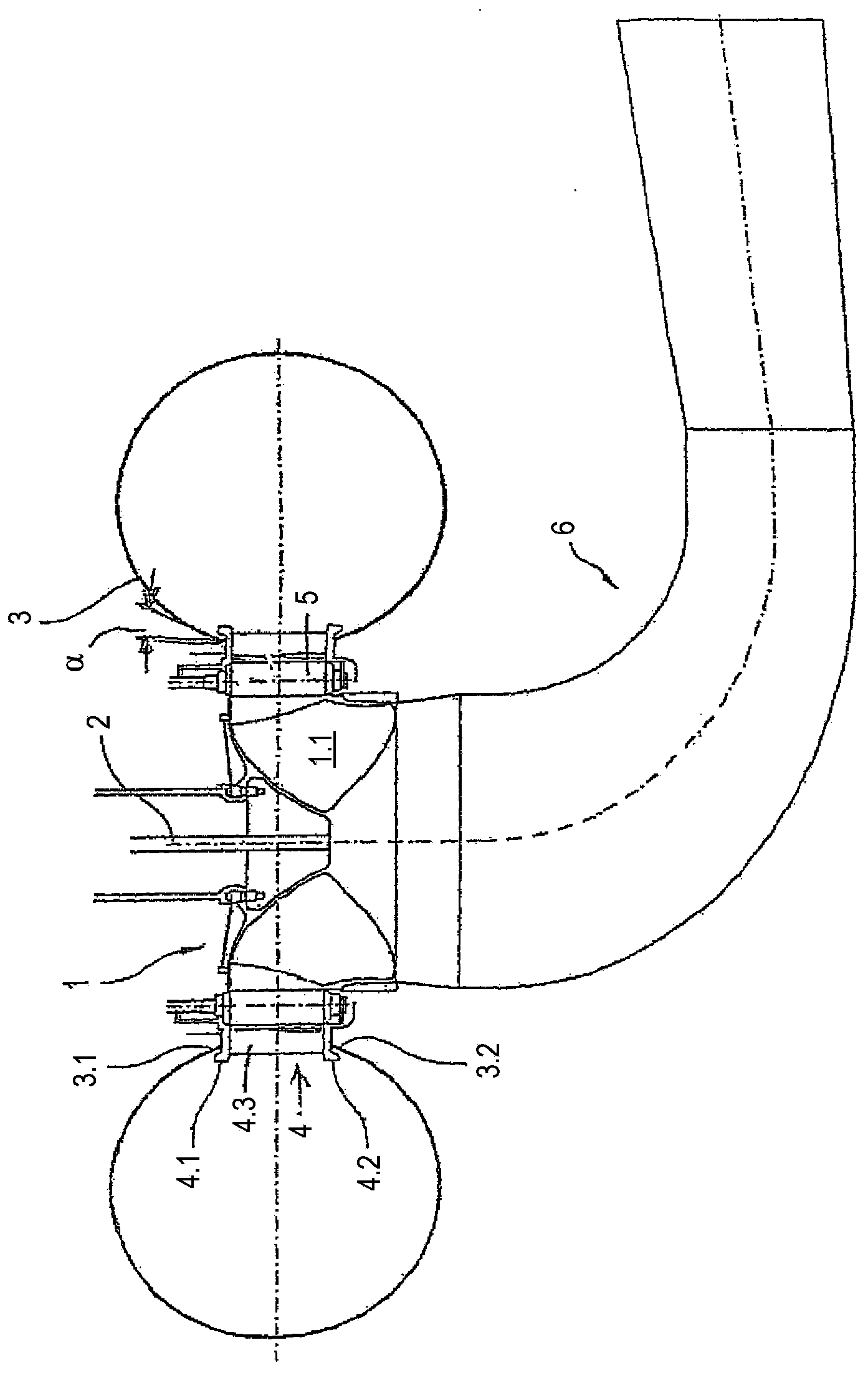

[0028] exist figure 1 The mixed flow turbine shown in has an impeller 1 . The impeller comprises a plurality of blades 1.1. The impeller 1 revolves around the axis of rotation 2 .

