Airtight test machine

A technology of air tightness test and air cylinder, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness and detecting the appearance of fluid at the leakage point, etc. It can solve the problems that the cylinder cannot be rotated automatically and the degree of automation is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structural features of the present invention will be further described below in conjunction with the accompanying drawings.

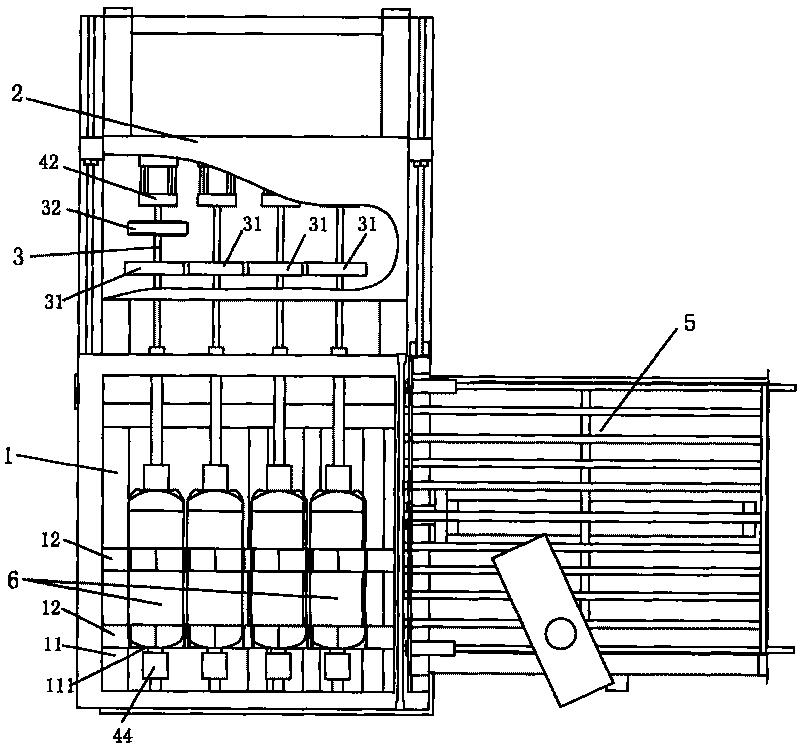

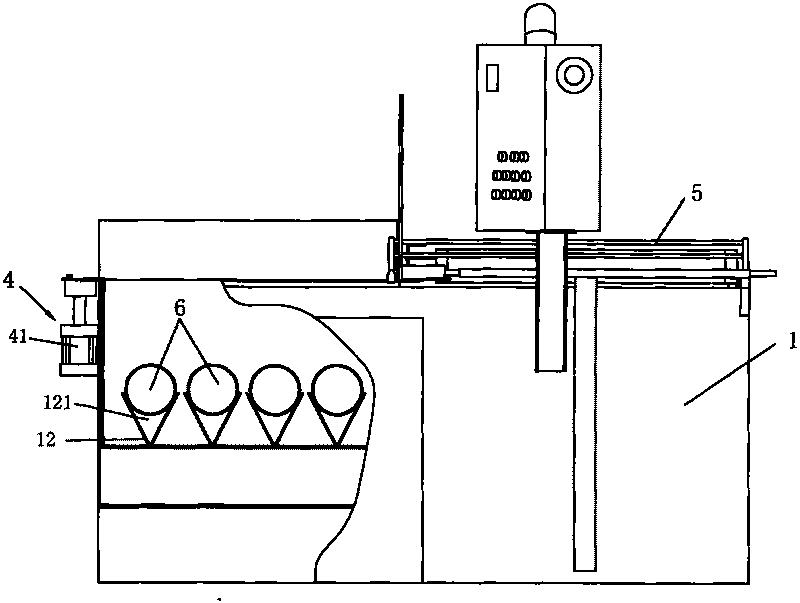

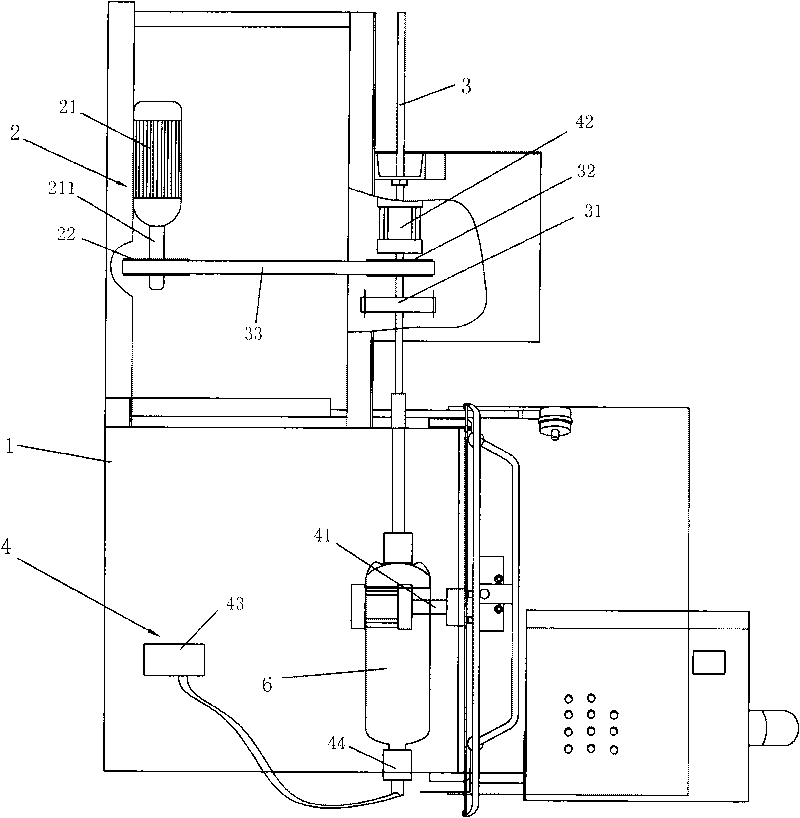

[0015] see figure 1 , figure 2 and image 3 , The airtight testing machine of the present invention includes a working box 1, a motor box 2, a number of ejector rods 3, an inflatable device 4, and a protective cover 5.

[0016] The working box 1 is equipped with a turntable 11 at the bottom, and a plurality of accommodating parts 111 for accommodating steel cylinders 6 are arranged on the turntable 11, and a bracket 12 is arranged in the middle part, and a plurality of accommodating parts 111 corresponding to the bracket 12 are arranged on the accommodating portion 121 . The accommodating portion 121 may be rhombus-shaped or V-shaped.

[0017] The motor box 2 includes a motor 21 , and a first pulley 22 is connected to a rotating shaft 211 of the motor 21 .

[0018] Several push rods 3 are all worn with gears 31, and the adjacent two gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com