Method for producing white wine by distilled grain continuous solid state fermentation

A technology for solid-state fermentation and liquor, which is applied in microorganism-based methods, biochemical equipment and methods, and preparation of alcoholic beverages. , The ratio is scientific and reasonable, and the effect of improving the alcohol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Raw materials and equipment:

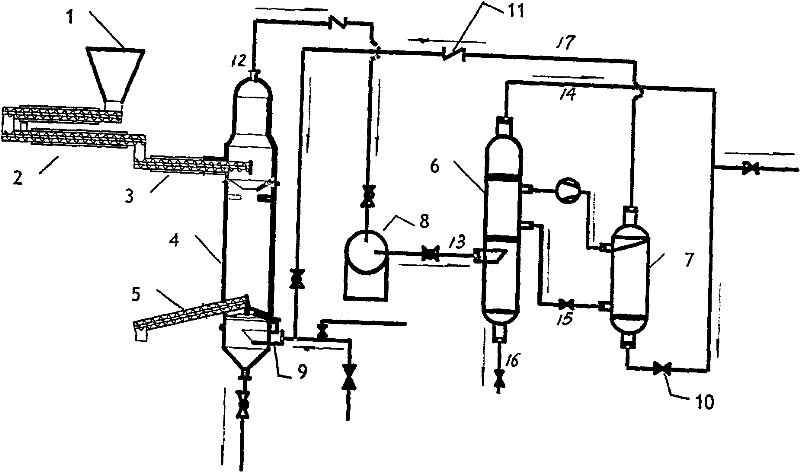

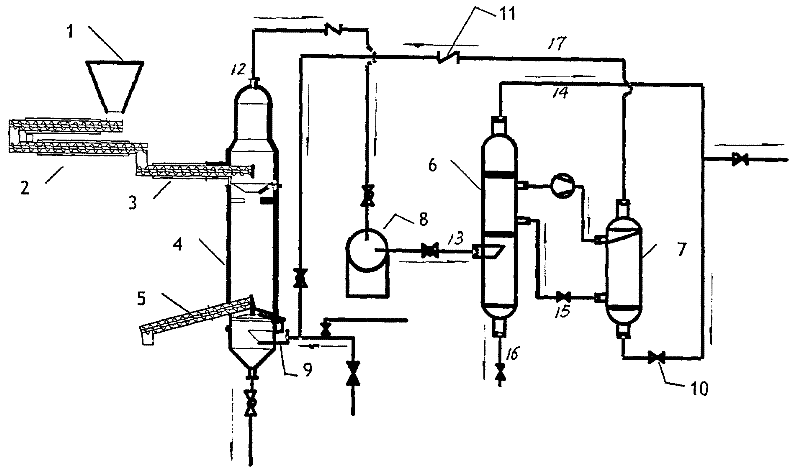

[0054] 1. Equipment: "Continuous solid-state fermentation and product gas stripping heat pump coupling and separation equipment" designed and provided by the Institute of Process Engineering, Chinese Academy of Sciences.

[0055] The specifications and functions of the key components used in the equipment are:

[0056] 1) Second-level mixing conveyor: specifications Ф1m×20m, for mixing waste and compound bacterial liquid, and performing preliminary saccharification and enzymatic hydrolysis;

[0057] 2) Three-stage conveyor: Ф1m×30m in size, for enzymatic hydrolysis of dross saccharification;

[0058] 3) Fermentation and separation tower: Specifications: Ф3m×30m, effective size Ф3m×28m, for inoculation fermentation and carbon dioxide extraction of waste fermentation products;

[0059] 2. Raw and auxiliary materials:

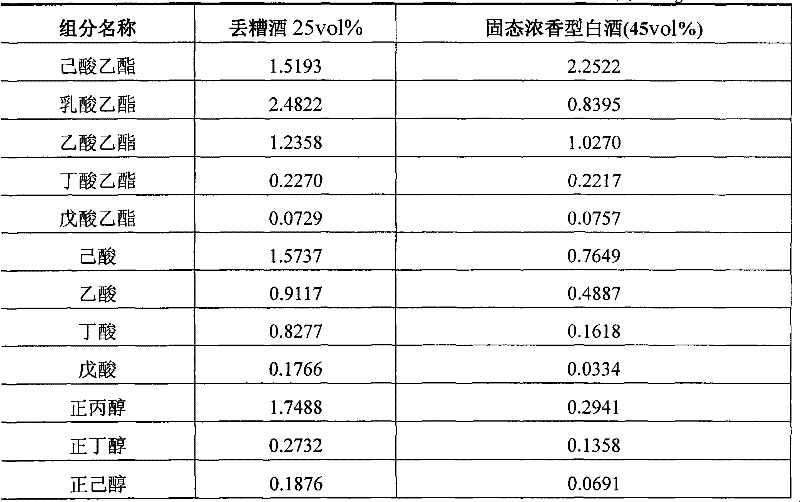

[0060] Lost grains: it is the normal fermented grains of Luzhou-flavor solid-state liquor, with a pH value of 3.0 and...

Embodiment 2

[0079] (1) Raw and auxiliary materials and equipment:

[0080] 1. Equipment

[0081] The equipment is the same as in Example 1, and the specifications of the key components are as follows:

[0082] 1) Secondary mixing conveyor: specification Ф1.2m×18m;

[0083] 2) Three-stage conveyor: specification Ф1.2m×35m;

[0084] 3) Fermentation separation tower: specification: Ф3m×35m, effective size Ф3m×30m;

[0085] 2. Raw and auxiliary materials

[0086] Discarded grains: normal fermented distilled grains for Maotai-flavored liquor solid liquor, with a pH of 4.5 and a moisture content of 67%;

[0087] Glucoamylase: commercially available product, enzyme activity: 125,000 U / g;

[0088] Active dry yeast: commercially available active dry yeast for liquor, with a viable cell rate of 98%;

[0089] Composite cellulase (food grade): commercially available product, its filter paper FPA is 40,000 u / g;

[0090] Carbon dioxide: commercially available food grade, with a purity of 99.9%.

...

Embodiment 3

[0105] (1) Raw and auxiliary materials and equipment

[0106] 1. Equipment

[0107] Equipment and specification thereof are with embodiment 1.

[0108] 2. Raw and auxiliary materials:

[0109] Digging grains: it is normal distilling grains fermented by Fen-flavor solid liquor, with a pH value of 3.5 and a water content of 55%;

[0110] Glucoamylase: commercially available product, enzyme activity: 125,000 U / g;

[0111] Active dry yeast: commercially available active dry yeast for liquor, with a viable cell rate of 99%;

[0112] Composite cellulase (food grade): commercially available product, its filter paper FPA is 40,000 u / g;

[0113] Carbon dioxide: commercially available food grade, with a purity of 99.5%.

[0114] (2) Process:

[0115] 1. Preparation of compound bacterial liquid: Mix commercially available glucoamylase, compound cellulase and dry yeast according to the weight ratio of 3:2:5 to form a compound starter, then add 35°C warm water with a weight percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com