Method for preparing special nanometer aluminum and magnesium powder for bullets

A technology of metal nano and nano aluminum powder, applied in ammunition, warheads, offensive equipment, etc., can solve the problems of regional instability, lack of bullets for combating individual weapons, and reduction of combat personnel, so as to enhance stability and increase effective lethality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

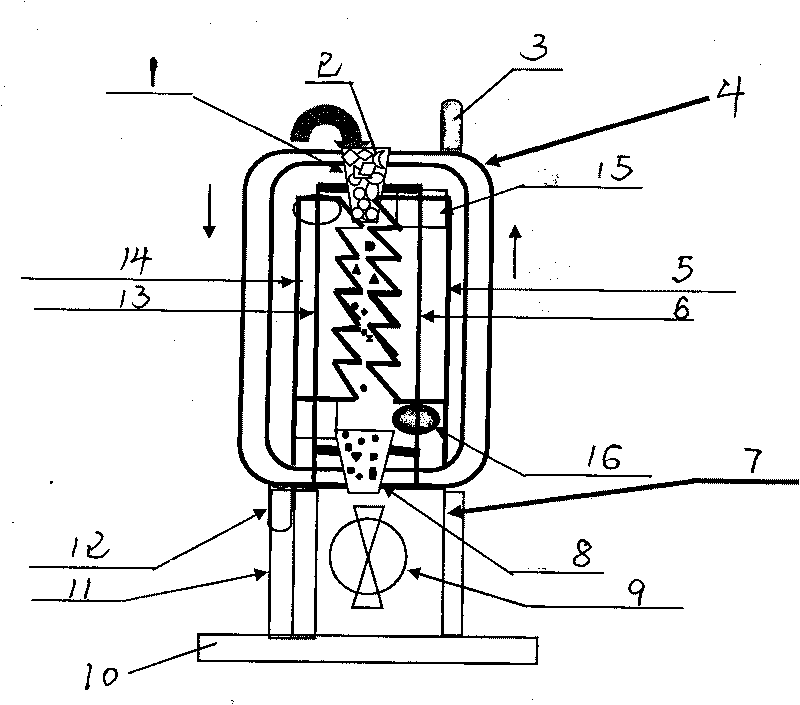

Method used

Image

Examples

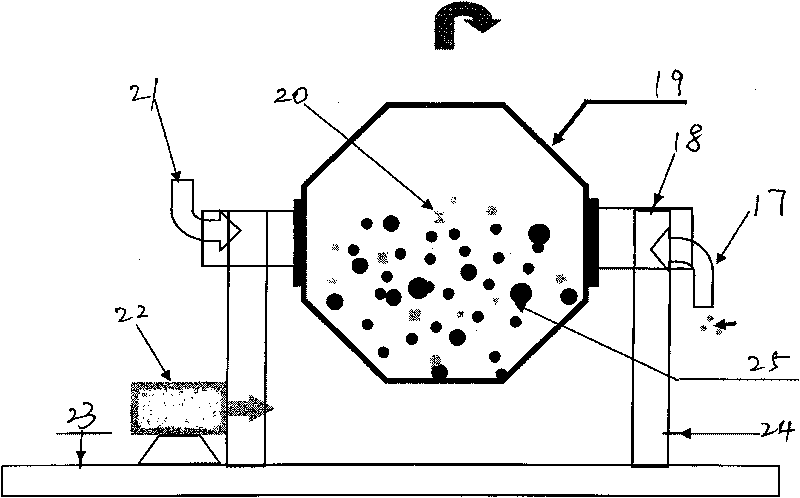

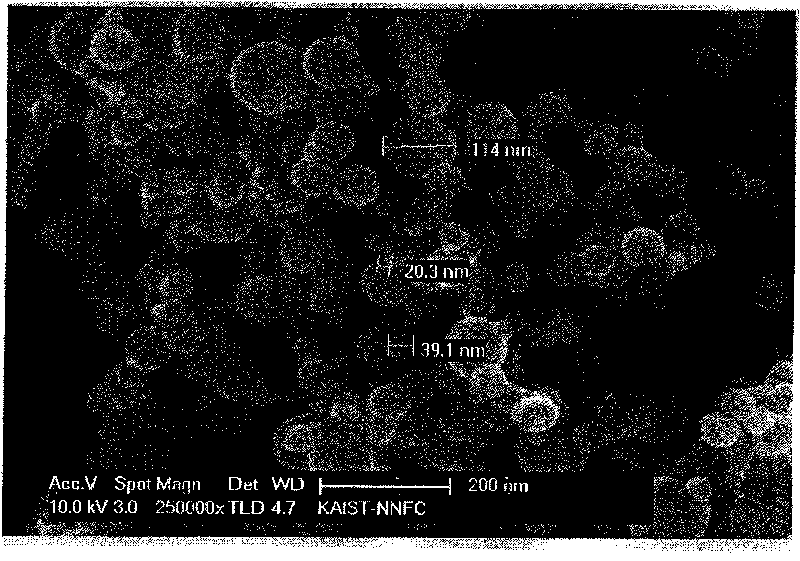

Embodiment 1

[0023] Embodiment 1, a preparation method of special metal nano-aluminum and magnesium powder for bullets is to process aluminum and magnesium raw materials into powder respectively under the condition of -5°C and setting the frequency of high-frequency cutting at 6000 times per minute Special bullet nano-aluminum powder and nano-magnesium powder whose body particle shape is spherical, and then separately sort out (50nm as an example) powder with concentrated particle distribution of D3=21nm D25=31.1nm D50=50nm D75=76.13nm D97=100.6nm Body materials, and then use the "DQ coating method" to carry out anti-oxidation coating on iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours, and then under the condition of -5°C-0°C Carry out high-speed grinding at 6000 rpm--8000 rpm, the surface tension of the powder particle material will be gradually eliminated during high-speed operation and grinding, and the grinding time is requ...

Embodiment 2

[0029] Embodiment 2, a preparation method of special metal nano-aluminum and magnesium powder for bullets, is to process aluminum and magnesium raw materials into powder respectively under the condition of 0°C and setting the frequency of high-frequency cutting at 5500 times per minute The special bullet nano-aluminum powder and nano-magnesium powder whose particle shape is spherical, and then separately sort out (50nm as an example) powder with concentrated particle distribution of D3=21nm D25=31.1nm D50=50nm D75=76.13nm D97=100.6nm material, and then use the "DQ coating method" to carry out anti-oxidation coating on the iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0030] According to the characteristics of individual weapon bullet technology, the coated powder material is input into a high-speed powder particle surface treatment machine for surface energy treatment of powder particles, so that the surface e...

Embodiment 3

[0031] Embodiment 3, a preparation method of special metal nano-aluminum and magnesium powders for bullets is to process the raw materials of aluminum and magnesium into powder respectively under the condition of -3°C and setting the frequency of high-frequency cutting at 5800 times per minute Special bullet nano-aluminum powder and nano-magnesium powder whose body particle shape is spherical, and then separately sort out (50nm as an example) powder with concentrated particle distribution of D3=21nm D25=31.1nm D50=50nm D75=76.13nm D97=100.6nm Body materials, and then use the "DQ coating method" to carry out anti-oxidation coating on iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0032] According to the characteristics of individual weapon bullet technology, the coated powder material is input into a high-speed powder particle surface treatment machine for surface energy treatment of powder particles, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap