Vortex type compressor

A scroll compressor, rotating shaft technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., to achieve the effect of buffering impact, reducing noise, and reducing radial leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

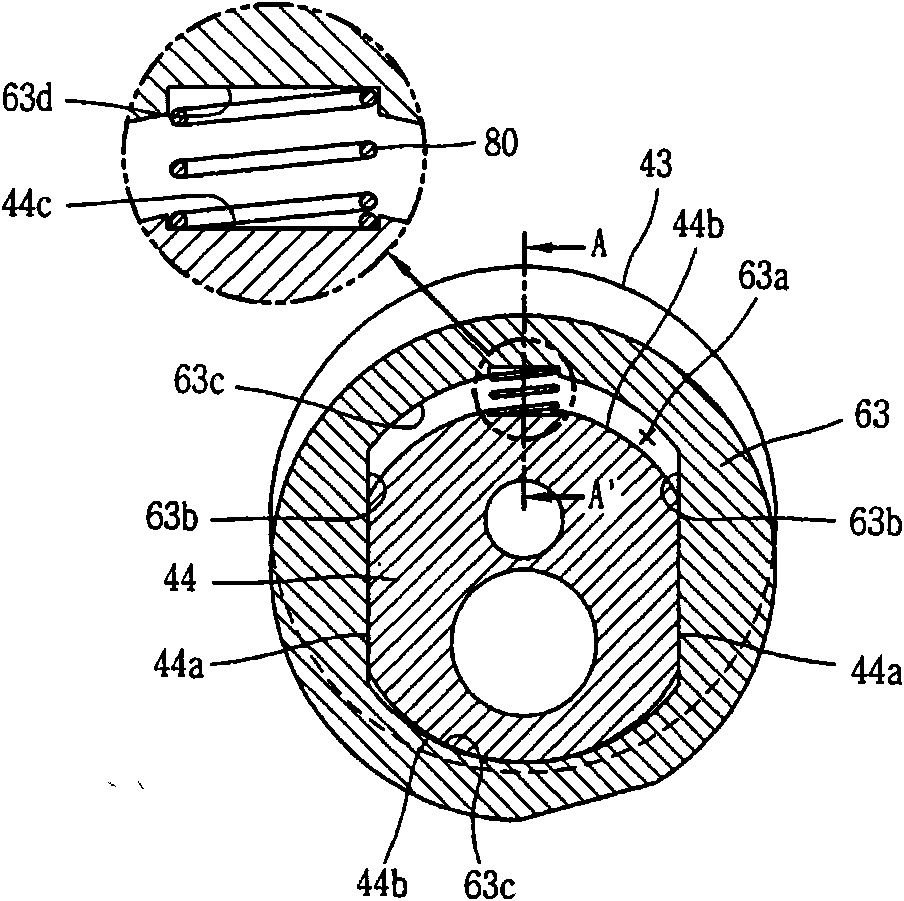

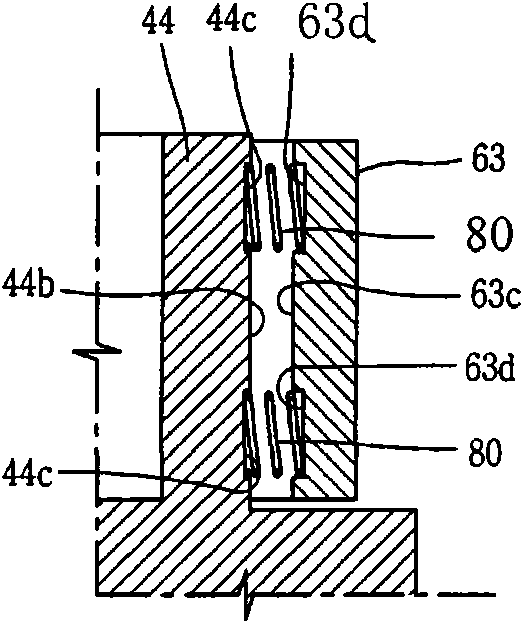

[0035] Hereinafter, an embodiment of the scroll compressor of the present invention will be described in detail with reference to the accompanying drawings.