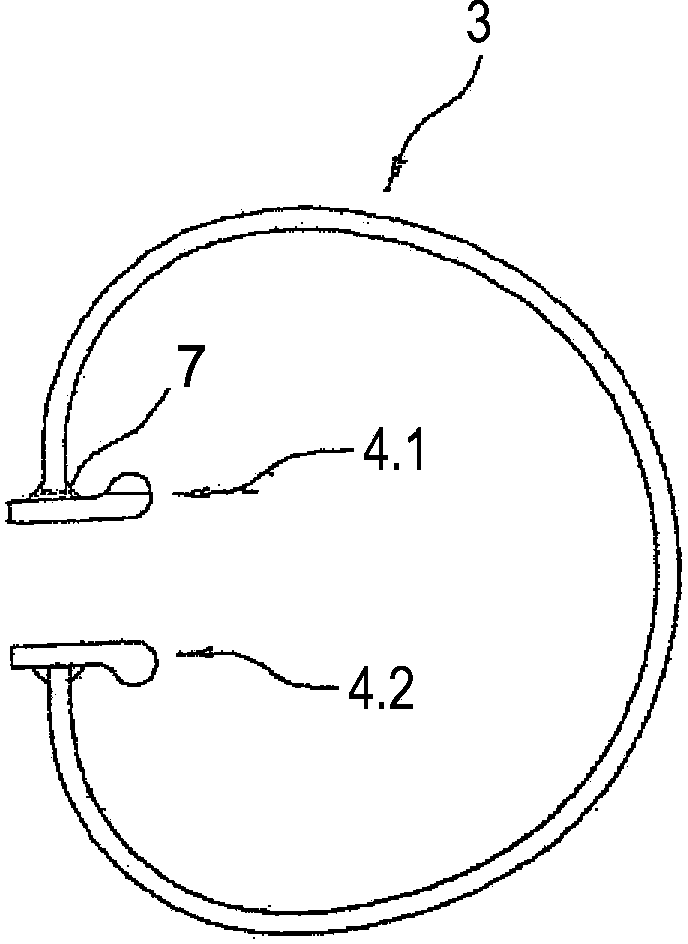

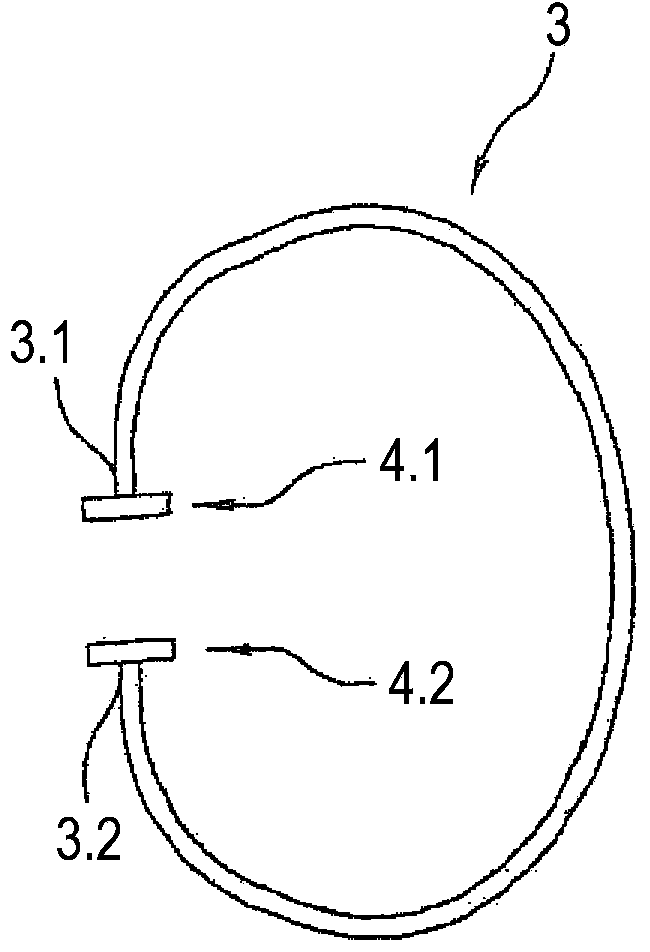

[0029] The impeller 1 is surrounded by a spiral housing 3 . The spiral housing 3 has, for example, a circular cross section. It has an annular groove-like opening towards the impeller 1 . The open groove is delimited by annular edges 3.1, 3.2.

[0030] The transverse ring 4 is connected to the annular groove formed by the edges 3.1, 3.2. The transverse ring has two transverse ring covers 4.1 and 4.2. The crossbeams 4.3 each serve as tie rods.

[0031] The region of the ring edges 3.1, 3.2 of the spiral housing is welded to the transverse ring cover 4.1, 4.2.

[0032] Between the transverse ring and the impeller, guides with guide vanes 5 are arranged.

[0033] Seen in the direction of flow, a suction pipe 6 is connected to the impeller 1 and has several sections.

[0034] As can be seen, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com