Device for cushioning automobile crash by tires

A technology of tires and automobiles, which is applied in the field of tire buffering car collision devices, which can solve problems such as cab flattening, threats to the lives of drivers and passengers, and lack of collision safety protection devices, so as to increase safety, improve personal safety, and protect society. Benefits and Significant Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

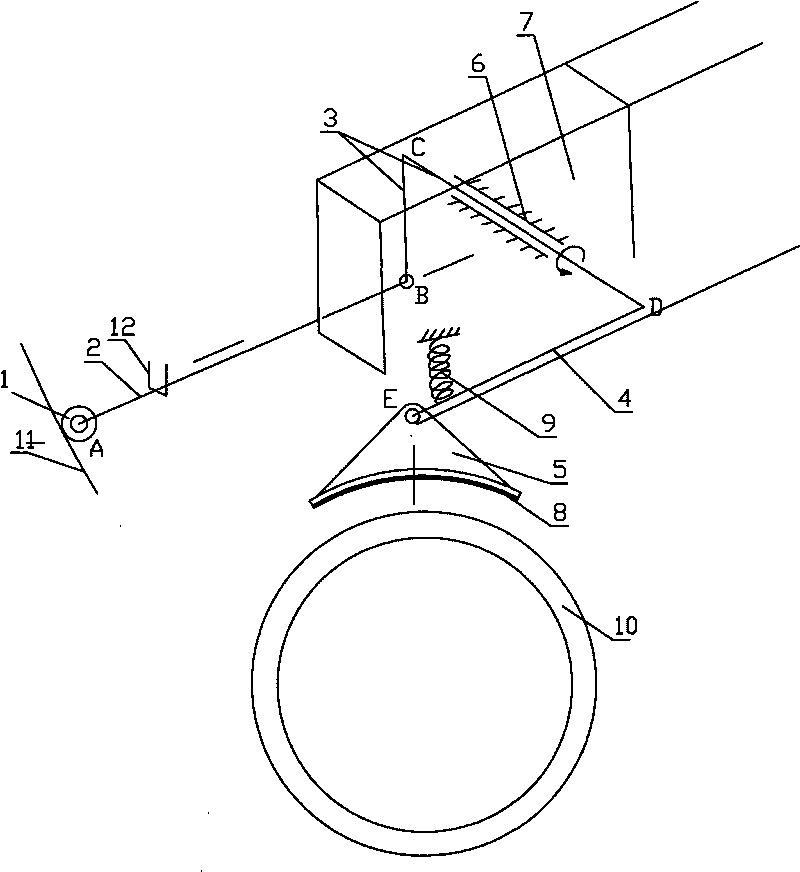

Embodiment 1

[0028] Specific examples of the present invention are attached figure 1As shown, including bumper 11, longitudinal beam 7 and tire 10, it is characterized in that: described longitudinal beam 7 is provided with a support sleeve 6, and " L " type swing bar 3 is housed in support sleeve 6, and its one end is connected with The push rod 2 is hinged, and the push rod 2 is connected with the positioning wheel 1 through the crane plant 12 fixed on the vehicle body, and the positioning wheel 1 is freely connected with the front bumper 11 of the vehicle; The splines are vertically connected, the ratio of the pressure rod 4 to the vertical rod B-C section of the "L" type swing rod 3 is 1 to 2, the pressure rod 4 is hung on the vehicle body through the spring 9, and is hinged with the pressure block 5, and the pressure is ensured. The centerline of the block 5 coincides with the circumferential centerline of the tread; the pressure block 5 is triangular, and the lower part is concave ar...

