Flue-cured tobacco rod pulling machine

A rod pulling machine and flue-cured tobacco technology, which is applied in the field of machinery, can solve the problems of shallow penetration of tooth nails, poor digging capacity, and laborious tooth nails, etc., and achieve the effect of less soil at the root, reasonable structural design, and avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

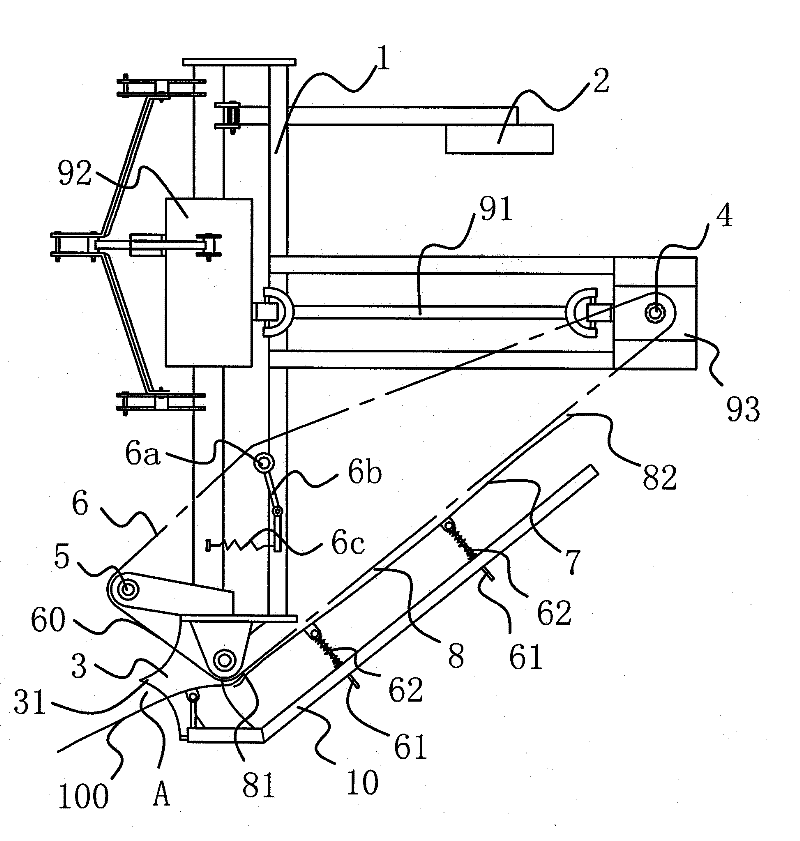

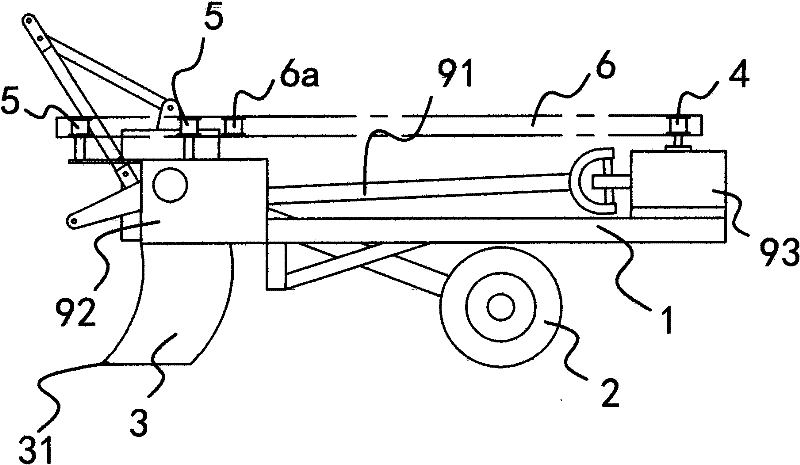

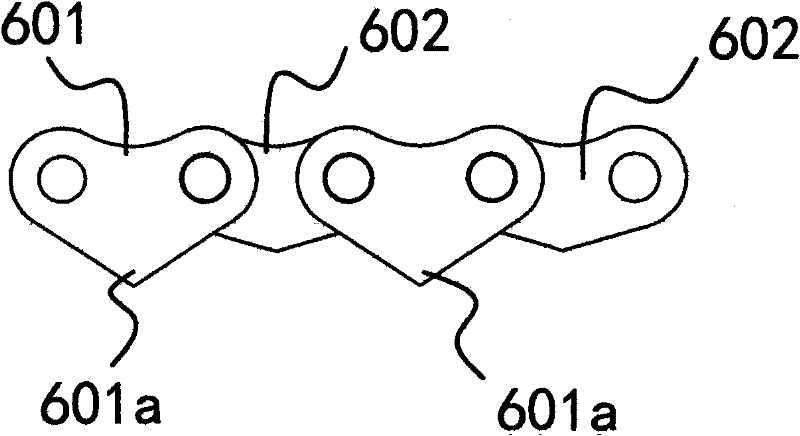

[0022] Such as figure 1 with 2 As shown, the flue-cured tobacco rod pulling machine includes a suspension frame 1, and a depth-gauge wheel 2 and a soil loosening shovel 3 arranged at the bottom of the suspension frame 1. The front end of the loosening shovel 3 has a tip 31, and the loosening shovel 3 is positioned at one side of the suspension frame 1, and the depth-gauge wheel 2 is positioned at the other side of the suspension frame 1. Also be provided with driving sprocket 4, guide sprocket 5, clamping chain 6 and clamping pressure plate 7 on suspension frame 1. The clamping chain 6 is annular and is inserted between the drive sprocket 4 and the guide sprocket 5 and meshes with the drive sprocket 4 and the guide sprocket 5 respectively. The drive sprocket 4 is connected with the power mechanism and the power mechanism can drive the drive sprocket 4 to rotate. The flue-cured tobacco rod pulling machine is usually hung on the rear of the tractor, and the rear power output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com