Photoelectric sensing type cavity observing window

A technology of photoelectric induction and observation window, which is applied in the field of cavity observation window, can solve problems such as increased maintenance difficulty, difficult cleaning, inconvenient assembly and disassembly of observation window seat, etc., to ensure uniformity and compactness, reduce maintenance time, and install Effects that are extremely easy to debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

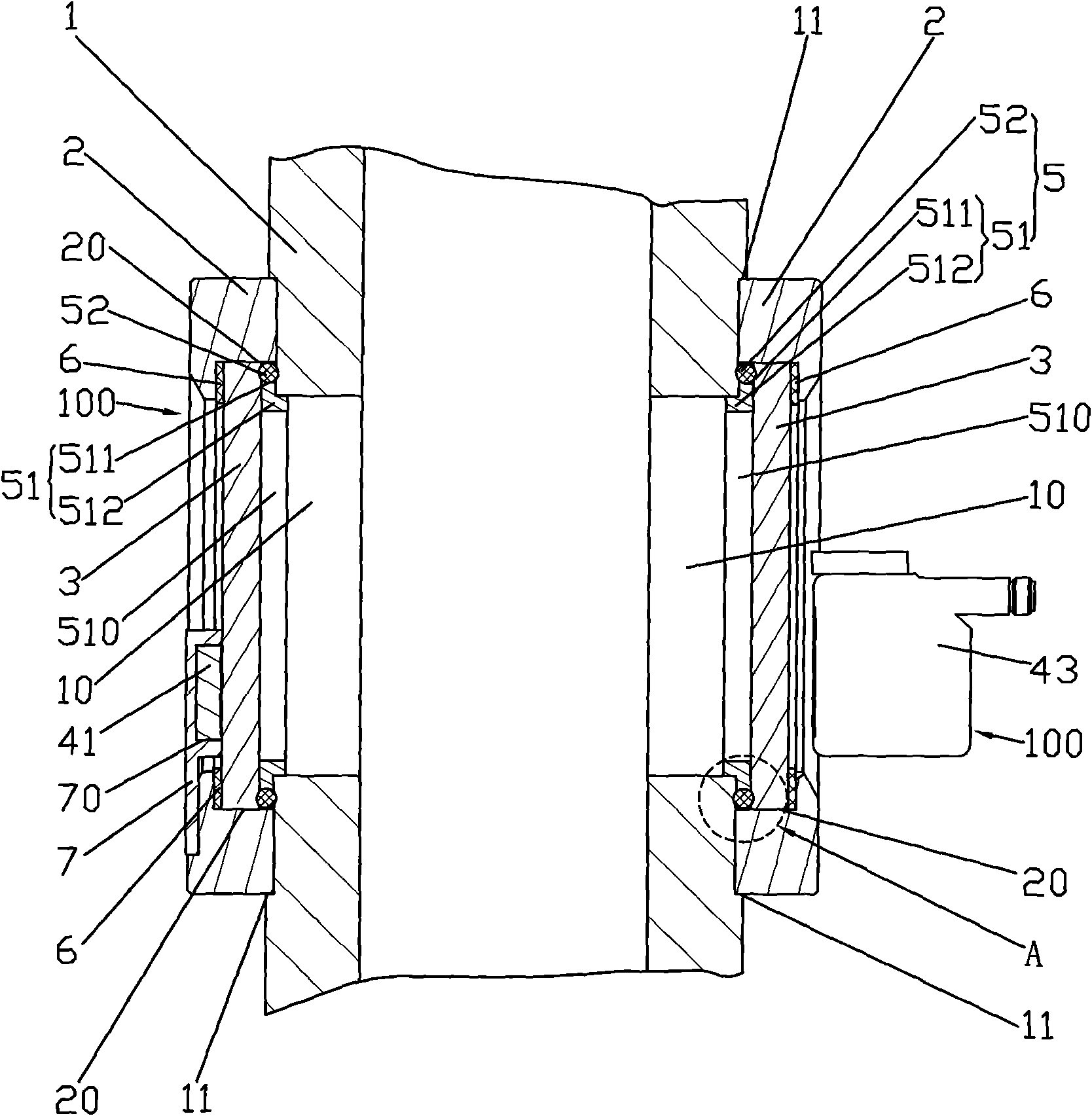