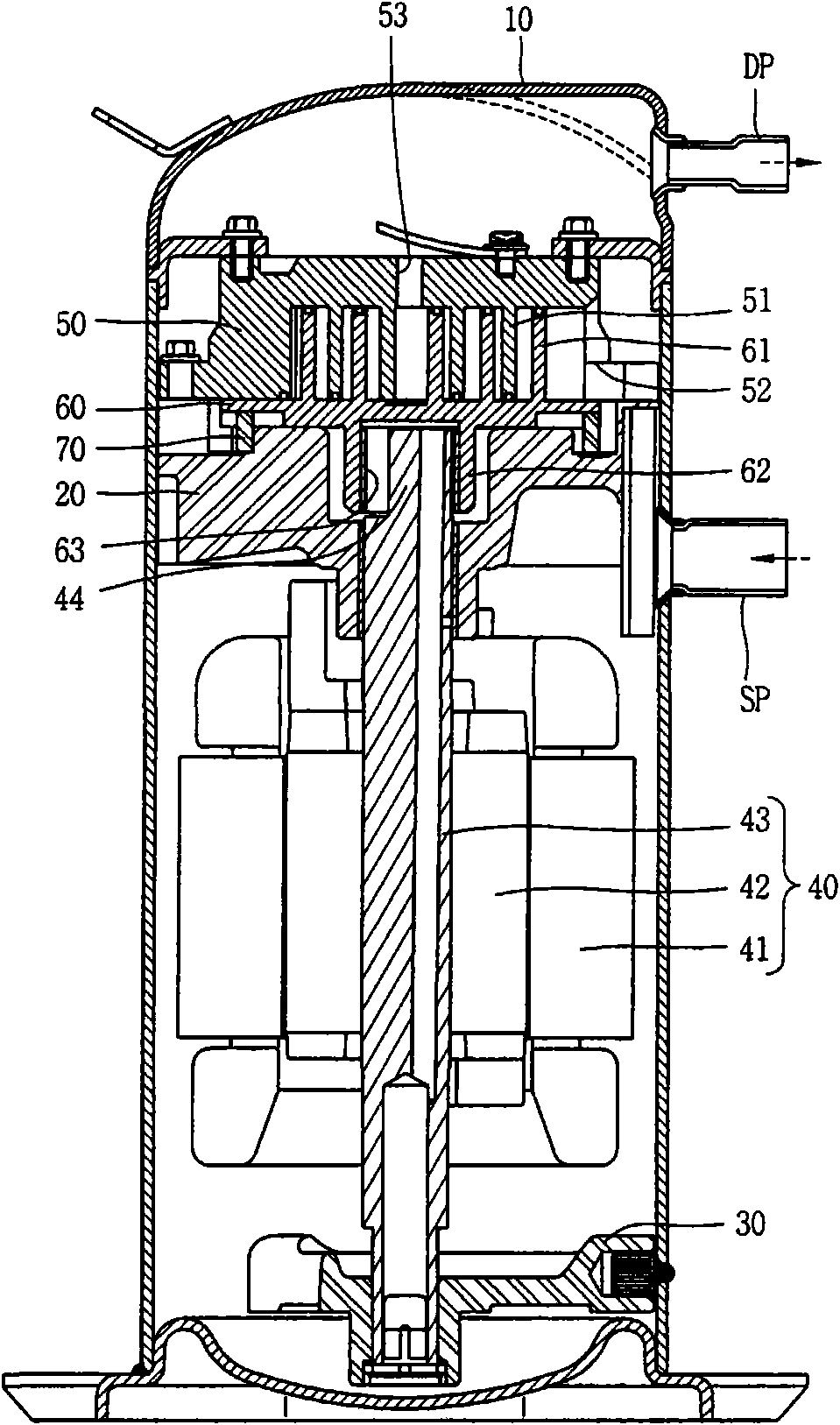

[0036] Such as figure 1 As shown, in the scroll compressor of the present invention, a main frame 20 and an auxiliary frame 30 are provided inside the airtight container 10 , and a motor mechanism unit 40 is provided between the main frame 20 and the auxiliary frame 30 . In addition, a compression mechanism unit combined with the motor mechanism unit 40 is provided on the upper side of the main frame 20 . The compression mechanism unit is composed of a fixed scroll 50 and a movable scroll 60 and can compress the refrigerant.

[0037] The motor mechanism unit 40 is composed of a stator 41 wound with a coil, a rotor 42 , and a rotating shaft 43 that is press-fitted into the center of the rotor 42 and transmits rotational force to the compression mechanism unit.

[0038] The upper end of the rotation shaft 43 is formed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com