Leather-like article in sheet form, and method for their production

A manufacturing method and sheet-like technology, applied to fabrics, dyeing methods, non-woven fabrics, etc., can solve problems such as cracking due to rubbing, and achieve the effects of reduced amount, excellent strength and physical properties, and a good sense of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

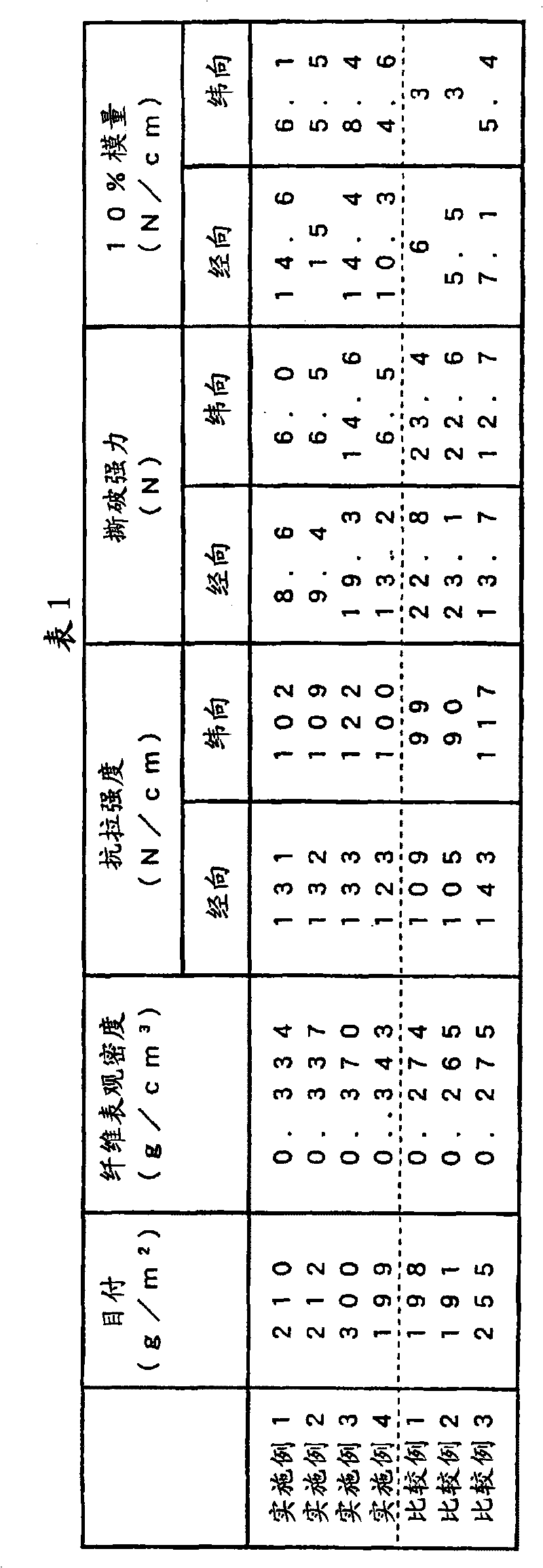

Embodiment 1

[0116] Using island-in-the-sea type composite staple fiber with single fiber fineness of 3 decitex, 36 islands, and fiber length of 51 mm, consisting of 45 parts of polystyrene as the sea component and 55 parts of polyethylene terephthalate as the island component , making a fiber web through a carding machine or a cross winder. Then pass through 1 barb type needle, at 1500 / cm 2 The weft density is processed to obtain a fiber apparent density of 0.210g / cm 3 Composite staple fiber non-woven fabric. Next, it is immersed in a 12% aqueous solution of polyvinyl alcohol (PVA1) with a degree of polymerization of 500 and a degree of saponification of 88% heated to about 95°C so that the weight of the nonwoven fabric in terms of solid content will reach 25%, while immersing in PVA, perform shrinkage treatment for 2 minutes, and dry at 100°C to remove water. The obtained sheet was treated with trichlorethylene at about 30°C until the polystyrene was completely removed to obtain ultra...

Embodiment 2

[0119] Before performing the high-speed fluid flow process, it processed similarly to Example 1 except having processed PVA1 with 95 degreeC hot water until PVA1 was completely removed. The ultrafine short fiber nonwoven fabric thus obtained was a dense sheet in which ultrafine fibers were entangled, as in Example 1. The evaluation results of its physical properties are shown in Table 1.

Embodiment 3

[0121] Using 20 parts of polystyrene as the sea component and 80 parts of polyethylene terephthalate as the island component, a single fiber fineness of 5 decitex, 25 islands, and a fiber length of 51 mm (island Except that the fineness of the components was about 0.16 dtex), it processed similarly to Example 1, and obtained the ultrafine short fiber nonwoven fabric. The ultrafine short fiber nonwoven fabric thus obtained is a dense sheet in which ultrafine fibers are entangled. The evaluation results of its physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com