Novel hub motor driving system

A hub motor and drive system technology, which is applied in the direction of wheels, motion deposition, power devices, etc., can solve the problems of axle and chassis structure changes, occupying limited space on the inner wheels, and poor heat and heat dissipation effects, etc., so as to increase the service life and improve The cruising range and the effect of improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

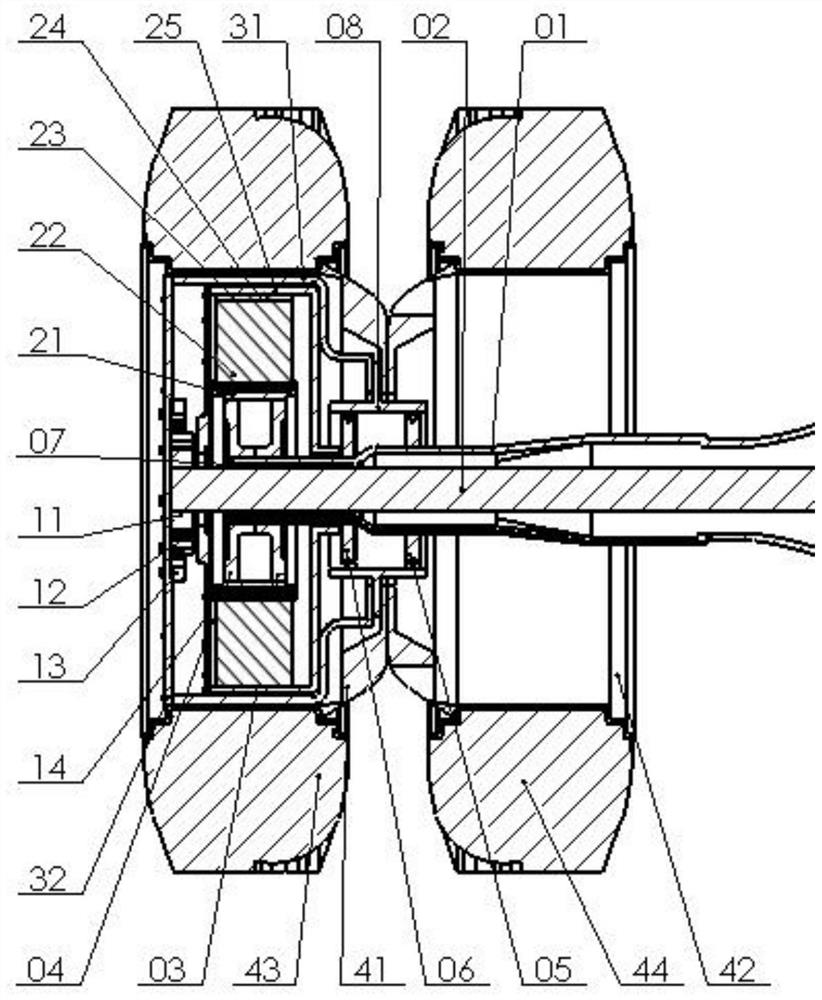

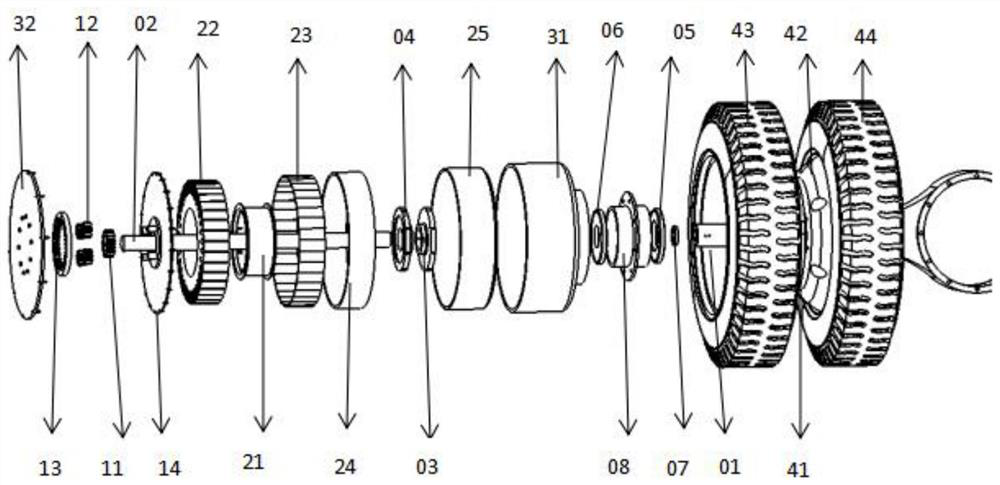

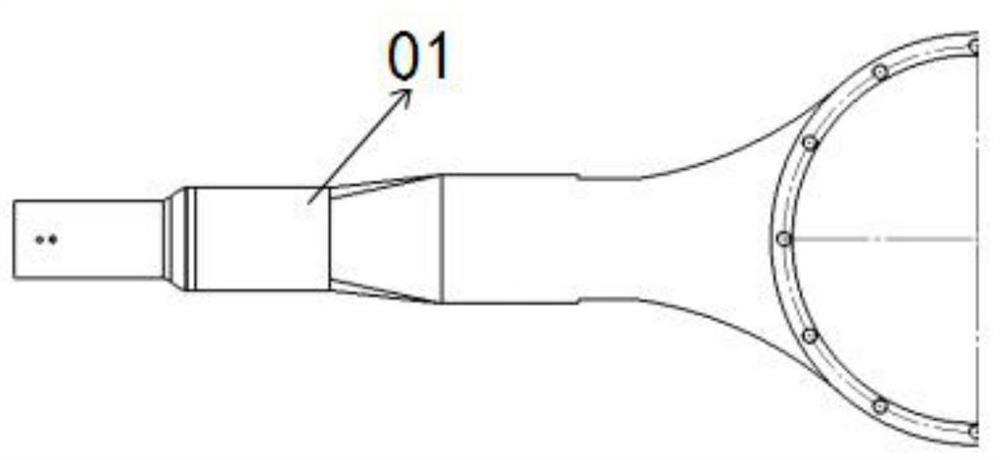

[0042] Such as Figure 1-14 As shown, this embodiment provides a new type of hub motor drive system, which can be used for hybrid or pure electric trucks, buses, engineering vehicles, etc., including hub motors, reducers, wheels and axle housings 01; hub motors and reducers are both Installed in the wheel, the axle housing 01 is located in the middle of the wheel; the hub motor is installed on the axle housing, the hub motor is connected to the reducer, and the outer side of the axle housing 01 is provided with a groove, which is used to allow the wire to pass through to supply power to the hub motor; the wheel rotates Installed on the axle housing 01, the reducer is connected to the wheels to drive the wheels to rotate; a half shaft is also rotated in the axle housing, one end of the half shaft is used to connect with the engine, and the other end passes through the axle housing to connect with the reducer.

[0043] In this embodiment, the in-wheel motor includes a sleeve 21, a...

Embodiment 2

[0054] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that the planetary gear reducer adopts a two-stage planetary gear reducer to perform two-stage reduction; specifically, the sun gear, planetary gear, ring gear and The planetary disc carrier is provided with two groups. The sun gear of the second-stage planetary gear is installed on the planetary disc carrier 14 of the first-stage planetary gear. After the planetary disc carrier 14 of the first-stage planetary gear is driven by the motor casing 25, it continues to drive The sun gear of the second-stage planetary gear realizes two-stage reduction; the planetary disc carrier of the second-stage planetary gear is fixedly connected with the motor casing 25 through bolts.

[0055] Further, the planetary gear reducer can also be provided with multiple stages as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com