Anti-press drainage tube for urethral catheterization

A drainage tube and anti-pressure technology, applied in the direction of the catheter, etc., can solve the problems of poor liquid flow, easy to be crushed, needles falling off, etc., and achieve the effect of improving the degree of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

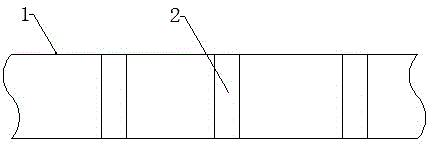

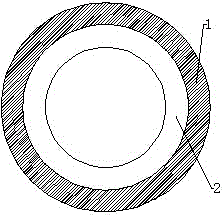

[0013] Example 1: An anti-pressure drainage tube for urinary catheterization, comprising a tube body 1, and anti-pressure rings 2 are arranged at intervals in the tube body 1 to improve the anti-pressure degree of the drainage tube, so as to prevent the drainage tube from being crushed, causing the medium in the tube to fail Smooth flow, the width of the anti-pressure ring 2 is five millimeters, the distance between the anti-pressure rings 2 in the pipe body 1 is five centimeters, and the anti-pressure ring 2 is integrally formed of polyvinyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com