Extracting tank with built-in partition plate

The technology of extraction tank and separator is applied in the field of pharmaceutical equipment, which can solve the problems of poor mixing effect and poor reflux mixing effect, and achieve the effect of strengthening extraction effect and good stirring and mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

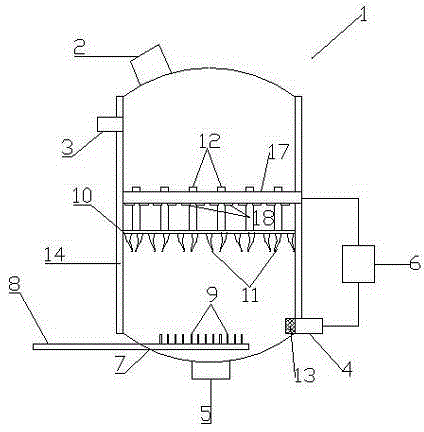

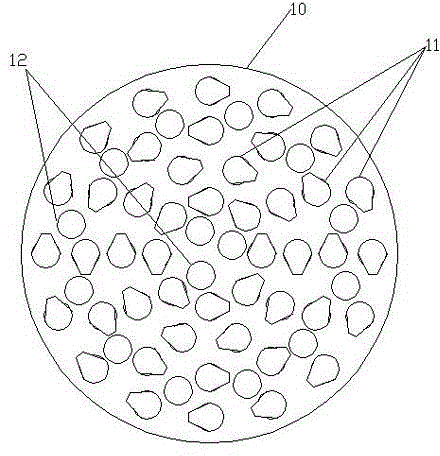

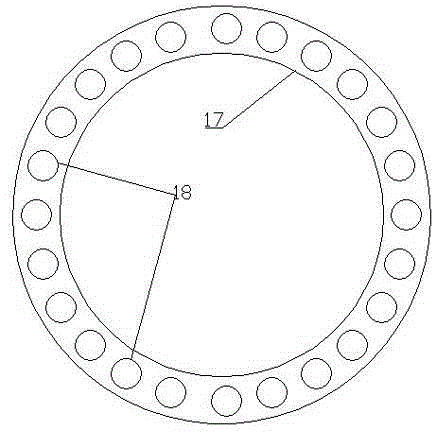

[0039] The extraction tank with built-in partition described in this embodiment is as figure 1 As shown, the tank body 1 is included, and the shape of the tank body 1 can be selected according to needs. In this embodiment, the tank body 1 is cylindrical. The upper part of the tank 1 is provided with a feed port 3, the top is provided with an air outlet 2, the bottom is provided with a slag outlet 5, and the lower part is provided with a liquid outlet 4 and an air inlet 7 (it can also be arranged at the bottom of the tank 1 ). The outer wall of the tank body 1 is provided with a heating interlayer 14, and the heating interlayer 14 can heat the tank body 1 through a built-in heating wire or passing steam into it. In this embodiment, the heating interlayer 14 is provided with There are heating wires (not shown in the drawings). Vent pipe 8, the vent pipe 8 stretches into the tank body 1 through the air inlet 7, and the connection between the vent pipe 8 and the air inlet 7 is a...

Embodiment 2

[0045] On the basis of the above-mentioned embodiment, this embodiment is such as Figure 4 As shown, a groove is provided along the inner wall of the tank body 1, and the partition 10 is embedded in the groove and is movably connected with it; the top of the partition 10 is provided with a rotating shaft 19 with a motor 20 for The partition plate 10 is controlled to rotate along the groove. Under the action of the motor 20, the rotating shaft 19 drives the partition plate 10 to rotate along the groove, so as to not only make the liquid medicine on the partition plate 10 more evenly distributed, but also play a good stirring and mixing effect on the liquid in the tank .

Embodiment 3

[0047] On the basis of the above examples, if Figure 5 As shown, the extraction tank described in this embodiment also includes a condenser 15 and a pressure relief pipe 16 with a pressure relief valve, the condenser 15 is provided with an inlet and an outlet, and the gas outlet 2 of the tank body 1 is connected to the The inlet of the condenser 15 communicates with the pressure relief pipe 16 , and the outlet of the condenser 15 communicates with the feed port 3 of the tank body 1 . When the pressure relief valve of the pressure relief pipe 16 is closed, the solvent vapor discharged through the gas outlet 2 is condensed and then returned to the tank for reuse through the feed port 3. On the one hand, the refluxed solvent after condensation can form a diluted solution locally. , can promote the rapid release of effective components in the medicinal materials. On the other hand, while the liquid in the tank is continuously recycled, the gaseous solvent is continuously replenis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com