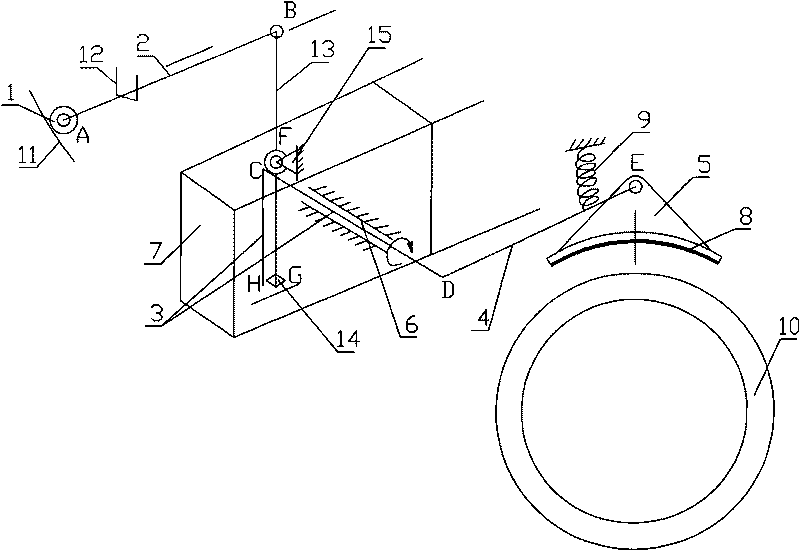

Embodiment 2

[0030] Specific examples of the present invention are attached figure 2 As shown, including bumper 11, longitudinal beam 7 and tire 10, it is characterized in that: described longitudinal beam 7 is processed with supporting point 15, and the middle part of straight swing bar 13 is hinged with supporting point 13, and its upper end is connected with push rod 2 The push rod 2 is connected with the positioning wheel 1 through the spider 12 fixed on the car body, and the positioning wheel 1 is freely connected with the front bumper 11 of the vehicle; there is a small baffle plate 14 at the lower end of the straight swing rod 13, and is mounted on the longitudinal The lower end of the "L"-shaped pendulum 3 in the supporting sleeve 6 on the beam 7 is freely connected; The ratio of the B-C section of the vertical bar of the bar 3 is 1 to 2, and the pressing bar 4 is hung on the vehicle body through the spring 9, and is hinged with the pressing block 5, and ensures that the center li...

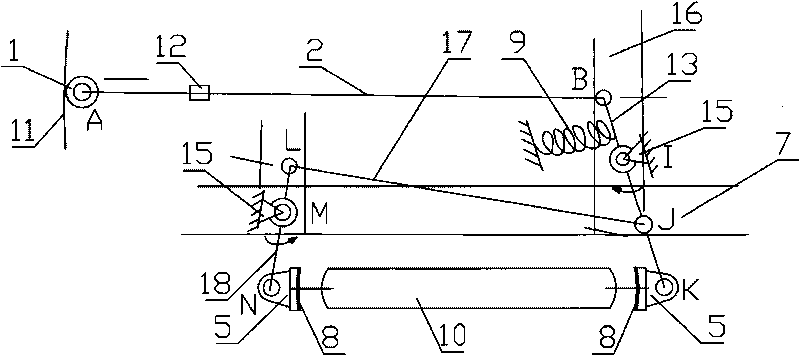

Embodiment 3

[0032] Specific examples of the present invention are attached image 3 Shown, comprise bumper 11, longitudinal beam 7, crossbeam 16 and tire 10; It is characterized in that described crossbeam 16 is processed with supporting point 15; One end is hinged with the push rod 2; the push rod 2 is connected with the positioning wheel 1 through the spider 12 fixed on the car body, and the positioning wheel 1 is freely connected with the front bumper 11 of the vehicle; the straight swing rod 13 passes through the spring mounted on the B-I section 9 is connected with the car body, and its other end is hinged with the briquetting block 5; one end of the middle push rod 17 is hinged at the middle part of the I-K section of the straight swing rod 13, and the other end is hinged with an end of the corresponding swing rod 18; the corresponding swing The rod 18 is hinged with the supporting point 15 mounted on the longitudinal beam 7, and the other end is hinged with the pressure block 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com