A manual lifting device with automatic clutch

The technology of a clutch device and a lifting device is applied in the manual mechanism, the control mechanism of the wing leaf, the door/window accessories, etc., which can solve the problems of unbalance, easy disengagement of the clutch, and difficulty in engagement, and achieves the effect of convenient operation and reliable clutch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

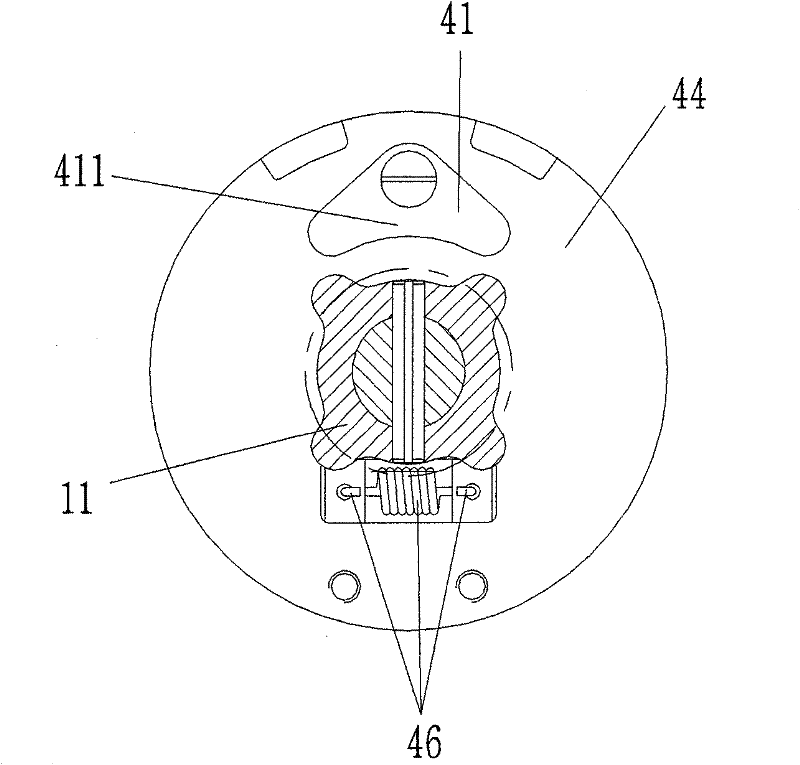

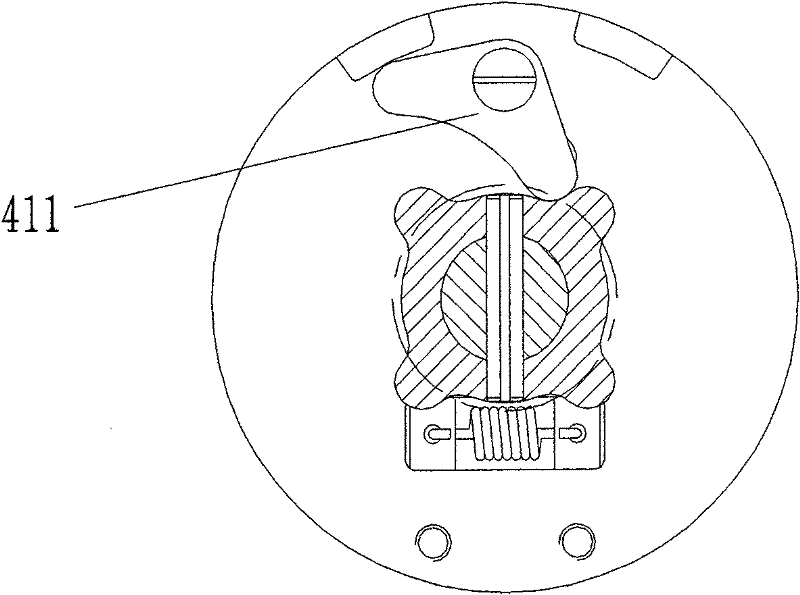

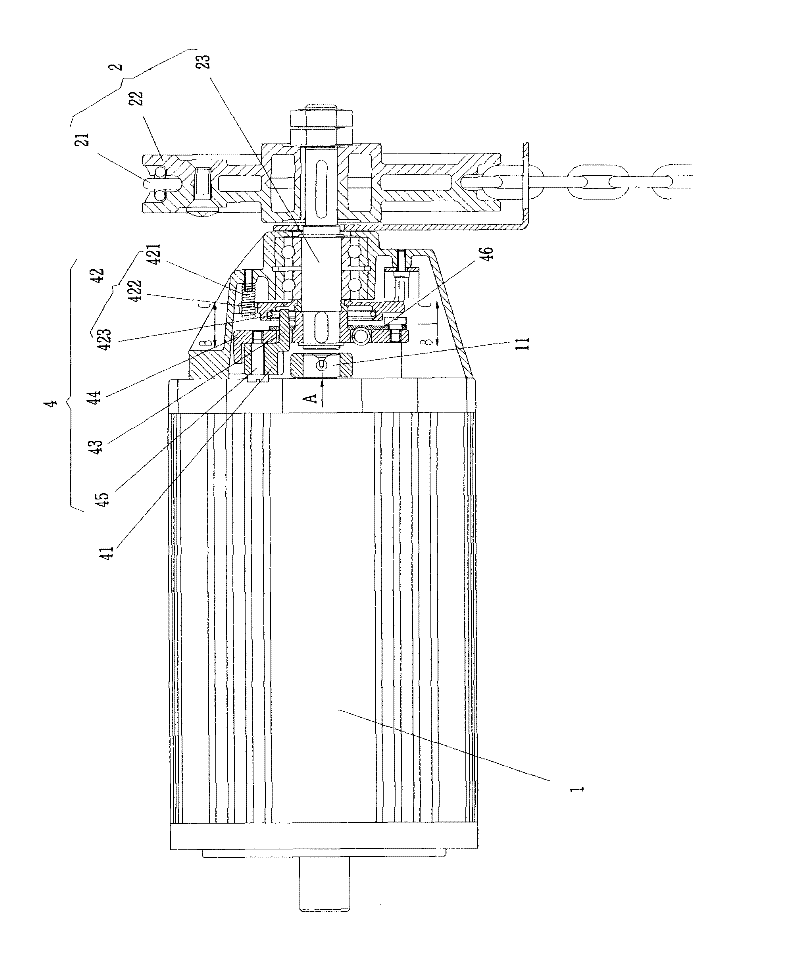

[0032] Such as figure 1 Shown is a hand-pulled lifting device with automatic clutch, which includes a motor 1, a manual rotating device 2, a motor power switch 3, and a clutch device 4; There is a radial overlapping section at the end, the overlapping section 41 of the clutch device 4 is provided with an engaging portion A and a disengaging portion 411, and the overlapping section 11 at the output end of the motor 1 is provided with an engaging portion B; the manual rotating device 2 is synchronized with the clutch device 4 Rotate; the clutch device 4 includes: a driving disc 44, a swing arm 43, a reset device 42, a pin 45; the reset device 42 includes: a back-moving spring 421, a reset disc 422, a damping ring 423; There is a tension spring 46 to reset the swing arm 43 .

[0033] Such as figure 2 As shown: when the clutch device 4 rotates until the disengagement part 411 is facing the overlapping section 11 of the output end of the motor 1, any rotation of the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com