Safety pressure-limiting valve

A pressure-limiting valve and safety technology, which is applied in safety valves, balance valves, valve devices, etc., can solve the problems that the pressure relief hole diameter cannot be enlarged, the pressure relief speed is not fast enough, and the control sensitivity is reduced, so as to achieve reliable performance, The effect of small working resistance and good control sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

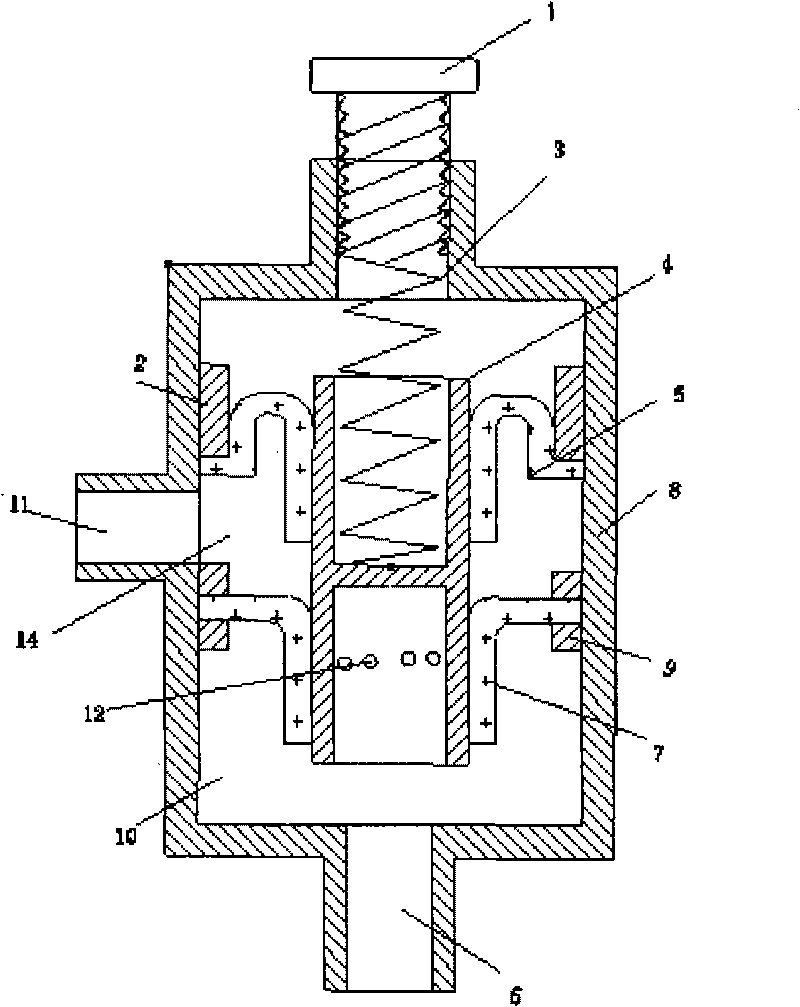

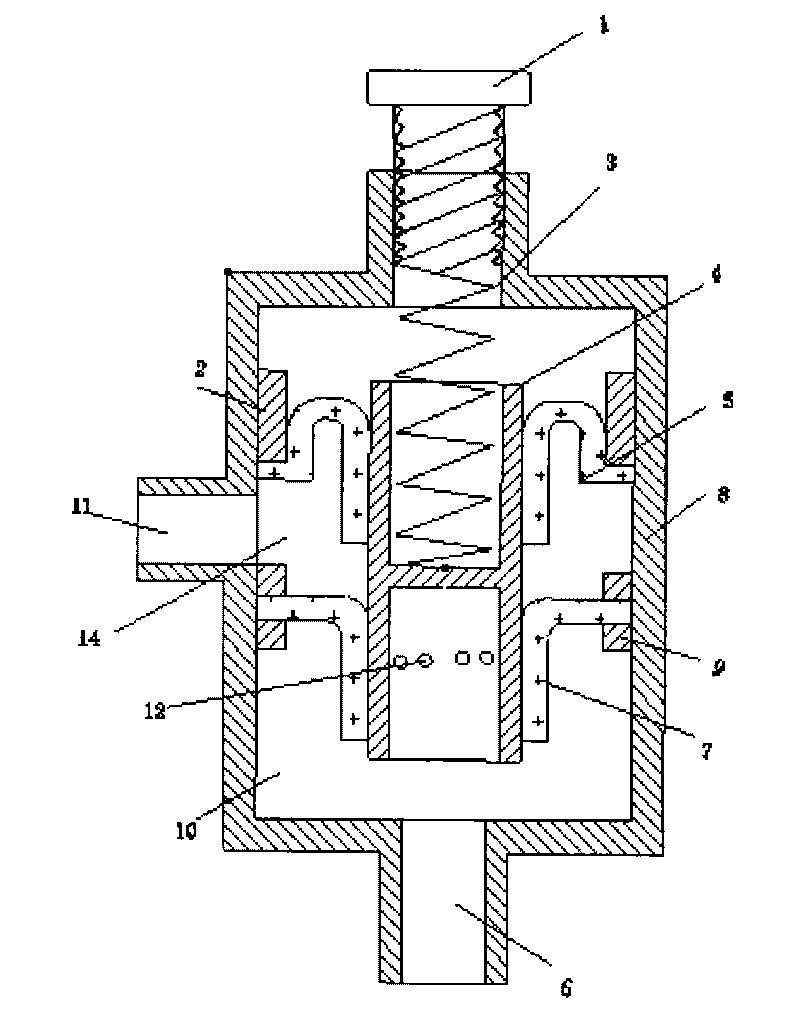

[0018] figure 1 It is a schematic cross-sectional structure of Embodiment 1; it includes a valve body 8 and a valve stem 4, and two upper and lower limit rings 2, 9 are built in. The valve stem 4 is placed in the valve body 8. The valve stem 4 is a cylindrical hollow body with a partition 13 inside, so that the hollow body is divided into an upper section and a lower section that are not connected to each other; The valve hole is 12, and there are two valve sleeves on the valve stem, that is, the sealing valve sleeve 5 and the opening and closing valve sleeve 7. The inner edges of the two valve sleeves are fixed on the periphery of the valve stem, and the outer edges of the valve sleeves are fixed on the valve body. around the cavity wall. The outer edge