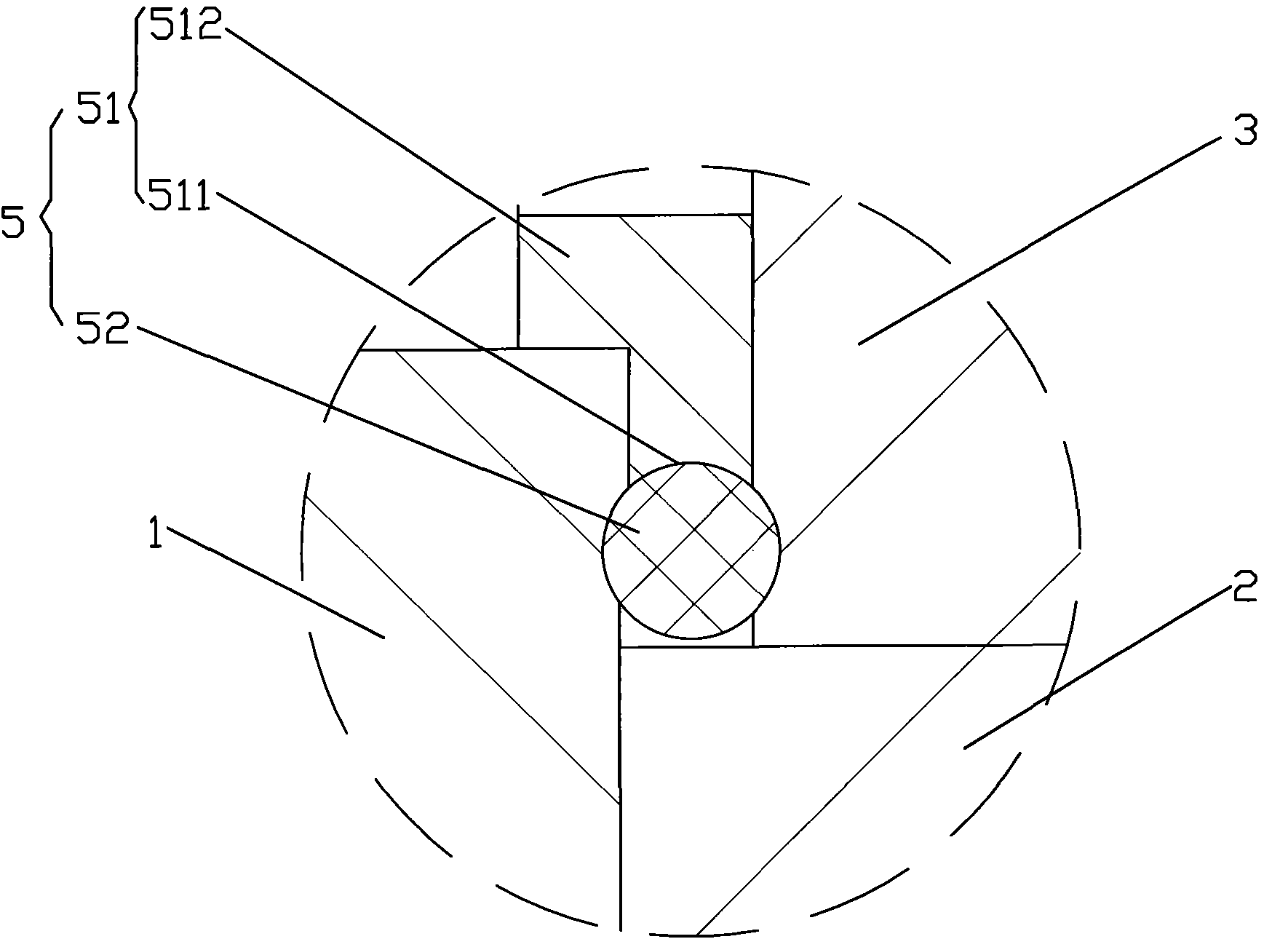

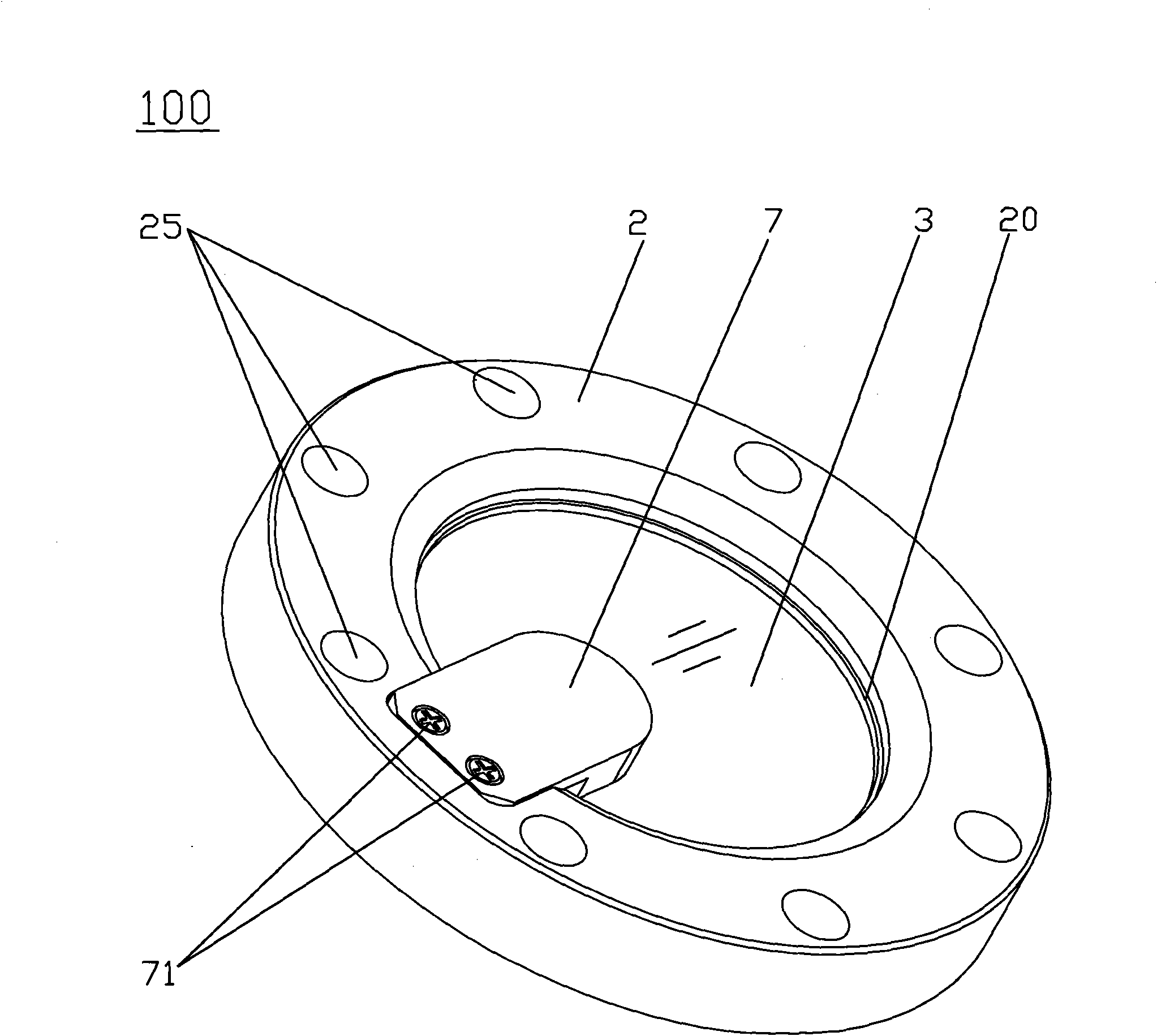

[0019] In order to describe in detail the technical content and structural features of the observation window of the photoelectric induction cavity of the present invention, further description will be made below in conjunction with the embodiments and accompanying drawings.

[0020] Such as figure 1 and image 3 As shown, the photoelectric induction cavity observation window 100 of the present invention is installed in the cavity 1 for coating. The photoelectric induction cavity observation window 100 includes a flange seat 2 , a sensor device and a glass plate 3 . The flange seat 2 is fixed on the cavity body 1 through mounting holes 25 and screws (not shown in the figure). The flange seat 2 has a hollow structure, and the hollow structure forms a receiving cavity 20 . The cavity 1 is provided with an observation channel 10 corresponding to the storage cavity 20 . The glass plate 3 is accommodated in the receiving chamber 20 and seals the observation channel 10 . Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com