Tft panel substrate inspecting device

A substrate inspection and panel technology, applied in the field of detector frames, to achieve the effects of reducing warpage, reducing part prices, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

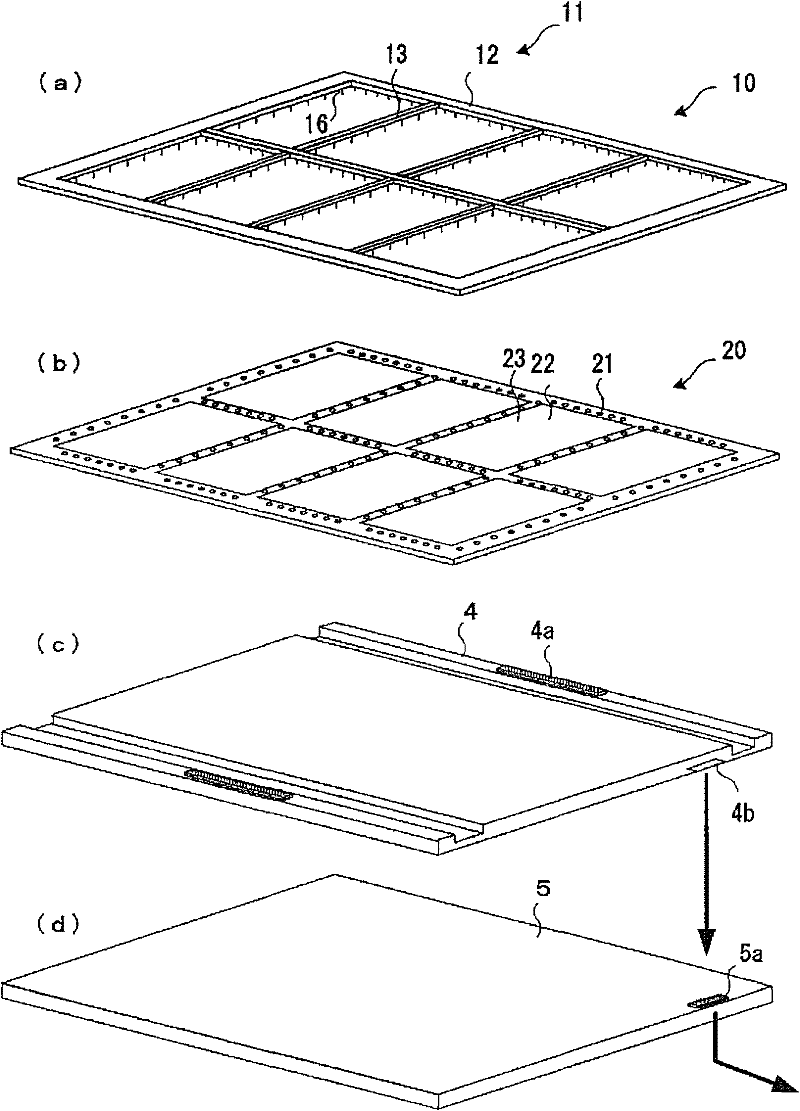

[0073] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described in detail.

[0074] figure 1 (a)-(d) is a figure for demonstrating the structure of the probe unit used for the TFT panel board|substrate inspection apparatus of this invention. Hereinafter, the case where a liquid crystal panel is used as a TFT panel substrate will be described as an example.

[0075] The liquid crystal panel 20 is an inspection object inspected by the TFT panel substrate inspection device 1 , and a TFT array 23 is formed on the TFT panel substrate 21 . The layout of the TFT array 23 formed on the TFT panel substrate 21 is variously set according to the size and specifications of the liquid crystal panel, for example. Thin film transistors are formed in a matrix in the TFT array 23 on the TFT panel substrate 21 , and signal electrode terminals (for example, scanning signal electrode terminals and video signal electrode terminals) for driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com