of the valve sleeve is sealed by limit rings 2 and 9, and an output chamber 14 is formed between the two valve sleeves to connect with the output port 11. The opening and closing valve sleeve 7 forms an input cavity 10 with ...

Embodiment 2

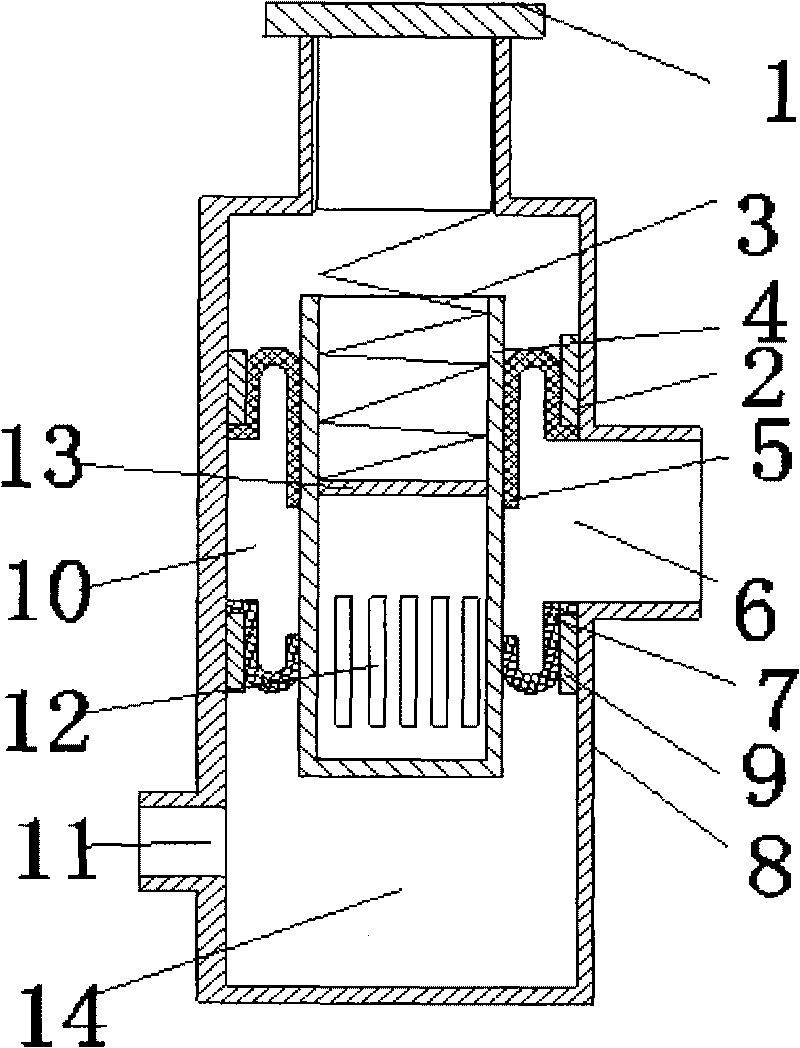

[0024] figure 2 It is a schematic diagram of the cross-sectional structure of the second embodiment. Including the valve body 8 and the valve stem 4, the upper and lower limit rings 2 and 9 are arranged inside the valve body 8. The valve stem 4 is placed in the valve body. The valve stem 4 is a cylindrical hollow body with a partition 13 inside, so that the hollow body is divided into an upper section and a lower section that are not connected to each other; 12. The valve hole is designed as a long row of holes. Two valve sleeves are arranged on the valve stem, that is, the sealing valve sleeve 5 and the opening and closing valve sleeve 7, and the inner edges of the two valve sleeves are all affixed to the periphery of the valve stem 4. The outer edge of the valve sleeve is all fixedly connected to the periphery of the inner cavity wall of the valve. The outer edge of the valve sleeve is sealed with upper and lower limit rings 2 and 9 respectively. An input cavity 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com