Hydraulic excavator spiral bucket

A hydraulic excavator, screw-type technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of waste of energy, small capacity of single bucket, low efficiency of excavators, etc., to improve stability and reduce spilling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

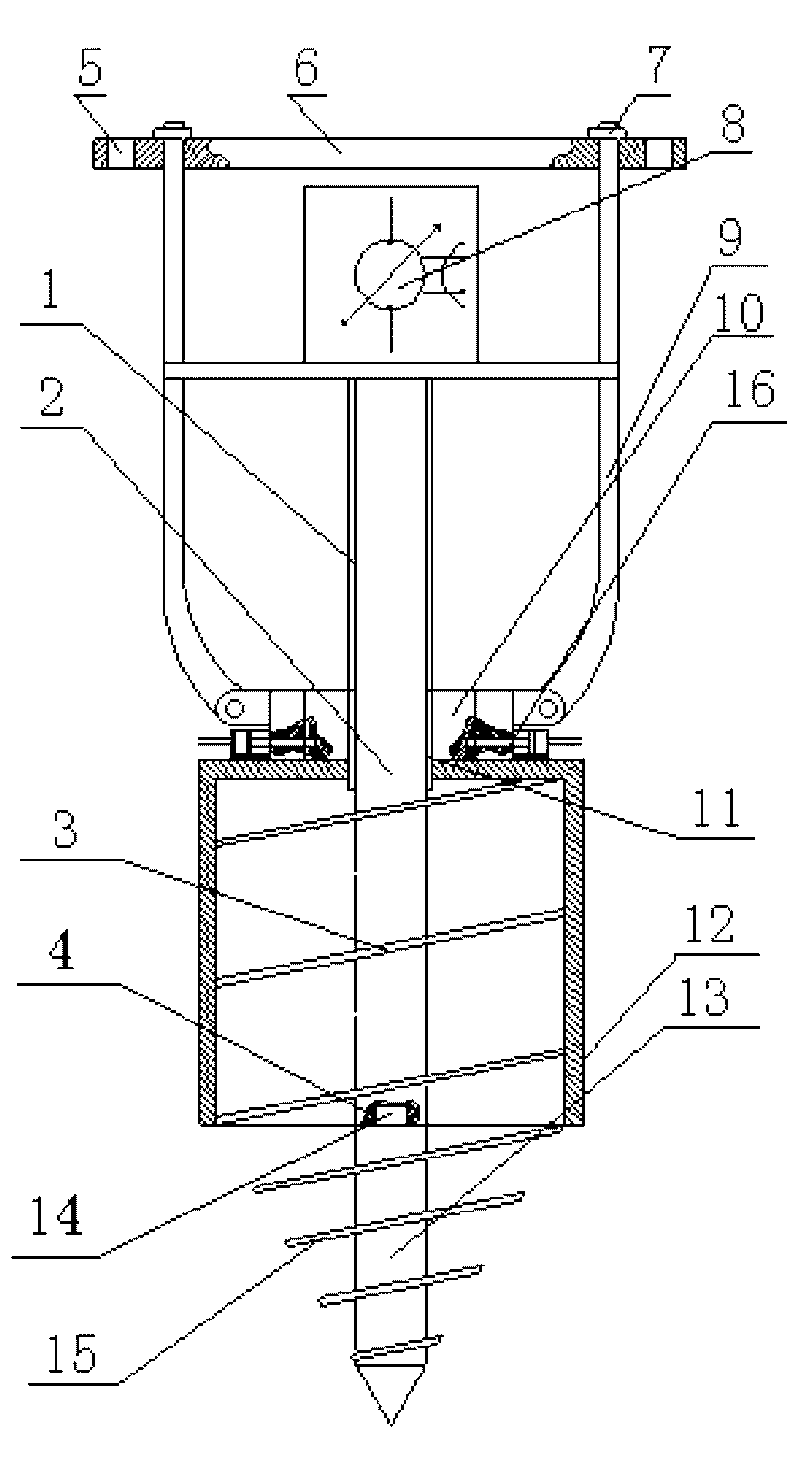

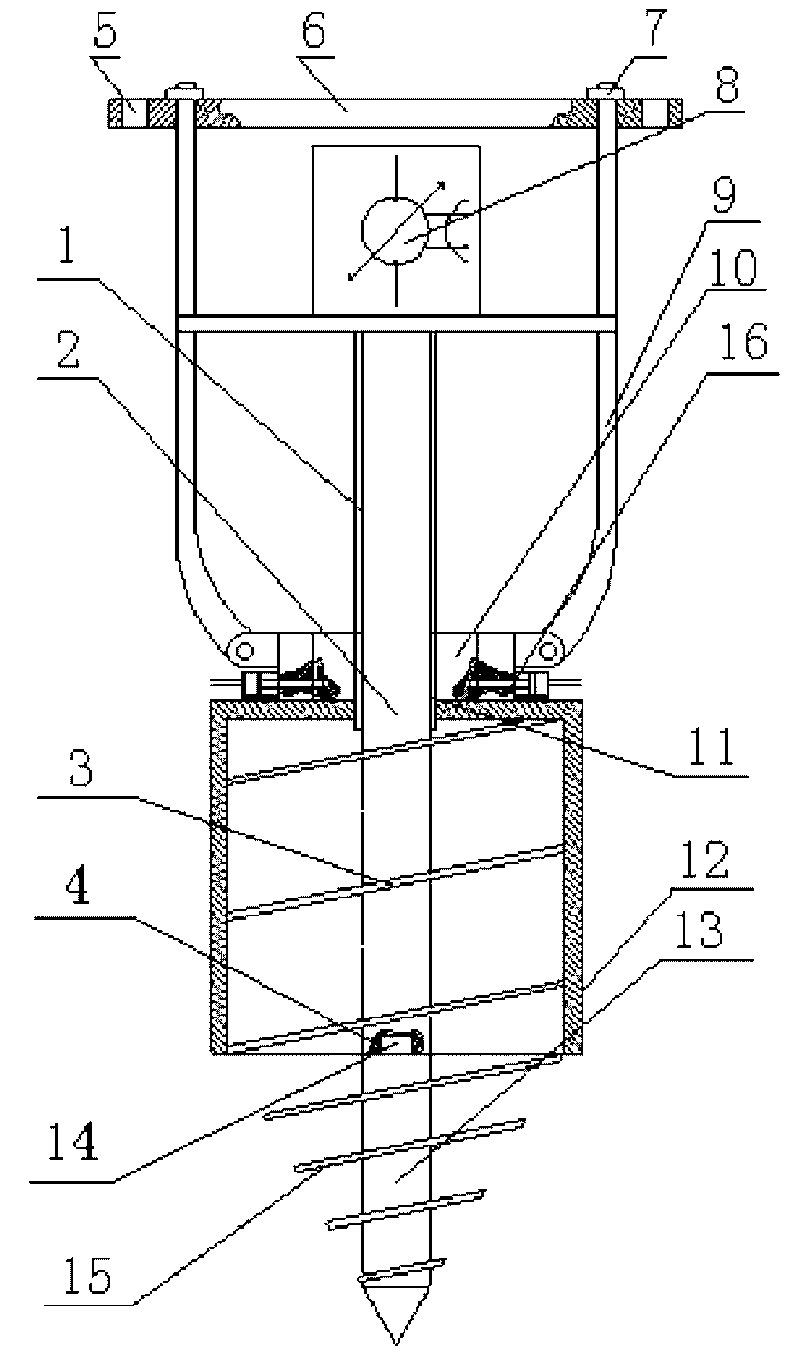

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Referring to the accompanying drawings, the present embodiment includes a storage tank 12 fixed on the guide column 9, a fixed top plate 6, the fixed top plate 6 and the two guide columns 9 are tightly connected by the fixing nut 7, and the extension arm of the excavator is fixed by The screw hole 5 on the top plate 6 is fixed on the fixed top plate 6, the storage barrel 12 is slidingly connected with the fixed sleeve 10 on its upper end, and a screw rod 2 driven by a variable hydraulic motor 8 is provided in addition, and the upper part of the screw rod 2 is provided with a fine thread 1, The lower part is provided with a large thread 3, the screw 2 passes through the storage barrel 12, and the upper fine thread 1 engages with the internal thread 11 of the fixed sleeve 10 at the upper end to realize the lifting of the screw 2, and the variable hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com