Furnace rotating support structure

A furnace body and support technology, applied in mechanical equipment and other directions, can solve the problems of low safety and reliability, poor practicability, and inconvenient installation, and achieve the effects of novel structure, good versatility and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention designs a structural form of a rotary support which is compact in structure, safe and reliable, good in versatility and convenient in installation, and is suitable for tilting melting, heat-holding furnace transfer and casting.

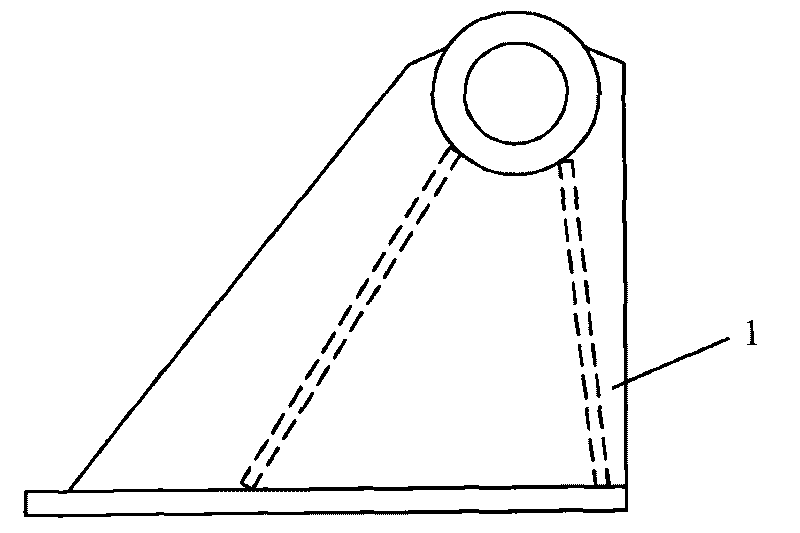

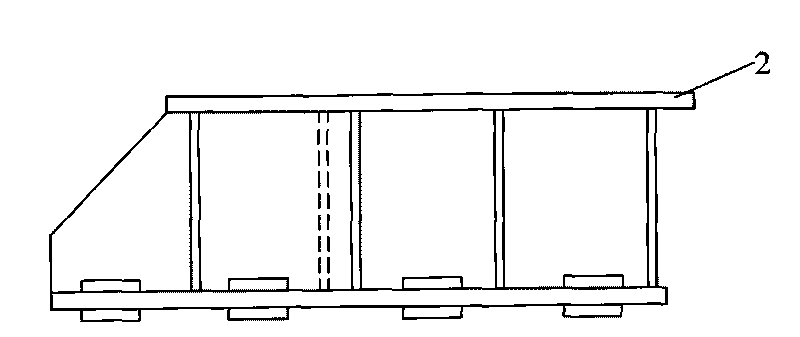

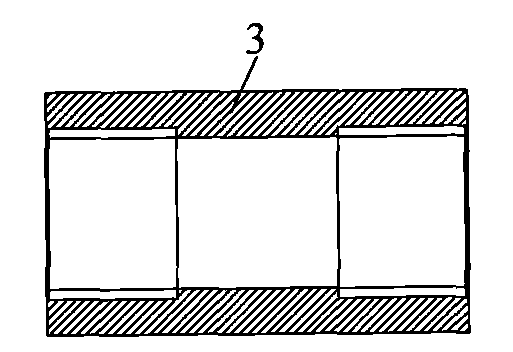

[0025] Such as Figure 1 to Figure 7 As shown, the structure of the rotary support of the furnace body includes an upper support 1, a lower support 2, a shaft sleeve 3, a rotating shaft 4, a self-lubricating shaft sleeve 5, a fixed stop sleeve 6 and a shaft end stopper 7, and the lower support 2 Bolt holes are opened on the bottom surface for connection with pre-embedded anchor bolts in civil engineering, long holes are opened on the upper surface of the lower support along the width direction, and long holes are opened on the bottom surface of the upper support along the length direction. The center and length of the long holes in the width direction The center of the long hole in the direction coincides, the upper support 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com