Water-based paint grinding system with cycle hedge function

A water-based coating and functional technology, applied in the field of grinding system, can solve the problems of weak pertinence, achieve the effect of secondary grinding fine, increase the number of collisions, and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below according to the drawings and embodiments.

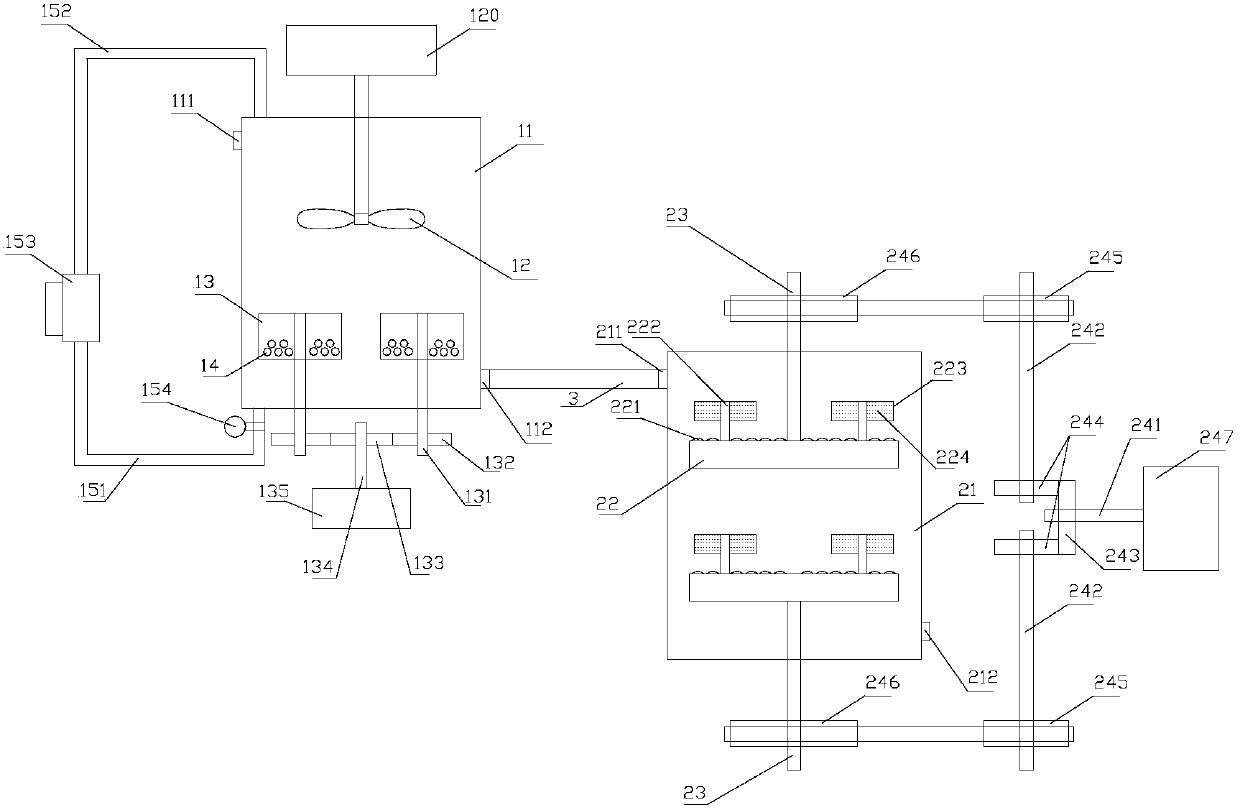

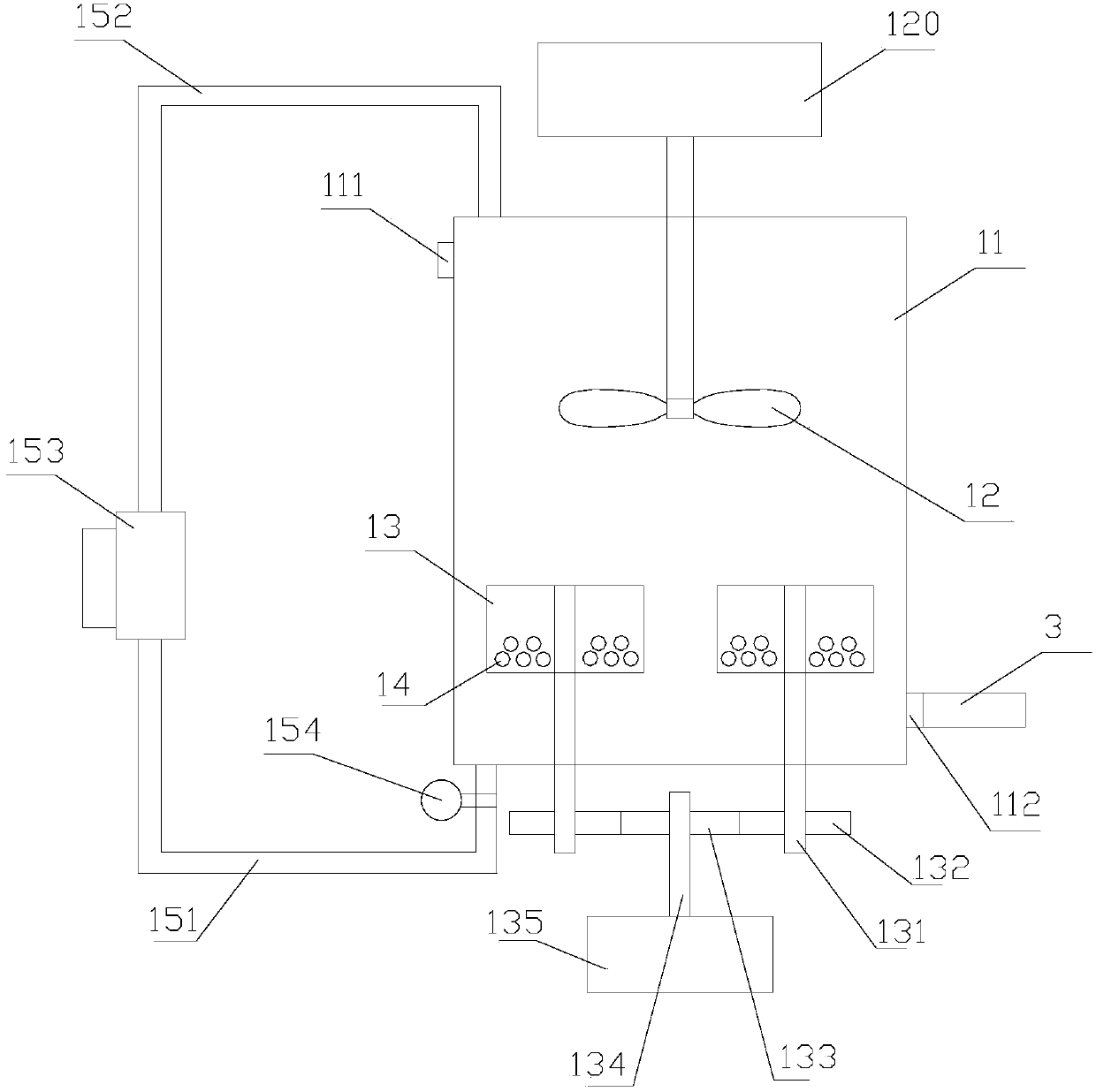

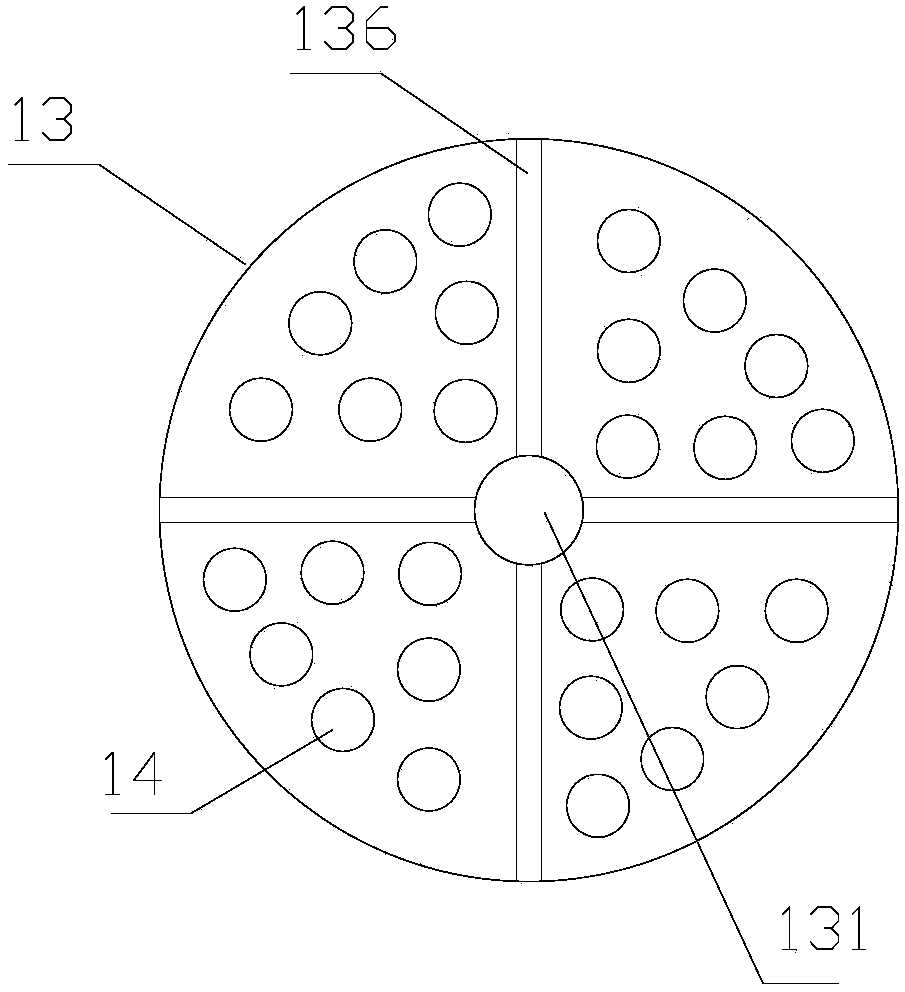

[0022] figure 1 It is the structural representation of the water-based paint grinding system with circulation hedging function of the present invention, figure 2 It is the structural representation of the circulation type preliminary grinder in this aspect, image 3 It is a top view structural schematic diagram of the grinding tank 13 of the present invention, Figure 4 It is the structural representation of the opposite type secondary grinder of the present invention, with reference to Figure 1-Figure 4 , the present invention, the water-based paint grinding system with circulation hedging function, comprises circulation type preliminary grinder, hedge type secondary grinder, grinding conveying pipe, above-mentioned circulation type primary grinder and above-mentioned hedge type secondary grinder pass through above-mentioned grinding conveyance Tube 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com