Foam gun

A foaming gun and valve core technology, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of increasing cost, failing to meet sealing requirements, difficult to clean, etc., to improve the amount and quality of foaming, prolong Effect of improving service life and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

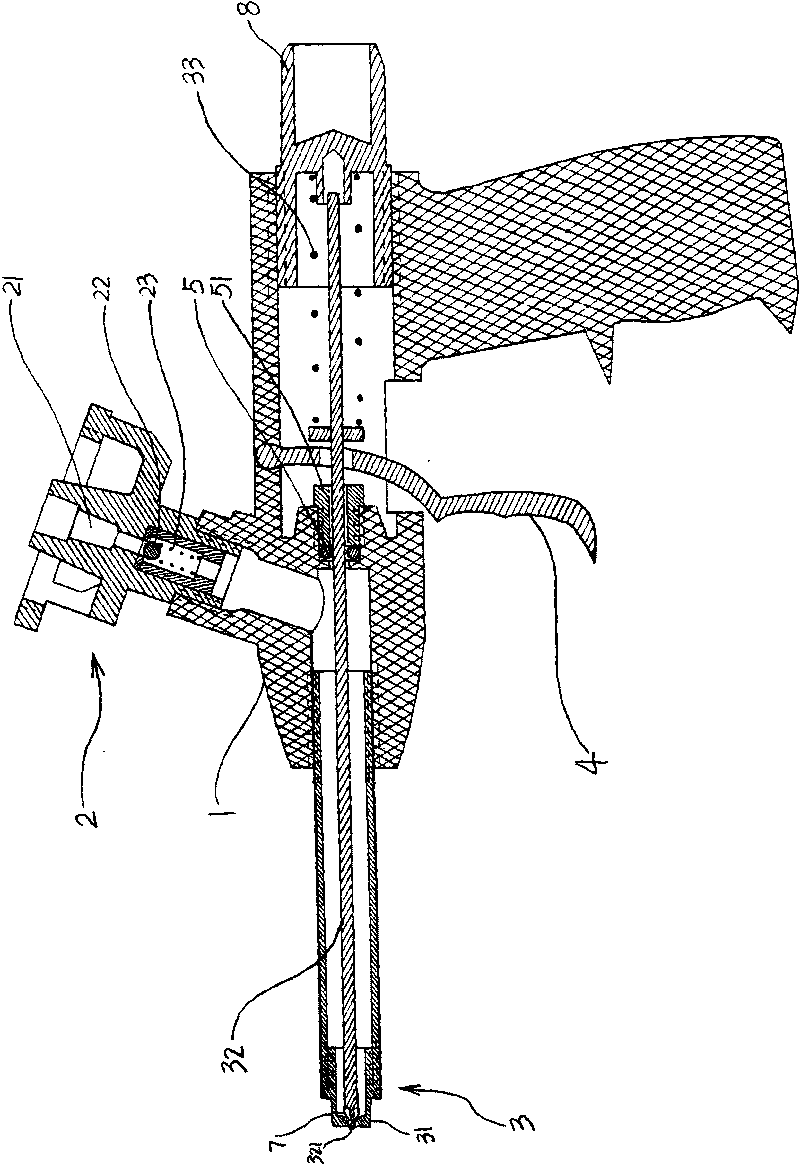

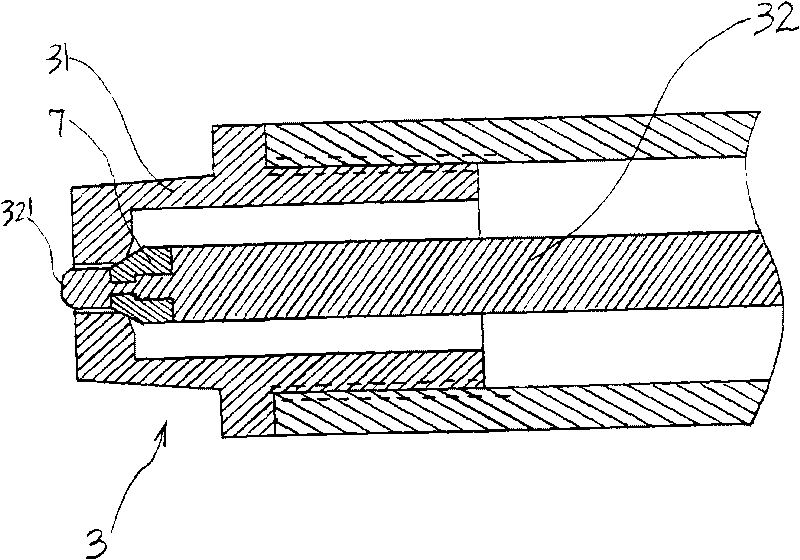

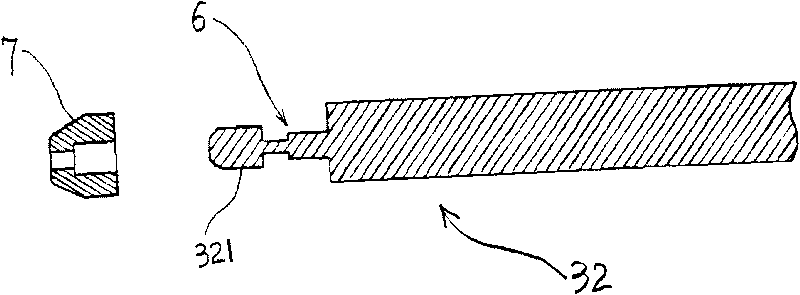

[0030] Foaming gun of the present invention, it comprises gun body 1, liquid inlet valve 2, liquid outlet valve 3 and switching device 4, and liquid outlet valve 3 comprises liquid outlet nozzle 31, valve core 32 and back-moving spring 33, and switching device 4 can make The liquid outlet valve 3 is opened or closed, for example, the valve core 32 has at least a part of the inner channel extending out of the foaming gun, so that the switch device 4 can directly or indirectly act on the valve core 32, wherein on the valve core 32 The sealing ring 7 made of metal material is set to seal with the liquid outlet nozzle 31, which effectively prevents and avoids the leakage and / or solidification of the foam caulking agent in the foaming gun, and effectively prevents the channel from being blocked , effectively preventing and avoiding the danger of leakage or burning or explosion of the foam caulk or gas in the foaming gun, improving the wear resistance, sealing and stability of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com