Parallel flow evaporator and flow clapboard thereof

A kind of baffle plate and evaporator technology, applied in the direction of evaporator/condenser, refrigeration component, refrigerator, etc., can solve the problems of difficult to further improve the heat exchange efficiency of the evaporator, uneven temperature distribution, etc., and achieve good heat exchange effect. , improve the rationality, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

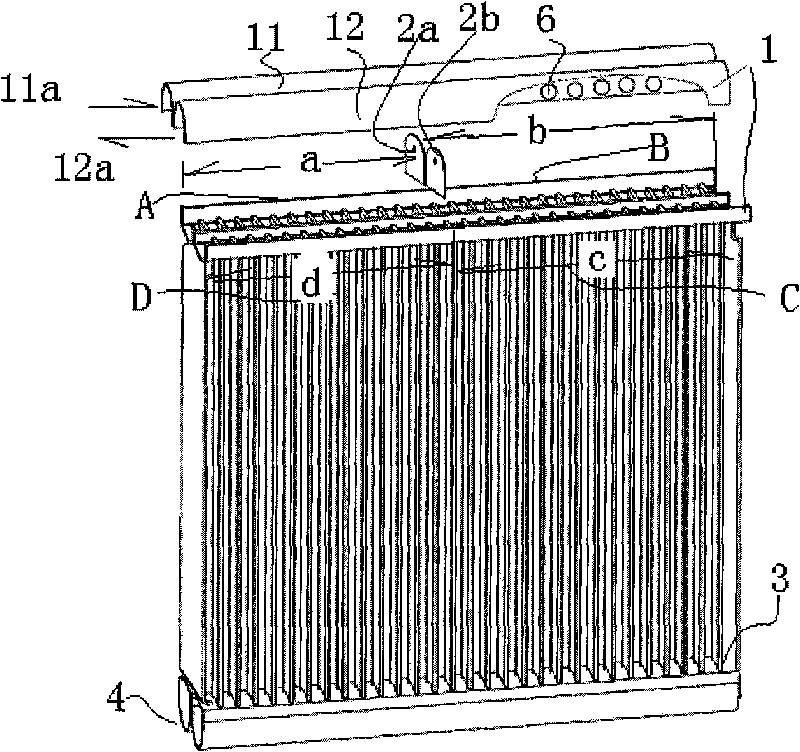

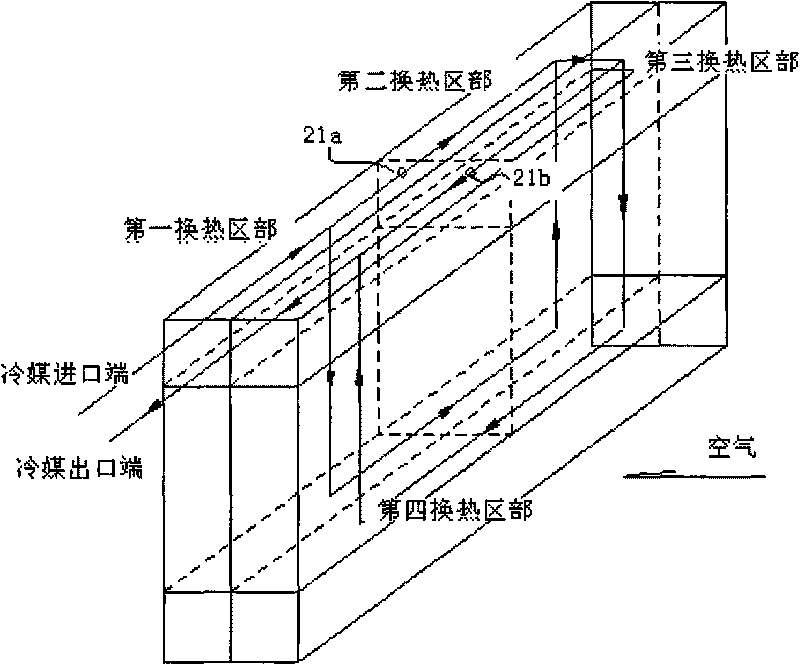

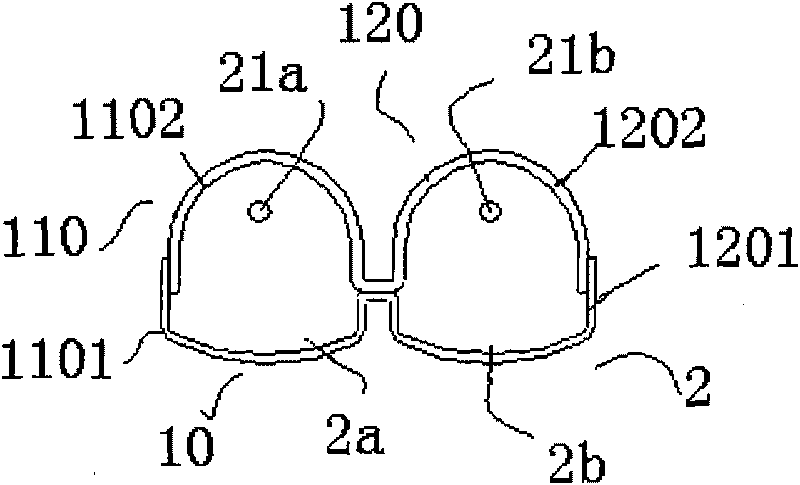

[0044] see Figure 1-4As shown, a parallel flow evaporator includes a first liquid collecting pipe 1, a second liquid collecting pipe 4, a first flow partition 2a, and a second flow partition 2b, and the first flow partition 2a is arranged in the first row In the liquid collecting pipe 11; the second flow divider 2b is installed in the second liquid collecting pipe 12; between the first liquid collecting pipe and the second liquid collecting pipe, a plurality of flat heat exchange tubes 3 for allowing the refrigerant to pass through are installed, separated The flow plate is installed in the liquid collection pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com